Abstract

The potential of ultrasonication as a technique to enhance the production of polymer nanocomposites is examined in this review paper. Polymer nanocomposites have been widely employed in recent years because of their remarkable mechanical, electrical, and optical properties. The article focuses on the application of several synthesis techniques, including solvent casting, 3D printing, electrospinning, and template synthesis. It has been established that uniformly dispersing nanoparticles inside the polymer matrix during ultrasonication can greatly improve the quality of nanocomposites. Recent research has shown that nanocomposites made using ultrasonication have improved mechanical and thermal stability. However, scaling up these techniques remains a challenge and requires further research.

Similar content being viewed by others

References

Sundarram S, Kim YH, Li W (2015) Preparation and characterization of poly(ether imide) nanocomposites and nanocomposite foams. Manuf Nanocompos Eng Plast Elsevier 61–85.https://doi.org/10.1016/B978-1-78242-308-9.00004-5

Jiménez A, Vargas M, Chiralt A (2016) Antimicrobial nanocomposites for food packaging applications: novel approaches. Novel Approach Nanotechnol Food 347–386. https://doi.org/10.1016/B978-0-12-804308-0.00011-X

Kumar K, Ghosh PK, Kumar A (2016) Improving mechanical and thermal properties of TiO2-epoxy nanocomposite. Compos B Eng 97:353–360. https://doi.org/10.1016/J.COMPOSITESB.2016.04.080

Sanchez C, Lebeau B, Chaput F, Boilot J-P (2003) Optical Properties of Functional Hybrid Organic-Inorganic Nanocomposites. Adv Mater 15(23):1969–1994. https://doi.org/10.1002/adma.200300389

Njuguna J, Pielichowski K (2003) Polymer Nanocomposites for Aerospace Applications: Properties. Adv Eng Mater 5(11):769–778. https://doi.org/10.1002/adem.200310101

Mosmeri H, Tasharrofi S, Alaie E, Hassani SS (2018) Controlled-release oxygen nanocomposite for bioremediation of benzene contaminated groundwater. New Polym Nanocompos Environ Remed 601–622. https://doi.org/10.1016/B978-0-12-811033-1.00023-8

Ji L, Meduri P, Agubra V, Xiao X, Alcoutlabi M (2016) Graphene-Based Nanocomposites for Energy Storage. Adv Energy Mater 6(16):1502159. https://doi.org/10.1002/aenm.201502159

Haghighi H, Licciardello F, Fava P, Siesler HW, Pulvirenti A (2020) Recent advances on chitosan-based films for sustainable food packaging applications. Food Packag Shelf Life 26

Holder E, Tessler N, Rogach AL (2008) Hybrid nanocomposite materials with organic and inorganic components for opto-electronic devices. J Mater Chem 18(10):1064. https://doi.org/10.1039/b712176h

Feldman D (2016) Polymer nanocomposites in medicine. J Macromol Sci Part A 53(1):55–62. https://doi.org/10.1080/10601325.2016.1110459

Rhim J-W, Ng PKW (2007) Natural Biopolymer-Based Nanocomposite Films for Packaging Applications. Crit Rev Food Sci Nutr 47(4):411–433. https://doi.org/10.1080/10408390600846366

Di Y, Iannace S, di Maio E, Nicolais L (2003) Nanocomposites by melt intercalation based on polycaprolactone and organoclay. J Polym Sci B Polym Phys 41(7):670–678. https://doi.org/10.1002/polb.10420

Liu X, Wu Q (2001) PP/clay nanocomposites prepared by grafting-melt intercalation. Polymer (Guildf) 42(25):10013–10019. https://doi.org/10.1016/S0032-3861(01)00561-4

Bhanvase BA, Sonawane SH (2014) Ultrasound assisted in situ emulsion polymerization for polymer nanocomposite: A review. Chem Eng Proc Proc Intensific 85:86–107. https://doi.org/10.1016/j.cep.2014.08.007

Pomogailo AD (2005) Polymer Sol-Gel Synthesis of Hybrid Nanocomposites. Colloid J 67(6):658–677. https://doi.org/10.1007/s10595-005-0148-7

