Abstract

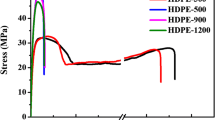

In this study, the performance mechanism of a new esterified PEG and a fluoropolymer as two different polymer processing aids (PPAs) on the HDPE was investigated. Die pressure of HDPE with introducing 1000 ppm of PPAs was conducted using the extrusion process. Our findings showed that PEG-based PPA decreased the primary pressure of HDPE from the start of the process while fluoropolymers after an induction time of around 6 min affect the HDPE die pressure. Time sweep tests were performed at two constants angular frequencies of 100 and 625 s− 1. During experiment time, the HDPE behavior was significantly influenced at high frequency for all samples including PPAs; whereas it was constant for HDPE. The study of the complex viscosity and dynamic modulus revealed that PEG-based PPA and fluoropolymer did not affect at low frequency. The rheological behavior of HDPE was altered as frequency increased from 100 to 625 s− 1.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available in our previous article https://doi.org/10.1063/5.0053461.

References

Wagner MH, Himmel T, Kulikov O, Hornung K (2014) Mechanisms of shark skin suppression by novel polymer processing aids. Mechanisms of Shark Skin Suppression by Novel Polymer Processing Aids, 96. https://doi.org/10.1063/1.4873742

Agassant JF, Arda DR, Combeaud C, Merten A, Münstedt H, Mackley MR, Robert L, Vergnes B (2006) Polymer processing extrusion instabilities and methods for their elimination or minimisation. Int Polym Process 21:239–255. https://doi.org/10.3139/217.0084

Vergnes B (2015) Extrusion defects and flow instabilities of molten polymers, 3–28. https://doi.org/10.3139/217.3011

Ansari M, Hatzikiriakos SG (2013) Wall Slip of Linear Polymers (HDPEs), 3. https://doi.org/10.1063/1.4802599

Migler KB, Lavallée C, Dillon MP, Woods SS, Gettinger CL (2011) Visualizing the elimination of sharkskin through fluoropolymer additives: Coating and polymer – polymer slippage. Published by the The Society of Rheology Visualizing the elimination of sharkskin through fluoropolymer additives : Coating and polymer – pol, 565. https://doi.org/10.1122/1.1349136

Achilleos EC, Georgiou G, Hatzikiriakos SG, Main M (2002) Role of processing aids in the extrusion of molten. Polymers, 7–24. https://doi.org/10.1002/vnl.10340

Hatzikiriakos SG (2012) Progress in polymer science wall slip of molten polymers. Prog Polym Sci 37:624–643. https://doi.org/10.1016/j.progpolymsci.2011.09.004

Müller M, Kulikov O, Hornung K, Wagner MH (2010) The use of thermoplastic elastomers as polymer processing aids in processing of linear low density polyethylene. 1, 2, 52:1163–1170. https://doi.org/10.1134/S0965545X10110106

Ansari M, Hatzikiriakos SG, Sukhadia AM, Rohlfing DC (2012) Melt fracture of two broad molecular weight distribution high-density polyethylenes. https://doi.org/10.1002/pen

Anastasiadis SH, Hatzikiriakos SG (2008) The work of adhesion of polymer / wall interfaces and its association with the onset of wall slip, 795. https://doi.org/10.1122/1.550909

Rosenbaum EE, Stuart K, Hatzikiriakos SG, Stewart CW, Henry M, Buckmaster EID, De Nemours C (2000) Im of polyolefins and fluoropolymers, 40. https://doi.org/10.1002/pen.11151

Kharchenko SB, Mcguiggan PM, Migler KB (2003) Flow induced coating of fluoropolymer additives: Development of frustrated total internal reflection imaging, 1523. https://doi.org/10.1122/1.1619375

Vergnes B (2011) Influence of die surface on the efficiency of fluoropolymer processing aids during the extrusion of linear-low density polyethylene. J Nonnewton Fluid Mech 166:847–858. https://doi.org/10.1016/j.jnnfm.2011.05.002

Vergnes B (2014) Fluoropolymer processing aids in linear-low density polyethylene extrusion: how to improve their efficiency? J Nonnewton Fluid Mech, 208–209. https://doi.org/10.1016/j.jnnfm.2014.04.002

