Abstract

Using polyurethane foams integrated with phase change materials (PCMs) that take cooperative advantages of heat insulation and heat storage capacity can meet the demand for thermal comfort and energy conservation purpose in the buildings. One-shot synthesis method, a cost-effective method, was used in this study for fabrication of PU-PCM composite foams. It is ascertained that thermal regulation capacity of composite foams is facilely tunable as latent heat storage properties of composite foams containing 10–20 wt.% n-octadecane as PCM ranged from 17.72 J.g−1 to 34.51 J.g−1. Inclusion of PCM resulted in increasing the cell size of composite foams accompanied with reduced closed-cell content compared with those of pristine PU foam. However, as the PCM fraction increased, the cell size of composite foams tended to decrease. Given the fact that the geometry of foam cells determines specific compressive properties, specific compressive strength and modulus of PU foam dropped from 3.89 ± 0.20 kPa.m3.kg−1 and 77.48 ± 5.72 kPa.m3.kg−1 to 2.67 ± 0.43 kPa.m3.kg−1 and 46.05 ± 9.86 kPa.m3.kg−1, respectively after incorporation of 10 wt.% n-octadecane. However, as the foam cell size reduced by increasing the PCM content, specific compressive strength and modulus were improved and reached 3.44 ± 0.30 kPa.m3.kg−1 and 65.50 ± 1.16 kPa.m3.kg−1, respectively for composite foam containing 20 wt.% n-octadecane which are comparable to those of PU foam. Additionally, the PCM leakage from this composite foam was less than others. This study suggests that by adjusting the PCM content, one-shot synthesized PU-PCM composite foams can provide not only reasonable thermal regulation properties and appropriate thermal reliability but also sufficient mechanical properties.

Similar content being viewed by others

References

Yang C, Fischer L, Maranda S, Worlitschek J (2015) Rigid polyurethane foams incorporated with phase change materials: A state-of-the-art review and future research pathways. Energy Build 87:25–36. https://doi.org/10.1016/j.enbuild.2014.10.075

Baetens R, Jelle BP, Gustavsen A (2010) Phase change materials for building applications: A state-of-the-art review. Energy Build 42:1361–1368. https://doi.org/10.1016/j.enbuild.2010.03.026

Kalnæs SE, Jelle BP (2015) Phase change materials and products for building applications: A state-of-the-art review and future research opportunities. Energy Build 94:150–176. https://doi.org/10.1016/j.enbuild.2015.02.023

Marin P, Saffari M, de Gracia A et al (2016) Energy savings due to the use of PCM for relocatable lightweight buildings passive heating and cooling in different weather conditions. Energy Build 129:274–283. https://doi.org/10.1016/j.enbuild.2016.08.007

Saffari M, De Gracia A, Ushak S, Cabeza LF (2016) Economic impact of integrating PCM as passive system in buildings using Fanger comfort model. Energy Build 112:159–172. https://doi.org/10.1016/j.enbuild.2015.12.006

Ikutegbe CA, Farid MM (2020) Application of phase change material foam composites in the built environment: A critical review. Renew Sustain Energy Rev 131:110008. https://doi.org/10.1016/j.rser.2020.110008

Ahmadi Y, Kim K-H, Kim S, Tabatabaei M (2020) Recent advances in polyurethanes as efficient media for thermal energy storage. Energy Storage Mater 30:74–86. https://doi.org/10.1016/j.ensm.2020.05.003

Amaral C, Pinto SC, Silva T et al (2020) Development of polyurethane foam incorporating phase change material for thermal energy storage. J Energy Storage 28:101177. https://doi.org/10.1016/j.est.2019.101177

Delgado JMPQ, Martinho JC, Vaz Sá A, et al (2019) Thermal Energy Storage with Phase Change Materials, A Literature Review of Applications for Buildings Materials. 73

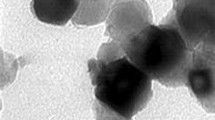

Liao H, Liu Y, Chen R, Wang Q (2021) Preparation and characterization of polyurethane foams containing microencapsulated phase change materials for thermal energy storage and thermal regulation. Polym Int 70:619–627. https://doi.org/10.1002/pi.6145

Aydin AA, Okutan H (2013) Polyurethane rigid foam composites incorporated with fatty acid ester-based phase change material. Energy Convers Manag 68:74–81. https://doi.org/10.1016/j.enconman.2012.12.015