Amiri S, Rahimi A (2016) Hybrid nanocomposite coating by sol–gel method: a review. Iranian Polym J 25(6):559–577. https://doi.org/10.1007/s13726-016-0440-x

Chandra A, Turng L-S, Gopalan P, Rowell RM, Gong S (2008) Study of utilizing thin polymer surface coating on the nanoparticles for melt compounding of polycarbonate/alumina nanocomposites and their optical properties. Compos Sci Technol 68(3–4):768–776. https://doi.org/10.1016/j.compscitech.2007.08.027

Philip MA, Natarajan U, Nagarajan R (2014) Acoustically-enhanced particle dispersion in polystyrene/alumina nanocomposites. Adv Nano Res 2(2):121–133. https://doi.org/10.12989/anr.2014.2.2.121

Pinjari DV, Pandit AB (2010) Cavitation milling of natural cellulose to nanofibrils. Ultrason Sonochem 17(5):845–852. https://doi.org/10.1016/J.ULTSONCH.2010.03.005

Price GJ, Nawaz M, Yasin T, Bibi S (2018) Sonochemical modification of carbon nanotubes for enhanced nanocomposite performance. Ultrason Sonochem 40:123–130. https://doi.org/10.1016/J.ULTSONCH.2017.02.021

Badnore AU, Pandit AB (2015) Synthesis of nanosized calcium carbonate using reverse miniemulsion technique: Comparison between sonochemical and conventional method. Chem Eng Proc Proc Intensific 98:13–21. https://doi.org/10.1016/J.CEP.2015.10.003

Rennhofer H, Zanghellini B (2021) Dispersion State and Damage of Carbon Nanotubes and Carbon Nanofibers by Ultrasonic Dispersion: A Review. Nanomaterials 11(6):1469. https://doi.org/10.3390/nano11061469

Pollet BG, Ashokkumar M (2019) Introduction to Ultrasound, Sonochemistry and Sonoelectrochemistry. Cham: Springer International Publishing. https://doi.org/10.1007/978-3-030-25862-7

Agarwal US, Nisal A, Joseph R (2007) PET-SWNT nanocomposites through ultrasound assisted dissolution-evaporation.Eur Polym J 43(6):2279–2285. https://doi.org/10.1016/j.eurpolymj.2007.03.020

Raso J, Mañas P, Pagán R, Sala FJ (1999) Influence of different factors on the output power transferred into medium by ultrasound. Ultrason Sonochem 5(4):157–162. https://doi.org/10.1016/S1350-4177(98)00042-X

Huang J, Yang Z, Yang B, Wang R, Wang T (2014) Ultrasound assisted polymerization for synthesis of ZnO/Polypyrrole composites for zinc/nickel rechargeable battery. J Power Sour 271:143–151. https://doi.org/10.1016/j.jpowsour.2014.07.140

Lahelin M, Annala M, Nykänen A, Ruokolainen J, Seppälä J (2011) In situ polymerized nanocomposites: Polystyrene/CNT and Poly(methyl methacrylate)/CNT composites. Compos Sci Technol 71(6):900–907. https://doi.org/10.1016/j.compscitech.2011.02.005

Santos HM, Lodeiro C, Capelo-Martinez JL (2009) The Power of Ultrasound. In Ultrasound in Chemistry, Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA, pp. 1–16. https://doi.org/10.1002/9783527623501.ch1

Santos H, Capelo J (2007) Trends in ultrasonic-based equipment for analytical sample treatment. Talanta 73(5):795–802. https://doi.org/10.1016/j.talanta.2007.05.039

Frømyr TR, Hansen FK, Olsen T (2012) The Optimum Dispersion of Carbon Nanotubes for Epoxy Nanocomposites: Evolution of the Particle Size Distribution by Ultrasonic Treatment. J Nanotechnol 2012:1–14. https://doi.org/10.1155/2012/545930

Ávila-Orta CA et al (2019) ‘Ultrasound-Assisted Melt Extrusion of Polymer Nanocomposites’, in Nanocomposites - Recent Evolutions IntechOpen. https://doi.org/10.5772/intechopen.80216

Rane AV, Kanny K, Abitha VK, Thomas S (2018) Methods for Synthesis of Nanoparticles and Fabrication of Nanocomposites. In Synthesis of Inorganic Nanomaterials, Elsevier, pp. 121–139. https://doi.org/10.1016/B978-0-08-101975-7.00005-1

