Abstract

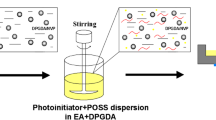

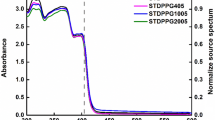

The present work focuses on the preparation of epoxy acrylate/titania materials using lithography-based additive manufacturing. A series of polymeric nanocomposite resin blends is formulated and cured with digital light processing (DLP) through three-dimensional printing studies. Epoxy acrylate oligomers are synthesized by reacting glycidyl methacrylate with acrylic acid, poly(ethylene glycol) dimethacrylate and poly(ethylene glycol) methyl ether methacrylate in the presence of triphenylphosphine as the catalyst and benzoin as the photoinitiator. The impact of TiO2 nanoparticles in various formulations is investigated, and 3D designed specimens are successfully printed with a Creality LDR002-DLP machine. The resulting materials are characterized using Fourier Transform infrared spectroscopy, mechanical and thermal analyses, allowing for the determination of their chemical and physical properties. Although all the resin formulations investigated in this study are compatible with DLP-3D printing technology, the nanoparticle-incorporated formulations required less time to UV-cure compared to the other formulations. Notably, the printed specimens containing the TiO2 nanoparticles exhibit better thermal stability and gel content. The highly crosslinked structure formation of these systems provides good dimensional stability, which is crucial for 3D printing.

Similar content being viewed by others

Availability of data and materials

The datasets generated during the present work are available from the corresponding author on reasonable request.

References

Zhakeyev A, Wang P, Zhang L, Shu W, Wang H, Xuan J (2017) Additive manufacturing: unlocking the evolution of energy materials. Adv Sci 4(10):1700187. https://doi.org/10.1002/advs.201700187

Liu S, Huang X, Peng S, Zheng Y, Wu L, Weng Z (2023) Study on the preparation of long-term stability core–shell particles/epoxy acrylate emulsion and toughening improvement for 3D printable UV-curable resin. J Polym Res 30(3):122. https://doi.org/10.1007/s10965-023-03489-w

Xu S, Fang M, Yan X (2022) Research on Rheology and Formability of SiO2 Ceramic Slurry Based on Additive Manufacturing Technology via a Light Curing Method. ACS Omega 7(36):32754–32763. https://doi.org/10.1021/acsomega.2c04541

Ning L, Chen J, Sun J, Liu Y, Yi D, Cao J (2021) Preparation and Properties of 3D Printing Light-Curable Resin Modified with Hyperbranched Polysiloxane. ACS Omega 6(37):23683–23690. https://doi.org/10.1021/acsomega.1c01232

Turna M, Şen F, Madakbaş S, Karataş S (2023) Preparation and characterization of UV-cured epoxy acrylate-based nanocomposite coatings containing organonanoclay. Polym Bull 80:7949–7969. https://doi.org/10.1007/s00289-022-04386-w

Bednarczyk P, Mozelewska K, Nowak M, Czech Z (2021) Photocurable Epoxy Acrylate Coatings Preparation by Dual Cationic and Radical Photocrosslinking. Materials 14(15):4150. https://doi.org/10.3390/ma14154150

Xiao X, Hao C (2010) Preparation of waterborne epoxy acrylate/silica sol hybrid materials and study of their UV curing behavior. Colloids Surf A Physicochem Eng Asp 359(1–3):82–87. https://doi.org/10.1016/j.colsurfa.2010.01.067

Yang Z, Wu J, Ma G, Hou C, Niu Y, Duan H, Hao X (2021) Effect of the particle sizes of silica on the properties of UV-curing matting coatings. J Coat Technol Res 18:183–192. https://doi.org/10.1007/s11998-020-00395-4

Islam MT, Dominguez A, Turley RS, Kim H, Sultana KA, Shuvo MAI, Alvarado-Tenorio B, Montes MO, Lin Y, Gardea-Torresdey NJC (2020) Development of photocatalytic paint based on TiO2 and photopolymer resin for the degradation of organic pollutants in water. Sci Total Environ 704:135406. https://doi.org/10.1016/j.scitotenv.2019.135406

Xunwen S, Liqun Z, Weiping L, Huicong L, Hui Y (2020) The synthesis of monodispersed M-CeO2/SiO2 nanoparticles and formation of UV absorption coatings with them. RSC Adv 10(8):4554–4560. https://doi.org/10.1039/c9ra08975f

