Abstract

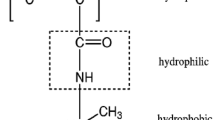

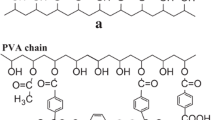

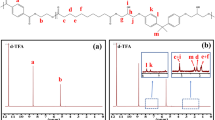

In this study, a new type of compatibilizer, benzamide-grafted polyethylene polyamine (PEPA) containing solvent chain (PDABA-g-PEPA-O) was prepared from PEPA, 3,5-diaminobenzoic acid (DABA) and Oleoyl chloride (OC) and used to modify sisal microcrystalline cellulose (MCC). The natural rubber (NR) was filled with the modified MCC to prepare composites. The compatibilization effect of the prepared compatibilizer on the NR/MCC/PEPA-g-PDABA-O composites was investigated and its compatibilization mechanism was analyzed by molecular dynamics simulation (MD). The results show that adding 3wt% (calculated by MCC mass) PDABA-g-PEPA-O can improve the interfacial interaction between NR and MCC. The highest tensile strength of the NR composites was 25.319 MPa when 2.5phr MCC and 3wt% of PDABA-g-PEPA-O were added and is improved by 13.07% compared with that of NR/2.5phr MCC composites. In addition, the MD results showed that the amide and amine groups in the molecular structure of PDABA-g-PEPA-O formed a strong hydrogen bond and a strong van der Waals interaction with the hydroxyl groups of cellulose and PDABA-g-PEPA-O exhibited good compatibility with NR, which achieved the purpose of compatibilization. Moreover, the properties of tensile, deformation and shear resistance of the composites were enhanced with the addition of PDABA-g-PEPA-O in molecular simulation. The MD results provided a basis for the molecular design and preparation of compatibilizers and understanding their compatibilization mechanism in the polymer composites at a molecular level.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are available from the corresponding author upon reasonable request.

References

Surajarusarn B, Thaiwattananon S, Thanawan S et al (2021) Realising the potential of pineapple leaf fiber as green and high-performance reinforcement for natural rubber composite with liquid functionalized rubber. Fiber Polym 22:2543–2551. https://doi.org/10.1007/s12221-021-1018-6

Chawalitsakunchai W, Dittanet P, Loykulnant S et al (2021) Properties of natural rubber reinforced with nano cellulose from pineapple leaf agricultural waste. Mater Today Commun 28:102594. https://doi.org/10.1016/j.mtcomm.2021.102594

Xu TW, Li K, Wang YQ et al (2019) Enhancing interfacial and mechanical properties of NR/montmorillonite composites using butadiene-styrene-vinylpyridine rubber as compatilizer. Mater Chem Phys 231:357–365. https://doi.org/10.1016/j.matchemphys.2019.04.005

Wongsorat W, Suppakarn N, Jarukumjorn K (2014) Effects of compatibilizer type and fiber loading on mechanical properties and cure characteristics of sisal fiber/natural rubber composites. J Compos Mater 48:2401–2411. https://doi.org/10.1177/0021998313498790

Singh MK, Zafar S, Rangappa SM et al (2022) Influence of microwave power and HDPE blend ratio on thermal and mechanical properties of kenaf reinforced PLLA/HDPE blended composites. J Polym Res 29:268. https://doi.org/10.1007/s10965-022-03120-4

Sui GP, Jing MF, Zhao J et al (2018) A comparison study of high shear force and compatibilizer on the phase morphologies and properties of polypropylene/polylactide (PP/PLA) blends. Polym 154:119–127. https://doi.org/10.1016/j.polymer.2018.09.005

Wang HK, Liu XR, Liu JF et al (2022) Tailoring interfacial adhesion between PBAT matrix and PTFE-modified microcrystalline cellulose additive for advanced composites. Polymers 14:1973. https://doi.org/10.3390/polym14101973

Hu XR, Li Y, Gao Y et al (2019) Renewable and super-toughened poly (butylene succinate) with bio-based elastomers: Preparation, compatibility and performances. Eur Polym J 116:438–444. https://doi.org/10.1016/j.eurpolymj.2019.03.057

Wan YL, Wu HJ, Huang LH et al (2018) Preparation and characterization of corn cob/polypropylene composite reinforced by wood ash. Polym Bull 75:2125–2138. https://doi.org/10.1007/s00289-017-2149-1