Adnan M, Dalod A, Balci M, Glaum J, Einarsrud M-A (2018) In Situ Synthesis of Hybrid Inorganic-Polymer Nanocomposites. Polymers (Basel) 10(10):1129. https://doi.org/10.3390/polym10101129

Guo Q et al (2014) Comparison of in Situ and ex Situ Methods for Synthesis of Two-Photon Polymerization Polymer Nanocomposites. Polymers (Basel) 6(7):2037–2050. https://doi.org/10.3390/polym6072037

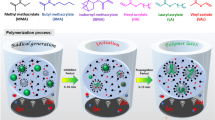

Cao Y, Zheng Y, Pan G (2008) Radical generation process studies of the cationic surfactants in ultrasonically irradiated emulsion polymerization. Ultrason Sonochem 15(4):320–325. https://doi.org/10.1016/j.ultsonch.2007.07.002

Bhanvase BA, Pinjari DV, Gogate PR, Sonawane SH, Pandit AB (2012) Synthesis of exfoliated poly(styrene-co-methyl methacrylate)/montmorillonite nanocomposite using ultrasound assisted in situ emulsion copolymerization. Chem Eng J 181–182:770–778. https://doi.org/10.1016/j.cej.2011.11.084

Dhatarwal P, Sengwa RJ (2021) Superior optical and dielectric properties of ultrasonic-assisted solution-cast prepared PMMA/MMT nanocomposite films. Funct Compos Struct 3(2)

Cherifi Z et al (2023) Ultrasound-promoted preparation of cellulose acetate/organophilic clay bio-nanocomposites films by solvent casting method. Polym Bull 80(2):1831–1843. https://doi.org/10.1007/s00289-022-04129-x

Dinari M, Mallakpour S (2014) Ultrasound-assisted one-pot preparation of organo-modified nano-sized layered double hydroxide and its nanocomposites with polyvinylpyrrolidone. J Polym Res 21(2):350. https://doi.org/10.1007/s10965-013-0350-y

Mallakpour S, Dinari M (2013) Enhancement in thermal properties of poly(vinyl alcohol) nanocomposites reinforced with Al 2 O 3 nanoparticles. J Reinf Plast Compos 32(4):217–224. https://doi.org/10.1177/0731684412467236

Soltani R, Dinari M, Mohammadnezhad G (2018) Ultrasonic-assisted synthesis of novel nanocomposite of poly(vinyl alcohol) and amino-modified MCM-41: A green adsorbent for Cd(II) removal. Ultrason Sonochem 40:533–542. https://doi.org/10.1016/j.ultsonch.2017.07.045

Safadi B, Andrews R, Grulke EA (2002) Multiwalled carbon nanotube polymer composites: Synthesis and characterization of thin films. J Appl Polym Sci 84(14):2660–2669. https://doi.org/10.1002/app.10436

Sengwa RJ, Choudhary S (2014) Dielectric properties and fluctuating relaxation processes of poly(methyl methacrylate) based polymeric nanocomposite electrolytes. J Phys Chem Solids 75(6):765–774. https://doi.org/10.1016/j.jpcs.2014.02.008

Buruga K, Kalathi JT, Kim K-H, Ok YS, Danil B (2018) Polystyrene-halloysite nano tube membranes for water purification. J Ind Eng Chem 61:169–180. https://doi.org/10.1016/j.jiec.2017.12.014

Peng B et al (2011) Effects of ultrasound on the morphology and properties of propylene-based plastomer/nanosilica composites. Polym J 43(1):91–96. https://doi.org/10.1038/pj.2010.95

Chen Y, Li H (2007) Mechanism for effect of ultrasound on polymer melt in extrusion. J Polym Sci B Polym Phys 45(10):1226–1233. https://doi.org/10.1002/polb.21132

Isayev AI, Kumar R, Lewis TM (2009) Ultrasound assisted twin screw extrusion of polymer–nanocomposites containing carbon nanotubes. Polymer (Guildf) 50(1):250–260. https://doi.org/10.1016/j.polymer.2008.10.052