Parangi T, Mishra MK (2019) Titania nanoparticles as modified photocatalysts: a review on design and development. Comment Inorg Chem 39(2):90–126. https://doi.org/10.1080/02603594.2019.1592751

Deng Y, Li S, Li X, Wang R (2020) HI-assisted fabrication of Sn-doped TiO2 electron transfer layers for air-processed perovskite solar cells with high efficiency and stability. Sol Energy Mater Sol Cells 215:110594. https://doi.org/10.1016/j.solmat.2020.110594

Ferhati H, Djeffal F, Martin N (2020) Highly improved responsivity of a self-powered UV–Visible photodetector based on TiO2/Ag/TiO2 multilayer deposited by GLAD technique: Effects of oriented columns and nano-sculptured surfaces. Appl Surf Sci 529:147069. https://doi.org/10.1016/j.apsusc.2020.147069

Yu Z, Liu H, Zhu M, Li Y, Li W (2021) Interfacial charge transport in 1D TiO2-based photoelectrodes for photoelectrochemical water splitting. Small 17(9):1903378. https://doi.org/10.1002/smll.201903378

Li Z, Li Z, Zuo C, Fang X (2022) Application of nanostructured TiO2 in UV photodetectors: A review. Adv Mater 34(28):2109083. https://doi.org/10.1002/adma.202109083

Da Silva JB, Haddow P, Bruschi ML, Cook MT (2022) Thermoresponsive poly (di (ethylene glycol) methyl ether methacrylate)-ran-(polyethylene glycol methacrylate) graft copolymers exhibiting temperature-dependent rheology and self-assembly. J Mol Liq 346:117906. https://doi.org/10.1016/j.molliq.2021.117906

Bednarczyk P, Irska I, Gziut K, Ossowicz-Rupniewska P (2021) Novel multifunctional epoxy (Meth) acrylate resins and coatings preparation via cationic and free-radical photopolymerization. Polymers 13(11):1718. https://doi.org/10.3390/polym13111718

Shen L, Li Y, Zheng J, Lu M, Wu K (2015) Modified epoxy acrylate resin for photocurable temporary protective coatings. Prog Org Coat 89:17–25. https://doi.org/10.1016/j.porgcoat.2015.07.022

Kardar P, Ebrahimi M, Bastani S, Jalili M (2009) Using mixture experimental design to study the effect of multifunctional acrylate monomers on UV cured epoxy acrylate resins. Prog Org coat 64(1):74–80. https://doi.org/10.1016/j.porgcoat.2008.07.022

Hajiali F, Tajbakhsh S, Marić M (2021) Epoxidized block and statistical copolymers reinforced by Organophosphorus–Titanium–Silicon hybrid nanoparticles: morphology and thermal and mechanical properties. ACS Omega 6(17):11679–11692. https://doi.org/10.1021/acsomega.1c00993

Voet VS, Strating T, Schnelting GH, Dijkstra P, Tietema M, Xu J, Woortman AJ, Loos K, Jager J, Folkersma R (2018) Biobased acrylate photocurable resin formulation for stereolithography 3D printing. ACS Omega 3(2):1403–1408. https://doi.org/10.1021/acsomega.7b01648

Jia Y, Spiegel CA, Welle A, Heißler S, Sedghamiz E, Liu M, Wenzel W, Hackner M, Spatz JP, Tsotsalas M, Blasco E (2022) Covalent adaptable microstructures via combining two‐photon laser printing and alkoxyamine chemistry: toward living 3D microstructures. Adv Funct Mater 2207826. https://doi.org/10.1002/adfm.202207826

Zhang K, Li L, Chen X, Lu C, Ran J (2022) Controlled preparation and properties of acrylic acid epoxy-acrylate composite emulsion for self-crosslinking coatings. J Appl Polym Sci 139(1):51441. https://doi.org/10.1002/app.51441

Tekin D, Birhan D, Kiziltas H (2020) Thermal, photocatalytic, and antibacterial properties of calcinated nano-TiO2/polymer composites. Mater Chem Phys 251:123067. https://doi.org/10.1016/j.matchemphys.2020.123067

Wu M, Zhang F, Yu J, Zhou H, Zhang D, Hu C, Huang J (2014) Fabrication and evaluation of light-curing nanocomposite resins filled with surface-modified TiO2 nanoparticles for dental application. Iran Polym J 23:513–524. https://doi.org/10.1007/s13726-014-0246-7

