Abstract

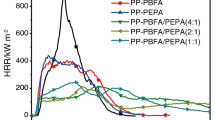

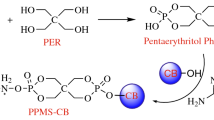

Aiming at developing a non-antimony synergistic agent of BFR and improving the high heat and smoke release of BFR due to its gaseous phase flame retardant mechanism, CeHPP was synthesized through hydrothermal reflux method and introduced into PC/DBDPO through melt blending. The morphology, chemical structure and thermal stability of CeHPP were characterized through SEM, FTIT and TG analysis, while the flame retardancy of PC/DBDPO/Sb2O3 and PC/DBDPO/CeHPP composites were compared and discussed in detail. To our delight, CeHPP showed more excellent synergistic effect with DBDPO than Sb2O3 in PC matrix. For PC/DBDPO/CeHPP (92/7/1, wt%), the sample was not ignited, the value of limited oxygen index (LOI) went up to 39.2% and it reached UL 94 V0 rating in vertical burning test, while the Izod impact strength, elongation at break and Young’s modulus were almost kept same with those of pure PC. Moreover, according to the cone calorimetry, CeHPP and DBDPO/CeHPP could efficiently suppress the heat and smoke release of PC composites, while DBDPO and DBDPO/Sb2O3 would accelerate the heat and smoke release during combustion The synergistic flame retardant mechanism verified that the char-barrier effect of CeHPP transferred the free-radical-trapping effect of BFRs from the gaseous phase to the condensed phase, which interfered the chain oxidation reaction of free-radicals and inhibiting the release and spread of gases and smoke.

Similar content being viewed by others

References

Barontini F, Marsanich K, Cozzani V (2004) J Therm Anal Calorim 78:599

Salmeia KA, Fage J, Liang SY, Gaan S (2015) Polymers 7:504

Wang MY, Horrocks AR, Horrocks S, Hall ME, Pearson JS, Clegg AS (2000) Journal of Fire Science 18:265

Howell BA, Cho YJ (2006) J Therm Anal Calorim 85:73

Shi XH, Li XL, Li YM, Li Z, Wang DY (2022) Composites Part B-Engineering 233:109663

Brandsma SH, Leonards PEG, Koekkoek JC, Samsonek J, Puype F (2022) Chemosphere 294:133774

Okeke ES, Huang B, Mao GH, Chen Y, Zeng ZJ, Qian X, Wu XY, Feng WW (2022) Environ Res 206:112594

Krenev VA, Dergacheva NP, Fomichev SV (2015) Theor Found Chem Eng 49:769

Henckens MLCM, Driessen PPJ, Worrell E (2016) Resour Conserv Recycl 108:54

Melanova K, Benes L, Svoboda J, Zima V, Pospisil M, Kovar P (2018) Dalton Trans 47:2867

Wilke M, Akhmetova I, Rademann K, Emmerling F (2018) J Mater Sci 53:13733

Sai T, Ran SY, Guo ZH, Yan HQ, Zhang Y, Song PG, Zhang T, Wang H, Fang ZP (2020) Composites Part B-Engineering 197:108064

Ran SY, Ye RF, Cai YF, Shen HY, He Y, Fang ZP, Guo ZH (2019) Polym Compos 40:986

Chen C, Guo ZH, Ran SY, Fang ZP (2014) Polym Compos 35:539

Cai YZ, Guo ZH, Fang ZP, Cao ZH (2013) Appl Clay Sci 77–78:10

Pan Y, Cai W, Du J, Song L, Hu Y, Zhao HT (2020) Polym Adv Technol 31:1330

Ran SY, Guo ZH, Chen C, Zhao LP, Fang ZP (2014) J Mater Chem A 2:2999

Guo ZH, Ran SY, Fang ZP (2017) J Therm Anal Calorim 128(3):1719

Saraci F, Quezada-Novoa V, Donnarumma PR, Howarth AJ (2020) Chem Soc Rev 49:7949

Cheisson T, Schelter EJ (2019) Science 363:489

Balaram V (2019) Geosci Front 10:1285

Pan YT, Zhang ZD, Yang RJ (2020) Composites Part B-Engineering 199:108265

Hou YB, Xu ZM, Chu FK, Gui Z, Song L, Hu Y, Hu WZ (2021) Composites Part B-Engineering 221:109014

Quan YF, Zhang ZR, Tanchak RN, Wang QS (2022) J Therm Anal Calorim 147:10209

Polli H, Pontes LAM, Souza MJB, Fernandes VJ, Araujo AS (2006) J Therm Anal Calorim 86:469

Erickson KL (2007) J Therm Anal Calorim 89:427

Davis A, Golden JH (1968) J Chem Soc B-Phys Organ 0:45

Yan L, Xu ZS, Deng N, Chu ZY (2019) J Therm Anal Calorim 138:915

Alonso A, Puente E, Lazaro P, Lazaro D, Alvear D (2017) J Therm Anal Calorim 129:639

Acknowledgements

This work was supported by the Zhejiang Province Public Welfare Technology Application Research Project (LGG21E030004), the National Natural Science Foundation of China (51991355, 52173082), the Ningbo Major Special Projects of Science and Technology Innovation 2025 (2020Z052) and the Ningbo Natural Science Foundation (2021J149, 2021J155).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with this work.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, B., Ye, R., Guo, Z. et al. Thermal stability and fire safety of polycarbonate flame retarded by the brominated flame retardant and a non-antimony synergistic agent. J Polym Res 30, 240 (2023). https://doi.org/10.1007/s10965-023-03586-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03586-w