Abstract

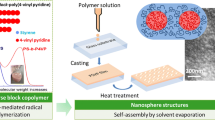

Phosphogypsum is industrial waste that wastes a lot of land and pollutes the environment. In recent years, the application of phosphogypsum in polymers has become one of the research hotspots. In this paper, phosphogypsum/polystyrene composite was prepared by pretreatment, organic modification, and then mixed with polystyrene solution. It was found that phosphogypsum crystals had a highly orientation arrangement after pre treatment. Phosphogypsum exists as single crystal in polystyrene. Phosphogypsum has good dispersion and good interfacial properties in the polymerization. It provides guidance and reference for the application of phosphogypsum in polymer.

Similar content being viewed by others

References

Haidar M, Ghorbel E, Toutanji H (2011) Optimization of the formulation of micro-polymer concretes. Construct Build Mater 25(4):1632–1644

Jafari K, Tabatabaeian M, Joshaghani A, Ozbakkaloglu T (2018) Optimizing the mixture design of polymer concrete: An experimental investigation. Construct Build Mater 167:185–196

Hassani Niaki M, Fereidoon A, Ghorbanzadeh Ahangari M (2018) Experimental study on the mechanical and thermal properties of basalt fiber and nanoclay reinforced polymer concrete. Compos Struct 191:231–238

Şimşek B, Uygunoğlu T (2017) A full factorial-based desirability function approach to investigate optimal mixture ratio of polymer concrete. Polym Compos 24330:3199–3211

Verbeek CJR, du Plessis BJGW (2005) Density and flexural strength of phosphogypsum–polymer composites. Construct Build Mater 19(4):265–274

Essabir H, Nekhlaoui S, Bensalah MO, Rodrigue D, Bouhfid R, Qaiss AEK (2016) Phosphogypsum Waste Used as Reinforcing Fillers in Polypropylene Based Composites: Structural, Mechanical and Thermal Properties. J Polym Environ 25(3):658–666

Szajerski P, Bogobowicz A, Bem H, Gasiorowski A (2019) Quantitative evaluation and leaching behavior of cobalt immobilized in sulfur polymer concrete composites based on lignite fly ash, slag and phosphogypsum. J Clean Product 222:90–102

Laurino JP, Mustacato J, Huba ZJ (2019) Rare Earth Element Recovery from Acidic Extracts of Florida Phosphate Mining Materials Using Chelating Polymer 1-Octadecene, Polymer with 2,5-Furandione, Sodium Salt. Minerals 9(8):477, 1–10

Dai Q, Ma L, Ren N, Ning P, Guo Z, Xie L, Gao H (2018) Investigation on extracellular polymeric substances, sludge flocs morphology, bound water release and dewatering performance of sewage sludge under pretreatment with modified phosphogypsum. Water Res 142:337–346

Zhu Y-J (2017) Nanostructured Materials of Calcium Phosphates and Calcium Silicates: Synthesis. Properties and Applications. Chinese J Chem 35(6):769–790

Bensalah H, Bekheet MF, Alami Younssi S, Ouammou M, Gurlo A (2018) Hydrothermal synthesis of nanocrystalline hydroxyapatite from phosphogypsum waste. J Environ Chem Eng 6(1):1347–1352

Ibrahim M, Labaki M, Giraudon JM, Lamonier JF (2020) Hydroxyapatite, a multifunctional material for air, water and soil pollution control: A review. J Hazard Mater 383, 121139, 1–18

Li X, Zhang Q, Shen Z, Li L, Li X, Mao S (2019) A crystal modifier for preparation of hemihydrate from phosphogypsum in CaCl2 solution. J Cryst Growth 511:48–55

Banfield JF, Welch SA, Zhang H, Ebert TT, Penn RL (2000) Aggregation-Based Crystal Growth and Microstructure Development in Natural Iron Oxyhydroxide Biomineralization Products. Science 289:751–754

De Yoreo JJ, Gilbert PU, Sommerdijk NA, Penn RL, Whitelam S, Joester D, Zhang H, Rimer JD, Navrotsky A, Banfield JF, Wallace AF, Michel FM, Meldrum FC, Colfen H, Dove PM (2015) Crystallization by particle attachment in synthetic, biogenic, and geologic environments. Science 349(6247):6760, 1–9

Cao K, Zhou Y, Liu G, Wang H, Sun W (2014) Preparation and properties of a polyether-based polycarboxylate as an antiscalant for gypsum. J Appl Polym Sci 20193:1–9

Qijie W Principle and technology of crystal growth. Science press. 2nd. 2018.06 (in Chinese)

Cao F, Zheng H, Jia S, Bai X, Li L, Sheng H, Wu S, Han W, Li M, Wen G, Yu J, Wang J (2015) Atomistic Observation of Phase Transitions in Calcium Sulfates under Electron Irradiation. The J Phys Chem C 119(38):22244–22248

Kamarou M, Kuzmenkov M, Korob N, Kwapinski W, Romanovski V (2020) Structurally controlled synthesis of calcium sulphate dihydrate from industrial wastes of spent sulphuric acid and limestone. Environ Technol Innov 17(100582):1–8

Ma L, Yang A, Liu Y, Mao H, Hua Su, Jiu S, Wang X (2015) Characterization and analysis of TG and DSC on the thermal dehydration of phosphogypsum and pure gypsum. Applied Chemical Industry 44(5):959–962. (in Chinese)

Hudson-Lamb DL (1996) The thermal dehydration of natural gypsum and pure calcium sulphate dihydrate (gypsum). Thermochem Acta (282 /283):483–492

Acknowledgements

This work was supported by the engineering Research Center of Comprehensive Utilization of Phosphogypsum in Colleges and Universities of Guizhou Province (Guizhou Jiaohe KY zi [2018]010), Qiannan Science and Technology Bureau Phosphorus Chemical Industry Technology Roadmap (Qiannan Kehe (2018) No. 01), Study on the modification of phosphogypsum by styrene ATRP and the application of key technologies in foamed concrete (Qiannan Kehe Yizhi (2017) No.8), the Science and Technology Support Plan Project of Guizhou Province (Grant [2020]4Y041), the Basic Research Plan of Guizhou Province (Grant [2019]1135), and the Natural science research project of Guizhou Education Department in 2020 (Qian jiaohe KY Zi [2021]052).

Author information

Authors and Affiliations

Contributions

Jie Zhang, Jingyu Ran and Xiangdong Su conceived the idea and designed the experiments. Xiangdong Su supervised the project. Jie Zhang, Han Lu, Dan Zeng, Dongye Meng, Jiajun Chen, Kun Liu, Jingyu Ran carried out the synthetic experiment and analysis. Jie Zhang, Jingyu Ran and Xiangdong Su wrote the paper, and all authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, J., Lu, H., Zeng, D. et al. Highly oriented arrangement of phosphogypsum crystals and structure of phosphogypsum/Polystyrene composites. J Polym Res 29, 461 (2022). https://doi.org/10.1007/s10965-022-03143-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03143-x