Ali MAM, El-Nemr KF, Badawy NA et al (2019) Thermal and physicomechanical properties of gamma-irradiated EPDM/waste newsprint microfibers composites treated using acrylic styrene emulsion as a coupling agent. J Vinyl Addit Techn 25:E91–E106. https://doi.org/10.1002/vnl.21648

Ponsuriyaprakash S, Udhayakumar P, Pandiyarajan R (2022) Experimental investigation of ABS matrix and cellulose fiber reinforced polymer composite materials. J Nat Fibers 19:3241–3252. https://doi.org/10.1080/15440478.2020.1841065

Thakur VK, Singha AS, Thakur MK (2012) Green composites from natural fibers: mechanical and chemical aging properties. Int J Polym Anal Ch 17:401–407. https://doi.org/10.1080/1023666X.2012.668665

Wu LY, Lu SR, Pan LL et al (2016) Enhanced thermal and mechanical properties of polypropylene composites with hyperbranched polyester grafted sisal microcrystalline. Fiber Polym 17:2153–2161. https://doi.org/10.1007/s12221-016-6257-6

Kellersztein I, Shani U, Zilber I et al (2019) Sustainable composites from agricultural waste: the use of steam explosion and surface modification to potentialize the use of wheat straw fibers for wood plastic composite industry. Polym Composite 40:E53–E61. https://doi.org/10.1002/pc.24472

Zhan JH, Wang GL, Li J et al (2021) Effect of the compatilizer and chemical treatments on the performance of poly(lactic acid)/ramie fiber composites. Compos Commun 27:100843. https://doi.org/10.1016/j.coco.2021.100843

Fortelny I, Juza J (2021) The effects of copolymer compatibilizers on the phase structure evolution in polymer blends-a review. MATERIALS 14:7786. https://doi.org/10.3390/ma14247786

Zhang HS, Guo WH, Yu YB et al (2007) Structure and properties of compatibilized recycled poly(ethylene terephthalate)/linear low density polyethylene blends. Eur Polym J 43:3662–3670. https://doi.org/10.1016/j.eurpolymj.2007.05.001

Aziz AA, Akil HM, Jamaludin SMS et al (2011) The effect of multiple compatibilizers on the impact properties of polypropylene/polystyrene (PP/PS) blend. Polym-Plast Technol 50:768–775. https://doi.org/10.1080/03602559.2010.551441

Spoljaric S, Genovese A, Shanks RA (2009) Polypropylene-microcrystalline cellulose composites with enhanced compatibility and properties. Compos Part A-Appl S 40:791–799. https://doi.org/10.1016/j.compositesa.2009.03.011

Niu PF, Liu BY, Wei XM et al (2011) Study on mechanical properties and thermal stability of polypropylene/hemp fiber composites. J Reinf Plast Comp 30:36–44. https://doi.org/10.1177/0731684410383067

Yang J, Lu SR, Luo QY et al (2018) Enhanced mechanical and thermal properties of polypropylene/cellulose fibers composites with modified tannic as a compatibilizer. Polym Composite 39:2036–2045. https://doi.org/10.1002/pc.24165

Zhang ZD, Liu YX, Chen X et al (2016) Multi-responsive polyethylene-polyamine/gelatin hydrogel induced by non-covalent interactions. RSC Adv 6:48661–48665. https://doi.org/10.1039/c6ra05764k

Wang BY, Lan JM, Pu JL et al (2021) (2021) Adsorption of cadmium ions from simulated battery waste water by polyethylene polyamine modified activated carbon. Water Sci Technol 84:3916–3927. https://doi.org/10.2166/wst.2021.488

Li J, Bai T (2011) The addition of polyethylene-polyamine surface treated carbon nanotube on the interfacial adhesion of carbon fiber-reinforced polyimide composite. Polym-Plast Technol 50:1393–1397. https://doi.org/10.1080/03602559.2011.593077

Yuan L, Wen TP, Jiang LY et al (2021) Modified superhydrophilic/underwater superoleophobic mullite fiber-based porous ceramic for oil-water separation. Mater Res Bull 143:111454. https://doi.org/10.1016/j.materresbull.2021.111454

