Abstract

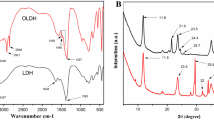

Anionic waterborne polyurethane (aWPU) composites were fabricated using hydoxytelechelic epoxidized natural rubber (HTENR) and silica, extracted from rice husk ash (RHA). Silica was then modified by poly(diallyldimethyl ammonium chloride) (PDDA), a cationic polymer. The PDDA content attached to the modified particles was about 4.43%. PDDA-SiO2 particles were smaller and the size distribution narrower than pristine SiO2 due to deagglomeration. The chemical structure of PDDA-SiO2 was confirmed by Fourier infrared spectroscopy (FTIR). PDDA-SiO2 particles were then loaded in aWPU at contents of 0.5 to 5.0% wt. using self-assembly by electrostatic interaction and hydrogen bonding between PDDA-SiO2 particle and aWPU. At PDDA-SiO2 loadings of 0.5 to 1.5% wt., aWPU/PDDA-SiO2 composites formed homogenous emulsions and transparent films. PDDA-SiO2 loadings of 3.0% wt. and 5.0% wt. produced PDDA-SiO2 agglomerations and filler clusters were seen in the obtained films due to poor dispersion of PDDA-SiO2 particles in the WPU matrix. PDDA-SiO2 incorporation increased Tg and raised the degradation temperature at 10% weight loss from 276 °C to 300 °C but reduced tensile strength compared to neat aWPU. Due to the insufficient interaction of aWPU and PDDA-SiO2 in case of physical mixing, sedimentation of PDDA-SiO2 particles in the PU matrix was observed but with PDDA modification the particles were uniformly embedded in nano-scale clusters.

Similar content being viewed by others

Data Availability

The raw data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

Code availability

Not applicable.

References

Mohaghegh SMS, Barikani M, Entezami AA (2005) Preparation and properties of aqueous polyurethane dispersions. Iran Polym J English Ed 14:163–167

Sukhawipat N, Saetung N, Pasetto P et al (2020) A novel high adhesion cationic waterborne polyurethane for green coating applications. Prog Org Coatings 148:105854. https://doi.org/10.1016/j.porgcoat.2020.105854

Król B, Król P (2009) Synthesis and characterisation of coating polyurethane cationomers containing quaternary ammonium alkyl groups derived from built-in alkyl bromides. Colloid Polym Sci 287:189–201. https://doi.org/10.1007/S00396-008-1966-Z/TABLES/7

Saetung A, Kaenhin L, Klinpituksa P et al (2012) Synthesis, characteristic, and properties of waterborne polyurethane based on natural rubber. J Appl Polym Sci 124:2742–2752. https://doi.org/10.1002/app.35318

Noreen A, Zia KM, Zuber M et al (2016) Recent trends in environmentally friendly water-borne polyurethane coatings: A review. Korean J Chem Eng 33:388–400

Pandya H, Mahanwar P (2020) Fundamental insight into anionic aqueous polyurethane dispersions. Adv Ind Eng Polym Res 3:102–110. https://doi.org/10.1016/j.aiepr.2020.07.003

Lin WT, Lee WJ (2017) Effects of the NCO/OH molar ratio and the silica contained on the properties of waterborne polyurethane resins. Colloids Surfaces A Physicochem Eng Asp 522:453–460. https://doi.org/10.1016/j.colsurfa.2017.03.022

Hormaiztegui MEV, Mucci VL, Santamaria-Echart A et al (2016) Waterborne polyurethane nanocomposites based on vegetable oil and microfibrillated cellulose. J Appl Polym Sci 133. https://doi.org/10.1002/app.44207

Jia-Hu G, Yu-Cun L, Tao C et al (2015) Synthesis and properties of a nano-silica modified environmentally friendly polyurethane adhesive. RSC Adv 5:44990–44997. https://doi.org/10.1039/c5ra01965f

Han Y, Hu J, Xin Z (2018) In-situ incorporation of alkyl-grafted silica into waterborne polyurethane with high solid content for enhanced physical properties of coatings. Polymers (Basel) 10. https://doi.org/10.3390/polym10050514

Rahman MM (2017) Stability and properties of waterborne polyurethane/clay nanocomposite dispersions. J Coatings Technol Res 14:1357–1368. https://doi.org/10.1007/s11998-017-9944-3

Kim BK, Seo JW, Jeong HM (2003) Morphology and properties of waterborne polyurethane/clay nanocomposites. Eur Polym J 39:85–91. https://doi.org/10.1016/S0014-3057(02)00173-8

