Abstract

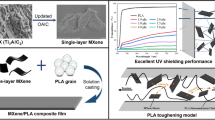

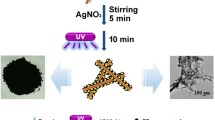

Conductive polymer composites (CPCs) with segregated networks are highly desirable for lowering the percolation threshold as well as the synergetic upgrading of electrical and thermal properties. Here we disclose a one-pot water mediated process for developing conductive composite of poly(methyl methacrylate) (PMMA) with dense poly(3,4-ethylenedioxythiophene) (PEDOT) surface as segregated conductive channel. The key idea is the judicious handling of surface charges of PMMA latex and 3,4-ethylenedioxythiophene (EDOT) emulsion which are prepared using surfactant free emulsion polymerization and acoustic emulsification, respectively. The obtained composite shows refinement in material properties as compared to the composites prepared using conventional methods. The composite provides about ~105 and ~107 fold increase in electrical conductivity as compared to the composites prepared by the direct addition of EDOT to the PMMA latex and physical blending of PMMA with PEDOT bulk particles, respectively. Additionally it shows ~ 1011 fold increase in electrical conductivity compared with the PMMA matrix. This method opens up a new path in sustainable materials research for the synthesis of conductive polymer composites.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article (and its supplementary information files).

References

Chen J, Liao X, Xiao W et al (2019) Facile and green method to structure ultralow-threshold and lightweight Polystyrene/MWCNT composites with segregated conductive networks for efficient electromagnetic interference shielding. ACS Sustain Chem Eng 7:9904–9915

Pang H, Xu L, Yan DX, Li ZM (2014) Conductive polymer composites with segregated structures. Prog Polym Sci 39:1908–1933

Wang M, Tang XH, Cai JH et al (2021) Construction, mechanism and prospective of conductive polymer composites with multiple interfaces for electromagnetic interference shielding: a review. Carbon 177:377–402

Bagotia N, Choudhary V, Sharma DK (2018) Superior electrical, mechanical and electromagnetic interference shielding properties of polycarbonate/ethylene-methyl acrylate-in situ reduced graphene oxide nanocomposites. J Mater Sci 53:16047–16061

Umoren SA, Solomon MM (2019) Protective polymeric films for industrial substrates: a critical review on past and recent applications with conducting polymers and polymer composites/nanocomposites. Prog Mater Sci 104:380–450

Jiang D, Murugadoss V, Wang Y et al (2019) Electromagnetic interference shielding polymers and nanocomposites - a review. Polym Rev 59:280–337

Jang BJ, Oh JH (2005) Fabrication of a highly transparent conductive thin film from polypyrrole / poly (methyl methacrylate) core / shell nanospheres. Adv Funct Mater 15:494–502

Pisuchpen T, Keaw-on N, Kitikulvarakorn K et al (2017) Electrospinning and solid state polymerization: a simple and versatile route to conducting PEDOT composite films. Eur Polym J 96:452–462

Hatchett DW, Josowicz M (2008) Composites of intrinsically conducting polymers as sensing nanomaterials. Chem Rev 108:746–769

Raman S, Ravi Sankar A (2022) Intrinsically conducting polymers in flexible and stretchable resistive strain sensors: a review. J Mater Sci 57:13152–13178

Laforgue A, Robitaille L (2010) Deposition of ultrathin coatings of polypyrrole and poly (3, 4-ethylenedioxythiophene) onto electrospun nanofibers using a vapor-phase polymerization method. Chem Mater 22:2474–2480

Kwon OS, Park SJ, Park HW et al (2012) Kinetically controlled formation of multidimensional poly(3,4-ethylenedioxythiophene) nanostructures in vapor-deposition polymerization. Chem Mater 24:4088–4092

Ghalib H, Abdullah I, Daik R (2013) Electrically conductive polystyrene/polypyrrole nanocomposites prepared via emulsion polymerization. Polym Plast Technol Eng 52:478–484