Hara S, Tomono M, Fukumoto K, Kubodera M, Kato N, Kaneko T, Toyama T, Shimizu S, Ikake H (2020) Melt-moldable copolymethacrylate/titania thermoreversible polymer networks with shape memory. ACS Appl Polym Mater 2(12):5654–5663. https://doi.org/10.1021/acsapm.0c00967

Al-Bati S, Jumali MHH, Khatatbeh I, Al-Asbahi BA (2021) Effect of TiO2 nanoparticles on energy transfer mechanism in ternary nanocomposite conjugated polymer blend. Optik 245:167718. https://doi.org/10.1016/j.ijleo.2021.167718

Grauzeliene S, Schuller AS, Delaite C, Ostrauskaite J (2023) Development and digital light processing 3d printing of a vitrimer composed of glycerol 1, 3-diglycerolate diacrylate and tetrahydrofurfuryl methacrylate. ACS Appl Polym Mater 5(9):6958–6965. https://doi.org/10.1021/acsapm.3c01018

Masoumi H, Mirfendereski SM (2019) Modification of physical and thermal characteristics of stearic acid as a phase change materials using TiO2-nanoparticles. Thermochim Acta 675:9–17. https://doi.org/10.1016/j.tca.2019.02.015

Kanemoto SO, Gouthaman S, Venkatesh M, Cheumani YAM, Ndikontar MK, Suguna Lakshmi M (2022) Thermal stability of phosphorus-based epoxy/clay composites and its effect on flame-retardation properties of leather. Iran Polym J 31(12):1583–1594. https://doi.org/10.1007/s13726-022-01100-5

Kanemoto SO, Gouthaman S, Venkatesh M, Cheumani AM, Ndikontar MK, Suguna Lakshmi M (2021) Thermal performance of polyurethane nanocomposite from phosphorus and nitrogen-containing monomer, polyethylene glycol and polydimethylsiloxane for thermal energy storage applications. J Therm Anal Calorim 146:2435–2444. https://doi.org/10.1007/s10973-020-10478-4

Wu Q, Hu Y, Tang J, Zhang J, Wang C, Shang Q, Feng G, Liu C, Zhou Y, Lei W (2018) High-performance soybean-oil-based epoxy acrylate resins: “Green” synthesis and application in UV-curable coatings. ACS Sustain Chem Eng 6(7):8340–8349. https://doi.org/10.1021/acssuschemeng.8b00388

Desai PD, Jagtap RN (2021) Synthesis and characterization of fiber-reinforced resorcinol epoxy acrylate applied to stereolithography 3D printing. ACS Omega 6(46):31122–31131. https://doi.org/10.1021/acsomega.1c04566

Siraj S, Al-Marzouqi AH, Iqbal MZ, Ahmed W (2022) Impact of micro silica filler particle size on mechanical properties of polymeric based composite material. Polymers 14(22):4830. https://doi.org/10.3390/polym14224830

Karaca TH, Çiçek B, Aydoğmuş T, Sun Y (2022) The effect of graphene-nanoplatelet and nano-teflon on mechanical properties of UV photo-resin 3D printer products. Polym -Plast Technol Mater 61(12):1298–1307. https://doi.org/10.1080/25740881.2022.2061862

Smith RL, Mecholsky JJ, Freiman SW (2009) Estimation of fracture energy from the work of fracture and fracture surface area: I. Stable crack growth Int J Fract 156:97–102. https://doi.org/10.1007/s10704-009-9350-7

Acknowledgements

The authors would like to thank CSIR-CLRI for financial support through the proposed research work MLP-13/2023/Communication No.1886, and acknowledge CLRI-CATERS for the research facilities extended to carry out this work.

Funding

Central Leather Research Institute,MLP-13/2023/Communication No.1886,Suguna Lakshmi Madurai

Author information

Authors and Affiliations

Contributions

Saieswari Ganesamoorthy: Conceptualization, Methodology, Investigation, Writing—Original Draft. Harini Prabhakaran: Methodology, Investigation, Writing & Reviewing. Stanley Olivier Kanemoto: Conceptualization, Methodology, Investigation, Writing—Original Draft, Visualization, Reviewing & Editing. Arnaud Maxime Cheumani Yona: Validation, Resources. Suguna Lakshmi Madurai: Project Administration, Writing – Review & Editing, Supervision, Funding acquisition.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors have no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ganesamoorthy, S., Prabhakaran, H., Kanemoto, S.O. et al. Titanium nanoparticles bonded polyacrylates with enhanced properties fabricated using DLP 3D printing. J Polym Res 31, 21 (2024). https://doi.org/10.1007/s10965-023-03862-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03862-9