Mata-Padilla JM et al (2015) Structural and morphological studies on the deformation behavior of polypropylene/multi-walled carbon nanotubes nanocomposites prepared through ultrasound-assisted melt extrusion process. J Polym Sci B Polym Phys 53(7):475–491. https://doi.org/10.1002/polb.23655

Kim KY, Ju DU, Nam GJ, Lee JW (2007) Ultrasonic Effects on PP/PS/Clay Nanocomposites during Continuous Melt Compounding Process. Macromol Symp 249–250(1):283–288. https://doi.org/10.1002/masy.200750346

Andrade-Guel M et al (2021) Non-Woven Fabrics Based on Nanocomposite Nylon 6/ZnO Obtained by Ultrasound-Assisted Extrusion for Improved Antimicrobial and Adsorption Methylene Blue Dye Properties. Polymers (Basel) 13(11):1888. https://doi.org/10.3390/polym13111888

Swain SK, Isayev AI (2007) Effect of ultrasound on HDPE/clay nanocomposites: Rheology, structure and properties. Polymer (Guildf) 48(1):281–289. https://doi.org/10.1016/j.polymer.2006.11.002

Pérez-Medina J et al (2016) Metamaterial Behavior of Polymer Nanocomposites Based on Polypropylene/Multi-Walled Carbon Nanotubes Fabricated by Means of Ultrasound-Assisted Extrusion. Materials 9(11):923. https://doi.org/10.3390/ma9110923

Wang J et al (2021) Preparation of flexible and elastic thermal conductive nanocomposites via ultrasonic-assisted forced infiltration. Compos Sci Technol 202. https://doi.org/10.1016/j.compscitech.2020.108582

Li C et al (2022) Ultrasonic-Assisted Method for the Preparation of Carbon Nanotube-Graphene/Polydimethylsiloxane Composites with Integrated Thermal Conductivity Electromagnetic Interference Shielding, and Mechanical Performances. Int J Mol Sci 23(23):15007. https://doi.org/10.3390/ijms232315007

Zhao Y et al (2018) Ultrasonic processing of MWCNT nanopaper reinforced polymeric nanocomposites. Polymer (Guildf) 156:85–94. https://doi.org/10.1016/j.polymer.2018.09.053

Asif S, Chansoria P, Shirwaiker R (2020) Ultrasound-assisted vat photopolymerization 3D printing of preferentially organized carbon fiber reinforced polymer composites. J Manuf Process 56:1340–1343. https://doi.org/10.1016/j.jmapro.2020.04.029

Huang Y, Leu MC, Mazumder J, Donmez A (2015) Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations.J Manuf Sci Eng 137(1). https://doi.org/10.1115/1.4028725

Chockalingam K, Jawahar N, Chandrasekhar U (2006) Influence of layer thickness on mechanical properties in stereolithography. Rapid Prototyp J 12(2):106–113. https://doi.org/10.1108/13552540610652456

Chockalingam K, Jawahar N, Ramanathan KN, Banerjee PS (2006) Optimization of stereolithography process parameters for part strength using design of experiments. Int J Adv Manuf Technol 29(1–2):79–88. https://doi.org/10.1007/s00170-004-2307-0

Xue J, Wu T, Dai Y, Xia Y (2019) Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem Rev 119(8):5298–5415. https://doi.org/10.1021/acs.chemrev.8b00593

Mandzy N, Grulke E, Druffel T (2005) Breakage of TiO2 agglomerates in electrostatically stabilized aqueous dispersions. Powder Technol 160(2):121–126. https://doi.org/10.1016/j.powtec.2005.08.020

Wong CW et al (2020) Response Surface Methodology Optimization of Mono-dispersed MgO Nanoparticles Fabricated by Ultrasonic-Assisted Sol-Gel Method for Outstanding Antimicrobial and Antibiofilm Activities. J Clust Sci 31(2):367–389. https://doi.org/10.1007/s10876-019-01651-3

Srivatsan TS, Ibrahim IA, Mohamed FA, Lavernia EJ (1991) Processing techniques for particulate-reinforced metal aluminium matrix composites. J Mater Sci 26(22):5965–5978. https://doi.org/10.1007/BF01113872