Park H, Jong S, Kim S et al (2013) Conducting polymer nanofiber mats via combination of electrospinning and oxidative polymerization. Polymer 54:4155–4160

Steen T, West K, Hassager O, Larsen NB (2006) Integration of conducting polymer network in non-conductive polymer substrates. Synth Met 156:1203–1207

Kayser LV, Lipomi DJ (2019) Stretchable conductive polymers and composites based on PEDOT and PEDOT:PSS. Adv Mater 31:1–13

Winther-Jensen B, West K (2004) Vapor-phase polymerization of 3,4-ethylenedioxythiophene: a route to highly conducting polymer surface layers. Macromolecules 37:4538–4543

Zozoulenko I, Franco-Gonzalez JF, Gueskine V et al (2021) Electronic, Optical, Morphological, Transport, and Electrochemical Properties of PEDOT: a theoretical perspective. Macromolecules 54:5915–5934

Kim J, Lee J, You J et al (2016) Conductive polymers for next-generation energy storage systems: recent progress and new functions. Mater Horiz 3:517–535

Rahimzadeh Z, Naghib SM, Zare Y, Rhee KY (2020) An overview on the synthesis and recent applications of conducting poly(3,4-ethylenedioxythiophene) (PEDOT) in industry and biomedicine. J Mater Sci 55:7575–7611

Leong TSH, Martin GJO, Ashokkumar M (2017) Ultrasonic encapsulation – a review. Ultrason Sonochem 35:605–614

Tzirakis MD, Zambail R, Tan YZ et al (2015) Surfactant-free synthesis of sub-100nm poly(styrene-co-divinylbenzene) nanoparticles by one-step ultrasonic assisted emulsification/polymerization. RSC Adv 5:103218–103228

Asami R, Atobe M, Fuchigami T (2005) Electropolymerization of an immiscible monomer in aqueous electrolytes using acoustic emulsification. J Am Chem Soc 127:13160–13161

Nakabayashi K, Yanagi H, Atobe M (2014) Preparation of W/O nanoemulsion using tandem acoustic emulsification and its novel utilization as a medium for phase-transfer catalytic reaction. RSC Adv 4:57608–57610

Asami R, Fuchigami T, Atobe M (2006) Development of a novel environmentally friendly electropolymerization of water-insoluble monomers in aqueous electrolytes using acoustic emulsification. Langmuir 22:10258–10263

Nakabayashi K, Kojima M, Inagi S et al (2013) Size-controlled synthesis of polymer nanoparticles with tandem acoustic emulsification followed by soap-free emulsion polymerization. ACS Macro Lett 2:482–484

Li MK, Fogler HS (1978) Acoustic emulsification. Part 1. The instability of the oil-water interface to form the initial droplets. J Fluid Mech 88:499–511

Li MK, Fogler HS (1978) Acoustic emulsification. Part 2. Breakup of the large primary oil droplets in a water medium. J Fluid Mech 88:513–528

Reddy SR, Fogler HS (1980) Emulsion stability of acoustically formed emulsions. J Phys Chem 84:1570–1575

Gross S, Camozzo D, Di Noto V et al (2007) PMMA: a key macromolecular component for dielectric low-κ hybrid inorganic-organic polymer films. Eur Polym J 43:673–696

Ali U, Karim KJBA, Buang NA (2015) A review of the Properties and Applications of Poly (Methyl Methacrylate) (PMMA). Polym Rev 55:678–705

Pham VH, Dang TT, Hur SH et al (2012) Highly conductive poly(methyl methacrylate) (PMMA)-reduced graphene oxide composite prepared by self-assembly of PMMA latex and graphene oxide through electrostatic interaction. ACS Appl Mater Interfaces 4:2630–2636

Camli ST, Buyukserin F, Balci O, Budak GG (2010) Size controlled synthesis of sub-100 nm monodisperse poly(methylmethacrylate) nanoparticles using surfactant-free emulsion polymerization. J Colloid Interface Sci 344:528–532