Wang ZQ, Yang LL, Yang Q et al (2021) Dual functional alginate-polyethylene polyamine composite aerogel toward sensing and extracting copper ions in water. ChemistrySelect 6:1526–1532. https://doi.org/10.1002/slct.202004393

Zhuang QX, Xue ZJ, Liu XY et al (2011) Molecular simulation of miscibility of poly(2,6-dimethyl-1,4-phenylene ether)/poly(styrene-co-acrylonitrile) blend with the compatibilizer triblock terpolymer SBM. Polym Composite 32:1671–1680. https://doi.org/10.1002/pc.21203

Gu CH, Gu HY, Lang MD (2013) Molecular simulation to predict miscibility and phase separation behavior of chitosan/poly(epsilon-caprolactone) binary blends: a comparison with experiments. Macromol Theory Simul 22:377–384. https://doi.org/10.1002/mats.201300109

Wang WZ, Li LJ, Jin SH et al (2020) (2020) Study on cellulose acetate butyrate/plasticizer systems by molecular dynamics simulation and experimental characterization. Polymers 12:1272. https://doi.org/10.3390/polym12061272

Zhang MH, Jiang BY, Chen C et al (2019) The effect of temperature and strain rate on the interfacial behavior of glass fiber reinforced polypropylene composites: a molecular dynamics study. Polymers 11:1766. https://doi.org/10.3390/polym11111766

Deshpande PP, Radue MS, Gaikwad P et al (2021) Prediction of the interfacial properties of high-performance polymers and flattened CNT-reinforced composites using molecular dynamics. Langmuir 37:11526–11534. https://doi.org/10.1021/acs.langmuir.1c01800

Tang J, Wang H, Liang M (2022) Molecular simulation and experimental analysis of interaction and compatibility between asphalt binder and Styrene-Butadiene-Styrene. Constr Build Mater 342:128028. https://doi.org/10.1016/j.conbuildmat.2022.128028

Chen S, Li J, Wei L et al (2018) A molecular modeling study for miscibility of polyimide/polythene mixing systems with/without compatibilizer. J Polym Eng 38:891–898. https://doi.org/10.1515/polyeng-2017-0374

Li MM, Li FS, Shen RQ et al (2011) Molecular dynamics study of the structures and properties of RDX/GAP propellant. J Hazard Mater 186:2031–2036. https://doi.org/10.1016/j.jhazmat.2010.12.101

He LP, Li WJ, Chen DC et al (2018) Investigation on the microscopic mechanism of potassium permanganate modification and the properties of ramie fiber/polypropylene composites. Polym Composite 39:3353–3362. https://doi.org/10.1002/pc.24355

Xu XL, Zhang M, Wang L et al (2016) Comparative study on interaction of N-PBS and cellulose derivatives by dynamic simulation. Colloid Polym Sci 294:755–765. https://doi.org/10.1007/s00396-016-3833-7

Jing J, Qiao QA, Jin YQ et al (2012) Molecular and mesoscopic dynamics simulations on the compatibility of PLA/plasticizer blends. Chinese J Chem 30:133–138. https://doi.org/10.1002/cjoc.201180454

Wu YK, Ma JZ, Xu QN et al (2022) Improved strength and water vapor permeability of polyacrylate/SiO2 nanocomposites: molecular simulations and experimental analysis. Colloid Surf A. https://doi.org/10.1016/j.colsurfa.2021.128236

Wang LH, Tang C, Wang XB et al (2019) Molecular dynamics simulation on the thermodynamic properties of insulating paper cellulose modified by silane coupling agent grafted nano-SiO2. Aip Adv. https://doi.org/10.1063/1.5131821

Acknowledgements

The authors gratefully acknowledge the financial support of the Science and Technology Project of Guangxi (AB21220060), and the Guangxi Natural Science Youth Foundation (2021GXNSFBA220043), the Science and Technology Major Project of Guangxi (AA18242008) and the platform of Shenzhen Supercomputer Center which support the molecular dynamics simulation.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, D., Li, Z., Li, D. et al. Preparation of compatibilizer PDABA-g-PEPA-O and its application in NR/MCC composites and analysis of compatibilization mechanism. J Polym Res 30, 123 (2023). https://doi.org/10.1007/s10965-023-03490-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03490-3