Sarier N, Onder E (2008) Thermal insulation capability of PEG-containing polyurethane foams. Thermochim Acta 475:15–21. https://doi.org/10.1016/j.tca.2008.06.006

Sarier N, Onder E (2007) Thermal characteristics of polyurethane foams incorporated with phase change materials. Thermochim Acta 454:90–98. https://doi.org/10.1016/j.tca.2006.12.024

Liang S, Zhu Y, Wang H et al (2016) Preparation and Characterization of Thermoregulated Rigid Polyurethane Foams Containing Nanoencapsulated Phase Change Materials. Ind Eng Chem Res 55:2721–2730. https://doi.org/10.1021/acs.iecr.5b04543

Minogue E (2000) An in-situ study of the nucleation process of polyurethane rigid foam formation. Dublin City University

Brondi C, Di Maio E, Bertucelli L et al (2021) Competing bubble formation mechanisms in rigid polyurethane foaming. Polymer (Guildf) 228:123877. https://doi.org/10.1016/j.polymer.2021.123877

Vehkamäki, H (2006) Classical Nucleation Theory in Multicomponent Systems. Springer-Verlag, Berlin/Heidelberg

Sánchez-Calderón I, Bernardo V, Santiago-Calvo M et al (2021) Effect of the Molecular Structure of TPU on the Cellular Structure of Nanocellular Polymers Based on PMMA/TPU Blends. Polymers (Basel) 13:3055. https://doi.org/10.3390/polym13183055

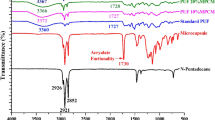

Wong CS, Badri KH (2012) Chemical Analyses of Palm Kernel Oil-Based Polyurethane Prepolymer. Mater Sci Appl 03:78–86. https://doi.org/10.4236/msa.2012.32012

Lin-Vien D, Colthup NB, Fateley WG, Grasselli JG (1991) CHAPTER 9 - Compounds Containing the Carbonyl Group. In: Lin-Vien D, Colthup NB, Fateley WG, Grasselli JG (eds) The Handbook of Infrared and Raman Characteristic Frequencies of Organic Molecules. Academic Press, San Diego, pp 117–154

Li S, Li C, Li C et al (2013) Fabrication of nano-crystalline cellulose with phosphoric acid and its full application in a modified polyurethane foam. Polym Degrad Stab 98:1940–1944. https://doi.org/10.1016/j.polymdegradstab.2013.06.017

Lin-Vien D, Colthup NB, Fateley WG, Grasselli JG (1991) CHAPTER 2 - Alkanes. In: Lin-Vien D, Colthup NB, Fateley WG, Grasselli JG (eds) The Handbook of Infrared and Raman Characteristic Frequencies of Organic Molecules. Academic Press, San Diego, pp 9–28

Pinto ERP, Barud HS, Polito WL et al (2013) Preparation and characterization of the bacterial cellulose/polyurethane nanocomposites. J Therm Anal Calorim 114:549–555. https://doi.org/10.1007/s10973-013-3001-y

Xie B, Liu G, Jiang S et al (2008) Crystallization Behaviors of n -Octadecane in Confined Space: Crossover of Rotator Phase from Transient to Metastable Induced by Surface Freezing. J Phys Chem B 112:13310–13315. https://doi.org/10.1021/jp712160k

You M, Zhang XX, Li W, Wang XC (2008) Effects of MicroPCMs on the fabrication of MicroPCMs/polyurethane composite foams. Thermochim Acta 472:20–24. https://doi.org/10.1016/j.tca.2008.03.006

You M, Zhang X, Wang J, Wang X (2009) Polyurethane foam containing microencapsulated phase-change materials with styrene-divinybenzene co-polymer shells. J Mater Sci 44:3141–3147. https://doi.org/10.1007/s10853-009-3418-7

You M, Zhang XX, Wang XC et al (2010) Effects of type and contents of microencapsuled n-alkanes on properties of soft polyurethane foams. Thermochim Acta 500:69–75. https://doi.org/10.1016/j.tca.2009.12.013

Tinti A, Tarzia A, Passaro A, Angiuli R (2014) Thermographic analysis of polyurethane foams integrated with phase change materials designed for dynamic thermal insulation in refrigerated transport. Appl Therm Eng 70:201–210. https://doi.org/10.1016/j.applthermaleng.2014.05.003