Sanchis MJ, Redondo-Foj B, Carsí M et al (2016) Controlling dielectrical properties of polymer blends through defined PEDOT nanostructures. RSC Adv 6:62024–62030

Master AM, Rodriguez ME, Kenney ME et al (2010) Delivery of the photosensitizer pc 4 in PEG–PCL micelles for in vitro PDT studies. J Pharm Sci 99:2386–2398

Zhao Q, Jamal R, Zhang L et al (2014) The structure and properties of PEDOT synthesized by template-free solution method. Nanoscale Res Lett 9:1–9

Bongo M, Winther-Jensen O, Himmelberger S et al (2013) PEDOT:gelatin composites mediate brain endothelial cell adhesion. J Mater Chem B 1:3860–3867

Saeed PA, Shilpa R, Athiyanathil S (2022) A water mediated approach for the preparation of conductive poly (3,4-ethylenedioxythiophene) decorated poly (methyl methacrylate) microcomposites. Mater Adv. https://doi.org/10.1039/d2ma00027j

Kim TY, Park CM, Kim JE, Suh KS (2005) Electronic, chemical and structural change induced by organic solvents in tosylate-doped poly(3,4-ethylenedioxythiophene) (PEDOT-OTs). Synth Met 149:169–174

Thakur VK, Vennerberg D, Madbouly SA, Kessler MR (2014) Bio-inspired green surface functionalization of PMMA for multifunctional capacitors. RSC Adv 4:6677–6684

Yilmaz E, Sezen H, Suzer S (2012) Probing the charge build-up and dissipation on thin PMMA Film Surfaces at the molecular level by XPS. Angew Chem 124:5584–5588

Nathawat R, Kumar A, Acharya NK, Vijay YK (2009) XPS and AFM surface study of PMMA irradiated by electron beam. Surf Coat Technol 203:2600–2604

Khan MA, Armes SP, Perruchot C et al (2000) Surface characterization of poly(3,4-ethylenedioxythiophene)-coated latexes by X-ray photoelectron spectroscopy. Langmuir 16:4171–4179

Mitraka E, Jafari MJ, Vagin M et al (2017) Oxygen-induced doping on reduced PEDOT. J Mater Chem A 5:4404–4412

Fabretto M, Zuber K, Hall C et al (2009) The role of water in the synthesis and performance of vapour phase polymerised PEDOT electrochromic devices. J Mater Chem 19:7871–7878

Khan MA, Armes SP (1999) Synthesis and characterization of micrometer-sized poly(3,4-ethylenedioxythiophene)-coated polystyrene latexes. Langmuir 15:3469–3475

Nair S, Hsiao E, Kim SH (2008) Fabrication of electrically-conducting nonwoven porous mats of polystyrene – polypyrrole core – shell nanofibers via electrospinning and vapor phase polymerization †. J Mater Chem 18:5155–5161

Nair S, Hsiao E, Kim SH (2009) Melt-welding and improved electrical conductivity of nonwoven porous nanofiber mats of poly(3,4-ethylenedioxythiophene) grown on electrospun polystyrene fiber template. Chem Mater 21:115–121

Choi JW, Han MG, Kim SY et al (2004) Poly(3,4-ethylenedioxythiophene) nanoparticles prepared in aqueous DBSA solutions. Synth Met 141:293–299

Acknowledgements

Not applicable.

Author information

Authors and Affiliations

Contributions

All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

10965_2023_3497_MOESM1_ESM.docx

Supplementary file1 (DOCX 439 KB) Zeta potential distributions of EDOT samples, EDX spectra of PMMA-PEDOT composites and table of the electrical conductivity of PMMA and different composites

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Saeed, P.A., Juraij, K., Saharuba, P.M. et al. A one-pot water mediated process for developing conductive composites with segregated network of poly(3,4-ethylenedioxythiophene) on spherical poly(methyl methacrylate) particles. J Polym Res 30, 116 (2023). https://doi.org/10.1007/s10965-023-03497-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03497-w