Chen SG, Hu JW, Zhang MQ et al (2004) Gas sensitivity of carbon black/waterborne polyurethane composites. Carbon N Y 42:645–651. https://doi.org/10.1016/j.carbon.2004.01.002

Zhao B, Fu RW, Zhang MQ et al (2006) Effect of soft segments of waterborne polyurethane on organic vapor sensitivity of carbon black filled waterborne polyurethane composites. Polym J 38:799–806. https://doi.org/10.1295/polymj.PJ2005202

Luo Z, Hong RY, Xie HD, Feng WG (2012) One-step synthesis of functional silica nanoparticles for reinforcement of polyurethane coatings. Powder Technol 218:23–30. https://doi.org/10.1016/j.powtec.2011.11.023

Zhang L, Zhang H, Guo J (2012) Synthesis and Properties of UV-Curable Polyester-Based Waterborne Polyurethane/Functionalized Silica Composites and Morphology of Their Nanostructured Films. https://doi.org/10.1021/ie3000248

Wu Z, Wang H, Tian X et al (2014) Surface and mechanical properties of hydrophobic silica contained hybrid films of waterborne polyurethane and fluorinated polymethacrylate. Polym (United Kingdom) 55:187–194. https://doi.org/10.1016/j.polymer.2013.11.019

Peng Z, Kong LX, Li SD (2005) Non-isothermal crystallisation kinetics of self-assembled polyvinyl alcohol/silica nano-composite. Polymer (Guildf) 46:1949–1955. https://doi.org/10.1016/j.polymer.2004.12.026

Peng Z, Kong LX, Li SD et al (2007) Self-assembled natural rubber/silica nanocomposites: Its preparation and characterization. Compos Sci Technol 67:3130–3139. https://doi.org/10.1016/j.compscitech.2007.04.016

Li SD, Peng Z, Kong LX, Zhong JP (2006) Thermal degradation kinetics and morphology of natural rubber/silica nanocomposites. J Nanosci Nanotechnol 6:541–546. https://doi.org/10.1166/jnn.2006.114

Panda SS, Panda BP, Mohanty S, Nayak SK (2017) Synthesis and properties of castor oil-based waterborne polyurethane cloisite 30B nanocomposite coatings. J Coatings Technol Res 14:377–394. https://doi.org/10.1007/s11998-016-9855-8

Lu Y, Larock RC (2008) Soybean-oil-based waterborne polyurethane dispersions: Effects of polyol functionality and hard segment content on properties. Biomacromol 9:3332–3340. https://doi.org/10.1021/bm801030g

Lu Y, Xia Y, Larock RC (2011) Surfactant-free core–shell hybrid latexes from soybean oil-based waterborne polyurethanes and poly(styrene-butyl acrylate). Prog Org Coatings 71:336–342. https://doi.org/10.1016/j.porgcoat.2011.03.027

Mizera K, Ryszkowska J (2016) Polyurethane elastomers from polyols based on soybean oil with a different molar ratio. Polym Degrad Stab 132:21–31. https://doi.org/10.1016/j.polymdegradstab.2016.05.004

Saalah S, Abdullah LC, Aung MM et al (2015) Waterborne polyurethane dispersions synthesized from jatropha oil. Ind Crops Prod 64:194–200. https://doi.org/10.1016/j.indcrop.2014.10.046

Lalita K, Pirote Klinpituksa A, Rungvichaniwat AL (2012) Synthesis and characterisation of waterborne polyurethane adhesives from hydroxyl terminated natural rubber. J Rubber Res 15:217–229

Saetung A, Tsupphayakorn-Ake P, Tulyapituk T et al (2015) The chain extender content and NCO/OH ratio flexibly tune the properties of natural rubber-based waterborne polyurethanes. J Appl Polym Sci 132:42505. https://doi.org/10.1002/app.42505

Sukhawipat N, Saetung N, Pilard JF et al (2018) Synthesis and characterization of novel natural rubber based cationic waterborne polyurethane: Effect of emulsifier and diol class chain extender. J Appl Polym Sci 135. https://doi.org/10.1002/app.45715

Panwiriyarat W, Tanrattanakul V, Pilard JF et al (2013) Effect of the diisocyanate structure and the molecular weight of diols on bio-based polyurethanes. J Appl Polym Sci 130:453–462. https://doi.org/10.1002/app.39170

Panwiriyarat W, Tanrattanakul V, Pilard JF et al (2016) Elaboration and properties of renewable polyurethanes based on natural rubber and biodegradable poly(butylene succinate) soft segments. J Appl Polym Sci 133. https://doi.org/10.1002/app.42943

