Abstract

In this contribution, isosorbide dinonanoate (SDN), an environmentally sustainable plasticizer for polypropylene (PP), is successfully synthesized by virtue of esterification reaction using isosorbide and nonanoic acid with the reaction temperature of 120 °C, and the reaction time of 5 h. When the corporation of plasticizer SDN into PP matrix is the value of 15 phr, the impact strength of PP blends reaches 121 J/m, the dramatically increase of 384% compare to that of PP. DMA results shows that the glass transition temperature (Tg) of PP blends gradually decline with the increasing amount of SDN, indicating the efficient plasticization action of the SDN. It is suggested that SDN can be feasibly inserted into the non-polar matrix and then more evenly dispersed in matrix, herein, it will increase the distance between the polymer chains, improving the mobility of the molecular chains and the processing performance of the polymers. Furthermore, the plasticizing effect and environmental friendliness of SDN can be a potential replacement for o-phenyl plasticizers in the industry in the future.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author, [author L], upon reasonable request.

References

Zhu J, Liu XQ (2018) Bio-based polymer materials. Science Press, Beijing

Bocque M, Voirin C, Lapinte V, Caillol S, Robin JJ (2016) Petro-based and bio-based plasticizers: Chemical structures to Plasticizing properties. J Polym Sci A Polym Chem 54:11–33

Hu YY, Sang R, Vroemans R, Mollaert G, Razzaq R, Neumann H, Junge H, Franke R, Jackstell R, Maes BUW, Beller M (2023) Efficient synthesis of Novel plasticizers by Direct Palladium-Catalyzed Di- or multi-carbonylations. Angew Chem Int Ed Engl. https://doi.org/10.1002/anie.202214706

Daniels PH (2009) A brief overview of theories of PVC plasticization and methods used to evaluate PVC-plasticizer interaction. J Vinyl Addit Technol 15:219–223

Latini G, Felice CD, Verrotti A (2004) Plasticizers, infant nutrition and reproductive health. Reprod Toxicol 19:27–33

Chiellini F, Ferri M, Latini G (2011) Physical-chemical assessment of di-(2-ethylhexyl)-phthalate leakage from poly(vinyl chloride) endotracheal tubes after application in high-risk newborns. Int J Pharm 409:57–61

Chiellini F, Ferri M, Morelli A, Dipaola L, Latini G (2013) Perspectives on alternatives to phthalate plasticized poly(vinyl chloride) in medical devices applications. Prog Polym Sci 38:1067–1088

Hines CJ, Hopf NB, Deddens JA, Silva MJ, Calafat AM (2012) Occupational exposure to diisononyl phthalate (DiNP) in polyvinyl chloride processing operations. Int Arch Occup Environ Health 85:317–325

Lithner D, Larsson A, Dave G (2011) Environmental and health hazard ranking and assessment of plastic polymers based on chemical composition. Sci Total Environ 409:3309–3324

Khasin LG, Della Rosa J, Petersen N, Moeller J, Kriegsfeld LJ, Lishko PV (2020) The impact of Di-2-Ethylhexyl phthalate on sperm fertility. Front Cell Dev Biol. https://doi.org/10.3389/fcell.2020.00426

Zhang Y, Mu XY, Gao RF, Geng YQ, Liu XQ, Chen XM, Wang YH, Din YB, Wang YX, He JL (2018) Foetal-neonatal exposure of Di (2-ethylhexyl) phthalate disrupts ovarian development in mice by inducing autophagy. J Hazard Mater 358:101–112

Wang JJ, Tian Y, Li MH, Feng YQ, Kong L, Zhang FL, Shen W (2021) Single-cell transcriptome dissection of the toxic impact of Di (2-ethylhexyl) phthalate on primordial follicle assembly. Theranostics 11:4992–5009

Mekonnen T, Mussone P, Khalil H, Bressler D (2013) Progress in bio-based plastics and plasticizing modifications. J Mater Chem A Mater 1:13379–13398