Kulikov O, Hornung K, Wagner M (2007) Silanols cured by borates as lubricants in extrusion of LLDPE. Impact of elasticity of the lubricant on sliding friction, 741–754. https://doi.org/10.1007/s00397-007-0171-1

Kulikov O, Hornung K, Wagner MH (2010) Processing additives based on polyols and silanols for extrusion of polyolefins. Proceedings of the Polymer Processing Society 24th Annual Meeting ~ PPS-24 ~ June 15-19, 2008 Salerno (Italy)

Kulikov OL, Hornung K, Wagner MH, Kulikov OL, Hornung K, Wagner MH (2013) Impact of elasticity on lubrication. Esters of PEG, silanol and their blends as polymer processing additives, 63. https://doi.org/10.1063/1.2964792

Vinyl JOF, Technology A (2000) Effect of combining boron nitride with fluoroelastomer on the melt fracture of HDPE in extrusion blow molding, 6. https://doi.org/10.1002/vnl.10253

Kazatchkov IB (2000) The effect of boron nitride on the rheology and processing of polyole ® ns, 583–594. https://doi.org/10.1007/s003970000113

Damianou Y, Philippou M, Kaoullas G, Georgiou GC (2014) Cessation of viscoplastic poiseuille flow with wall slip. J Nonnewton Fluid Mech 203:24–37. https://doi.org/10.1016/j.jnnfm.2013.10.004

Sabzevari SM, Cohen I, Wood-adams PM (2014). Wall slip of bidisperse linear polymer melts. https://doi.org/10.1021/ma500451g

Rodríguez-gonzález F, Pérez-gonzález J, Marín-santibáñez BM, De Vargas L (2009) Kinematics of the stick – slip capillary flow of high-density polyethylene. Chem Eng Sci 64:4675–4683. https://doi.org/10.1016/j.ces.2009.02.033

Ren Z, Huang X, Liu H (2017) Wall slip velocity measurement of molten polypropylene in capillary flow based on length-corrected Mooney technique, 445891–14. https://doi.org/10.1002/app.44589

Bigio D, Meillon MG, Kharchenko SB, Morgan D, Zhou H, Oriani SR, Macosko CW, Migler KB, Elastomers D (2005) Coating kinetics of fluoropolymer processing aids for sharkskin elimination: The role of droplet size, 13122–31. https://doi.org/10.1016/j.jnnfm.2005.04.008

Vergnes B (2011) Multi-scale phenomena induced by fluoropolymer processing aids during the extrusion of linear-low density polyethylene. J Nonnewton Fluid Mech 166:1–11. https://doi.org/10.1016/j.jnnfm.2010.09.008

Kissi NE (1995) Distortions of polymer melt extrudates and their elimination using slippery surfaces, 5740–57. https://doi.org/10.1007/BF00396053

Zhang W, Deodhar S, Yao D (2010) Processing properties of polypropylene with a minor addition of silicone oil. https://doi.org/10.1002/pen

Devaux N, Vergnes B (2008) Influence of the nature of fluoropolymer processing aids on the elimination of sharkskin defect in LLDPE extrusion, 727–730. https://doi.org/10.1007/s12289-008-0

Gang H, Cuculo JA, Nam S, Crater DH (1995) Frictional properties of polyolefins treated with fluoroelastomer processing aids. https://doi.org/10.1002/app.1995.070551011

Tian J, Yu W, Zhou C (2006) The preparation and rheology characterization of long chain branching polypropylene, 477962–7969. https://doi.org/10.1016/j.polymer.2006.09.042

Doi M, Edwards SF (n.d.) The theory of polymer dynamics. Oxford University Press, New York, 1986, 218–283. https://doi.org/10.1002/pol.1989.140270706

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We confirm that the manuscript has been read and approved by all named authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dehghani, S. Mechanism of the esterified processing aid based on PEG and fluoropolymers in molten high-density polyethylene (HDPE). J Polym Res 30, 153 (2023). https://doi.org/10.1007/s10965-023-03529-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03529-5