Qu L, Li A, Gu J, Zhang C (2018) Thermal Energy Storage Capability of Polyurethane Foams Incorporated with Microencapsulated Phase Change Material. Chemistry Select 3:3180–3186. https://doi.org/10.1002/slct.201703043

Zhu Y, Qin Y, Liang S et al (2019) Nanoencapsulated phase change material with polydopamine-SiO 2 hybrid shell for tough thermo-regulating rigid polyurethane foam. Thermochim Acta 676:104–114. https://doi.org/10.1016/j.tca.2019.04.005

Cholakova D, Denkov N (2019) Rotator phases in alkane systems: In bulk, surface layers and micro/nano-confinements. Adv Colloid Interface Sci 269:7–42. https://doi.org/10.1016/j.cis.2019.04.001

Zhang XX, Fan YF, Tao XM, Yick KL (2005) Crystallization and prevention of supercooling of microencapsulated n-alkanes. J Colloid Interface Sci 281:299–306. https://doi.org/10.1016/j.jcis.2004.08.046

Wang X, Li C, Wang M et al (2020) Bifunctional microcapsules with n-octadecane/thyme oil core and polyurea shell for high-efficiency thermal energy storage and antibiosis. Polymers (Basel) 12:1–16. https://doi.org/10.3390/polym12102226

Woo HY, Lee DW, Yoon TY et al (2021) Sub-100-nm nearly monodisperse n-paraffin/pmma phase change nanobeads. Nanomaterials 11:1–9. https://doi.org/10.3390/nano11010204

Oliver MJ, Calvert PD (1975) Homogeneous nucleation of n-alkanes measured by differential scanning calorimetry. J Cryst Growth 30:343–351. https://doi.org/10.1016/0022-0248(75)90010-X

Faraj K, Khaled M, Faraj J et al (2020) Phase change material thermal energy storage systems for cooling applications in buildings: A review. Renew Sustain Energy Rev 119:109579. https://doi.org/10.1016/j.rser.2019.109579

Galvagnini F, Dorigato A, Valentini F, Fiore V, La Gennusa M, Pegoretti A (2020) Multifunctional polyurethane foams with thermal energy storage/release capability. J Therm Anal Calorim 1–17. https://doi.org/10.1007/s10973-020-10367-w

Qiu X, Lu L, Tang G, Song G (2021) Preparation and thermal properties of microencapsulated paraffin with polyurea/acrylic resin hybrid shells as phase change energy storage materials. J Therm Anal Calorim 1–10. https://doi.org/10.1007/s10973-020-09354-y

Liu X, Hao J, Gaan S (2016) Recent studies on the decomposition and strategies of smoke and toxicity suppression for polyurethane based materials. RSC Adv 6:74742–74756. https://doi.org/10.1039/C6RA14345H

Alobad ZK, Albozahid M, Naji HZ et al (2021) Influence of hard segments content on thermal, morphological and mechanical properties of homo and co-polyurethanes: a comparative study. Arch Mater Sci Eng 1:5–16. https://doi.org/10.5604/01.3001.0015.0510

Silva MC, Takahashi JA, Chaussy D et al (2010) Composites of rigid polyurethane foam and cellulose fiber residue. J Appl Polym Sci 117:3665–3672. https://doi.org/10.1002/app.32281

Leng W, Pan B (2019) Thermal insulating and mechanical properties of cellulose nanofibrils modified polyurethane foam composite as structural insulated material. Forests 10:200. https://doi.org/10.3390/f10020200

Fan H, Tekeei A, Suppes GJ, Hsieh FH (2012) Properties of biobased rigid polyurethane foams reinforced with fillers: Microspheres and nanoclay Int J Polym Sci. https://doi.org/10.1155/2012/474803

Acknowledgements

This work was supported by Hormozgan Electric Distribution Company (HEDC) (Project No. 980211) and Shahid Beheshti University. The authors gratefully acknowledge research Laboratories of Shahid Beheshti University, Zirab Campus for technical support and Arian Polyurethane JSC for kindly providing ingredients used for synthesis of polyurethane.

Funding

This work was supported by Hormozgan Electric Distribution Company (HEDC) (Project No. 980211) and Shahid Beheshti University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Vatankhah, E., Abasnezhad, M., Nazerian, M. et al. Thermal energy storage and mechanical performance of composites of rigid polyurethane foam and phase change material prepared by one-shot synthesis method. J Polym Res 29, 81 (2022). https://doi.org/10.1007/s10965-022-02911-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-02911-z