Meier MAR (2014) Sustainable polymers: reduced environmental impact, renewable raw materials and catalysis. Green Chem 16:1672–1672

Saygin D, Gielen DJ, Draeck M, Worrell E, Patel MK (2014) Assessment of the technical and economic potentials of biomass use for the production of steam, chemicals and polymers. Renew Sustain Energy Rev 40:1153–1167

Plass C, Adebar N, Hiessl R, Kleber J, Grimm A, Langsch A, Otter R, Liese A, Gröger H (2021) Structure-performance guided design of sustainable plasticizers from Biorenewable Feedstocks. Eur J Org Chem 2021:6086–6096

Kumar S (2019) Recent developments of biobased plasticizers and their effect on mechanical and thermal properties of poly(vinyl chloride): a review. Ind Eng Chem Res 58:11659–11672

Hao YY, Tian AP, Zhu J, Fan JS, Yang Y (2020) Synthesis and evaluation of Bio-based plasticizers from 5-Hydroxymethyl-2-Furancarboxylic acid for poly(vinyl chloride. Ind Eng Chem Res 59:18290–18297

Hao YY, Wang GY, Shui XX, Tian AP, Yang Y, Zhu J (2021) Design and synthesis of HFCA-based plasticizers with asymmetrical alkyl chains for poly(vinyl chloride). J Appl Polym Sci 138:e51410

Liang XJ, Wu FJ, Xie QL, Wu ZY, Cai JJ, Zheng CW, Fu JH, Nie Y (2021) Insights into biobased epoxidized fatty acid isobutyl esters from biodiesel: Preparation and application as plasticizer. Chin J Chem Eng 44:41–50

Chaochanchaikul K, Pongmuksuwan P (2021) Infuence of ozonized soybean oil as a biobased plasticizer on the toughness of polylactic acid. J Polym Environ 30:1095–1105

Gama N, Santos R, Godinho B, Silva R, Ferreira A (2019) Triacetin as a secondary PVC Plasticizer. J Polym Environ 27:1294–1301

Yang D, Peng XW, Zhong LX, Cao XF, Chen W, Zhang XM, Liu SJ, Sun RC (2014) Green films from renewable resources: Properties of epoxidized soybean oil plasticized ethyl cellulose films. Carbohydr Polym 103:198–206

Nihul PG, Mhaske ST, Shertukde VV (2014) Epoxidized rice bran oil (ERBO) as a plasticizer for poly(vinyl chloride) (PVC). Iran Polym J 23:599–608

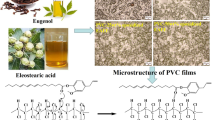

Chen J, Liu ZS, Li K, Huang JR, Nie XA, Zhou YH (2015) Synthesis and application of a natural plasticizer based on cardanol for poly(vinyl chloride). J Appl Polym Sci 132:42465

Chen J, Liu ZS, Li XY, Liu P, Jiang JC, Nie XA (2016) Thermal behavior of epoxidized cardanol diethyl phosphate as novel renewable plasticizer for poly(vinyl chloride). Polym Degrad Stab 126:58–64

Chen J, Liu ZS, Jiang JC, Nie XA, Zhou YH, Murray RE (2015) A novel biobased plasticizer of epoxidized cardanol glycidyl ether: synthesis and application in soft poly(vinyl chloride). Films RSC Adv 5:56171–56180

Satavalekar SD, Savvashe PB, Mhaske ST (2016) Triester-amide based on thiophene and ricinoleic acid as an innovative primary plasticizer for poly(vinyl chloride). RSC Adv 6:115101–115112

Maiza M, Benaniba MT, Massardier-Nageotte V (2016) Plasticizing effects of citrate esters on properties of poly(lactic acid). J Polym Eng 36:371–380

Kim H, Ji YS, Rehman SU, Choi MS, Gye MC, Yoo HH (2019) Pharmacokinetics and metabolism of acetyl triethyl citrate, a water-soluble plasticizer for pharmaceutical polymers in rats. Pharmaceutics 11:162