Zhu L et al (2022) PVP/Highly Dispersed AgNPs Nanofibers Using Ultrasonic-Assisted Electrospinning. Polymers (Basel) 14(3):599. https://doi.org/10.3390/polym14030599

Dong Q et al (2013) Ultrasound-assisted preparation of electrospun carbon nanofiber/graphene composite electrode for supercapacitors. J Power Sources 243:350–353. https://doi.org/10.1016/j.jpowsour.2013.06.060

Hulsey S, Absar S, Choi H (2018) Investigation of simultaneous ultrasonic processing of polymer-nanoparticle solutions for electrospinning of nanocomposite nanofibers. J Manuf Process 34:776–784. https://doi.org/10.1016/j.jmapro.2018.03.050

Mulky E, Yazgan G, Maniura-Weber K, Luginbuehl R, Fortunato G, Bühlmann-Popa A-M (2014) Fabrication of biopolymer-based staple electrospun fibres for nanocomposite applications by particle-assisted low temperature ultrasonication. Mater Sci Eng C 45:277–286. https://doi.org/10.1016/j.msec.2014.09.009

Nonato RC, Mei LHI, Bonse BC, Chinaglia EF, Morales AR (2019) Nanocomposites of PLA containing ZnO nanofibers made by solvent cast 3D printing: Production and characterization. Eur Polym J 114:271–278. https://doi.org/10.1016/j.eurpolymj.2019.02.026

Kharissova OV, Torres-Martínez LM, Kharisov BI, editors (2021) Handbook of nanomaterials and nanocomposites for energy and environmental applications. Springer International Publishing. https://doi.org/10.1007/978-3-030-36268-3

Lu KL, Lago RM, Chen YK, Green MLH, Harris PJF, Tsang SC (1996) Mechanical damage of carbon nanotubes by ultrasound. Carbon N Y 34(6):814–816. https://doi.org/10.1016/0008-6223(96)89470-X

Englert M, Bittmann B, Haupert F, Schlarb AK (2012) Scaling-up of the dispersion process of nanoparticle-agglomerates in epoxy resin with an innovative continuous ultrasonic flow-through-cell dispersion system. Polym Eng Sci 52(1):102–107. https://doi.org/10.1002/pen.22051

Hu C et al (2017) Comparative assessment of the strain-sensing behaviors of polylactic acid nanocomposites: reduced graphene oxide or carbon nanotubes. J Mater Chem C Mater 5(9):2318–2328. https://doi.org/10.1039/C6TC05261D

Postiglione G, Natale G, Griffini G, Levi M, Turri S (2015) Conductive 3D microstructures by direct 3D printing of polymer/carbon nanotube nanocomposites via liquid deposition modeling. Compos Part A Appl Sci Manuf 76:110–114. https://doi.org/10.1016/j.compositesa.2015.05.014

Zhou YX, Wu PX, Cheng Z-Y, Ingram J, Jeelani S (2008) Improvement in electrical, thermal and mechanical properties of epoxy by filling carbon nanotube. Express Polym Lett 2(1):40–48. https://doi.org/10.3144/expresspolymlett.2008.6

Rezazadeh V, Pourhossaini MR, Salimi A (2017) Effect of amine-functionalized dispersant on cure and electrical properties of carbon nanotube/epoxy nanocomposites. Prog Org Coat 111:389–394. https://doi.org/10.1016/j.porgcoat.2017.06.017

Yang Y, Gupta MC, Zalameda JN, Winfree WP (2008) Dispersion behaviour, thermal and electrical conductivities of carbon nanotube-polystyrene nanocomposites. Micro Nano Lett 3(2):35. https://doi.org/10.1049/mnl:20070073

Pradhan AK, Swain SK (2012) Oxygen Barrier of Multiwalled Carbon Nanotube/Polymethyl Methacrylate Nanocomposites Prepared by in situ Method. J Mater Sci Technol 28(5):391–395. https://doi.org/10.1016/S1005-0302(12)60073-5

Abbasian M, Khayyatalimohammadi M (2023) Ultrasound-assisted synthesis of MIL-88(Fe) conjugated starch-Fe3O4 nanocomposite: A safe antibacterial carrier for controlled release of tetracycline. Int J Biol Macromol 123665. https://doi.org/10.1016/j.ijbiomac.2023.123665