Liu JY, Yuan R, Sang Q, Dang L, Gao L, Xu BH, Xu SI (2022) Effect of acetylated citrate plasticizer on mechanical properties of poly (vinyl chloride). Mater Chem Phys 295:127068

Harte I, Birkinshaw C, Jones E, Kennedy J, DeBarra E (2013) The effect of citrate ester plasticizers on the thermal and mechanical properties of poly(DL-lactide). J Appl Polym Sci 127:1997–2003

Tsou CH, Suen MC, Yao WH, Yeh JT, Wu CS, Tsou CY, Chiu SH, Chen JC, Wang RY, Lin SM, Hung WS, De Guzman M, Hu CC, Lee KR (2014) Preparation and characterization of bioplastic-based green renewable composites from tapioca with acetyl tributyl citrate as a plasticizer. Materials 7:5617–5632

Yin B, Hakkarainen M (2011) Oligomeric Isosorbide Esters as alternative renewable resource plasticizers for PVC. J Appl Polym Sci 119:2400–2407

Adhikari B, Chaudhary DS, Clerfeuille E (2010) Effect of plasticizers on the moisture migration behavior of low-amylose starch films during drying. Dry Technol 28:468–480

Hou BY, Ren L, Fu DM, Jiang YY, Zhang MY, Zhang HX (2021) Novel environmentally sustainable xylitolbased plasticizer: synthesis and application. J Polym Res 28:337

Zdanowicz M, Staciwa P, Spychaj T (2019) Low transition temperature mixtures (LTTM) containing sugars as Potato Starch plasticizers. Starch-Starke 71:1900004

Han Y, Weng YX, Zhang CL (2023) Development of biobased plasticizers with synergistic effects of plasticization, thermal stabilization, and migration resistance: a review. J Vinyl Addit Technol. https://doi.org/10.1002/vnl.22048

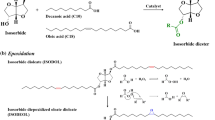

Han Y, Zhang CL, Yang Y, Weng YX, Ma PM, Xu PW (2023) Epoxidized isosorbide-based esters with long alkyl chains as efficient and enhanced thermal stability and migration resistance PVC plasticizers. Polym Test. https://doi.org/10.1016/j.polymertesting.2023.108048

Yang Y, Huang JC, Zhang RY, Zhu J (2017) Designing bio-based plasticizers: effect of alkyl chain length on plasticization properties of isosorbide diesters in PVC blends. Mater Des 126:29–36

Yang Y, Xiong Z, Zhang LS, Tang ZB, Zhang RY, Zhu J (2016) Isosorbide dioctoate as a green plasticizer for poly(lactic acid). Mater Des 91:262–268

Yang Y, Xiong Z, Zhang LS, Tang ZB, Zhang RY, Zhu J (2016) Effect of isosorbol-based plasticizers on thermal, mechanical properties and crystalline behavior of PLA. Plast Addit 3:57–62

Jiang YY, Ren L, Wu GH, Guo W, Guan XF, Zhang MY, Zhang HX (2022) An environmentally sustainable isosorbide-based plasticizer for biodegradable poly(butylene succinate). J Polym Eng 42:331–342

Li WB, Ren L, Tao ZJ, Shuai JX, Ma H, Zhao HM (2021) The design and preparation of isosorbide-based plasticizer and its application in poly(vinyl chloride). Eng Plast Appl 49:123–126

Kirkpatrick A (1940) Some relations between molecular structure and plasticizing effect. J Appl Phys 11:255–261

Flory TGF Jr (1950) Second-order transition temperatures and related properties of polystyrene.I. Influence of molecular weight. J Appl Phys 21:581–591

Zhang KX, Du J, Du GF (2014) Material synthesis and preparation research. China Water & Power Press, Beijing

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interest

The authors declare no competing financial interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Song, T., Ren, L., Li, W.B. et al. An eco-friendly sustainable plasticizer from isosorbide and nonanoic acid: synthesis and application. J Polym Res 31, 1 (2024). https://doi.org/10.1007/s10965-023-03837-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03837-w