Taka ZI, Mustafa MK, Sekak KA, Asman S (2019) Ultrasonic Assisted Preparation and Characterization of Conductive Polyaniline-Modified Magnetite Nanocomposites (PAni/Fe3O4 Nanocomposites)

Sharif A, Mustaqeem M, Saleh TA, ur Rehman A, Ahmad M, Warsi MF (2022) Synthesis, structural and dielectric properties of Mg/Zn ferrites -PVA nanocomposites. Mater Sci Eng B280:115689. https://doi.org/10.1016/j.mseb.2022.115689.

Ballarin B et al (2019) PANI/Au/Fe3O4 nanocomposite materials for high performance energy storage. Electrochim Acta 322. https://doi.org/10.1016/j.electacta.2019.134707

Rotaru R et al (2018) Ferromagnetic iron oxide–cellulose nanocomposites prepared by ultrasonication. Polym Chem 9(7):860–868. https://doi.org/10.1039/C7PY01587A

Saravanan A, Ramasamy RP (2016) Chitosan-maghemite-LiClO4 – a new green conducting superpara magnetic nanocomposite. J Polym Res 23(9):174. https://doi.org/10.1007/s10965-016-1072-8

Seo WJ et al (2006) Effects of ultrasound on the synthesis and properties of polyurethane foam/clay nanocomposites. J Appl Polym Sci 102(4):3764–3773. https://doi.org/10.1002/app.24735

Hyun YH, Lim ST, Choi HJ, Jhon MS (2001) Rheology of Poly(ethylene oxide)/Organoclay Nanocomposites. Macromolecules 34(23):8084–8093. https://doi.org/10.1021/ma002191w

Lim SK, Kim JW, Chin I-J, Choi HJ (2002) Rheological properties of a new rubbery nanocomposite: Polyepichlorohydrin/organoclay nanocomposites. J Appl Polym Sci 86(14):3735–3739. https://doi.org/10.1002/app.11451

Li J, Zhao L, Guo S (2005) Ultrasonic Preparation of Polymer/Layered Silicate Nanocomposites during Extrusion. Polym Bull 55(3):217–223. https://doi.org/10.1007/s00289-005-0424-z

Boro U, Kashyap N, Moholkar VS (2022) Sonochemical Synthesis of Poly(lactic acid) Nanocomposites with ZnO Nanoflowers: Effect of Nanofiller Morphology on Physical Properties. ACS Engineering Au 2(1):46–60. https://doi.org/10.1021/acsengineeringau.1c00018

Orasugh JT et al (2018) Jute cellulose nano-fibrils/hydroxypropylmethylcellulose nanocomposite: A novel material with potential for application in packaging and transdermal drug delivery system. Ind Crops Prod 112:633–643. https://doi.org/10.1016/j.indcrop.2017.12.069

Torgbo S, Sukyai P (2019) Fabrication of microporous bacterial cellulose embedded with magnetite and hydroxyapatite nanocomposite scaffold for bone tissue engineering. Mater Chem Phys 237. https://doi.org/10.1016/j.matchemphys.2019.121868

Abbasi AR, Morsali A (2010) Synthesis and Characterization of AgBr–Silk Nanocomposite Under Ultrasound Irradiation. J Inorg Organomet Polym Mater 20(4):825–832. https://doi.org/10.1007/s10904-010-9408-z

Sharififard H, Shahraki ZH, Rezvanpanah E, Rad SH (2018) A novel natural chitosan/activated carbon/iron bio-nanocomposite: Sonochemical synthesis, characterization, and application for cadmium removal in batch and continuous adsorption process. Bioresour Technol 270:562–569. https://doi.org/10.1016/j.biortech.2018.09.094

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflicts of interest and have not received any external funding for this research. We gratefully acknowledge the Department of Chemical Engineering, National Institute of Technology, Karnataka for providing the necessary facilities.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Soman, V., Vishwakarma, K. & Poddar, M.K. Ultrasound assisted synthesis of polymer nanocomposites: a review. J Polym Res 30, 406 (2023). https://doi.org/10.1007/s10965-023-03786-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03786-4