Saetung A, Rungvichaniwat A, Campistron I et al (2010) Preparation and physico-mechanical, thermal, and acoustic properties of flexible polyurethane foams based on hydroxytelechelic natural rubber. J Appl Polym Sci 117:828–837. https://doi.org/10.1002/app.31601

Sukhawipat N, Raksanak W, Kalkornsurapranee E et al (2020) A new hybrid waterborne polyurethane coating synthesized from natural rubber and rubber seed oil with grafted acrylate. Prog Org Coatings 141:105554. https://doi.org/10.1016/j.porgcoat.2020.105554

Sukhawipat N, Saetung N, Pilard JF et al (2020) Effects of molecular weight of hydroxyl telechelic natural rubber on novel cationic waterborne polyurethane: A new approach to water-based adhesives for leather applications. Int J Adhes Adhes 99:102593. https://doi.org/10.1016/J.IJADHADH.2020.102593

Santana Costa JA, Paranhos CM (2018) Systematic evaluation of amorphous silica production from rice husk ashes. J Clean Prod 192:688–697. https://doi.org/10.1016/j.jclepro.2018.05.028

Saetung A, Rungvichaniwat A, Tsupphayakorn-ake P et al (2016) Properties of waterborne polyurethane films: effects of blend formulation with hydroxyl telechelic natural rubber and modified rubber seed oils. J Polym Res 2312(23):1–10. https://doi.org/10.1007/S10965-016-1160-9

Sun W (2008) FTIR analysis of adsorption of poly diallyl-dimethyl-ammonium chloride on kaolinite. J Cent South Univ Technol 15:373–377. https://doi.org/10.1007/s11771−008−0070−3

Zhou T, Wang M, He X, Qiao J (2019) Poly(vinyl alcohol)/Poly(diallyldimethylammonium chloride) anion-exchange membrane modified with multiwalled carbon nanotubes for alkaline fuel cells. J Mater 5:286–295. https://doi.org/10.1016/j.jmat.2019.01.012

Santos JC, Vieira LMG, Panzera TH et al (2015) Hybrid glass fibre reinforced composites with micro and poly-diallyldimethylammonium chloride (PDDA) functionalized nano silica inclusions. Mater Des 65:543–549. https://doi.org/10.1016/j.matdes.2014.09.052

Jafari V, Allahverdi A (2014) Synthesis and characterization of colloidal nanosilica via an ultrasound assisted route based on alkali leaching of silica fume. Int J Nanosci Nanotechnol 10:145–152

Sankar S, Sharma SK, Kaur N et al (2016) Biogenerated silica nanoparticles synthesized from sticky, red, and brown rice husk ashes by a chemical method. Ceram Int 42:4875–4885. https://doi.org/10.1016/j.ceramint.2015.11.172

Jung DH, Jeong MA, Jeong HM, Kim BK (2010) Chemical hybridization of imidized waterborne polyurethane with silica particle. Colloid Polym Sci 288:1465–1470. https://doi.org/10.1007/s00396-010-2279-6

Qiao J, Fu J, Liu L et al (2012) Highly stable hydroxyl anion conducting membranes poly(vinyl alcohol)/poly(acrylamide-co-diallyldimethylammonium chloride) (PVA/PAADDA) for alkaline fuel cells: Effect of cross-linking. Int J Hydrogen Energy 37:4580–4589. https://doi.org/10.1016/j.ijhydene.2011.06.038

Jang MK, Hartwig A, Kim BK (2009) Shape memory polyurethanes cross-linked by surface modified silica particles. J Mater Chem 19:1166–1172. https://doi.org/10.1039/B816691A

Sardon H, Irusta L, Aguirresarobe RH, Fernández-Berridi MJ (2014) Polymer/silica nanohybrids by means of tetraethoxysilane sol-gel condensation onto waterborne polyurethane particles. Prog Org Coatings 77:1436–1442. https://doi.org/10.1016/j.porgcoat.2014.04.032

Xinrong S, Nanfang W, Kunyang S et al (2014) Synthesis and characterization of waterborne polyurethane containing UV absorption group for finishing of cotton fabrics. J Ind Eng Chem 20:3228–3233. https://doi.org/10.1016/j.jiec.2013.12.003

Ou J, Zhang M, Liu H et al (2015) Matting films prepared from waterborne acrylic/micro-SiO2 blends. J Appl Polym Sci 132:1–8. https://doi.org/10.1002/app.41707

Poussard L, Lazko J, Mariage J et al (2016) Biobased waterborne polyurethanes for coating applications: How fully biobased polyols may improve the coating properties. Prog Org Coatings 97:175–183. https://doi.org/10.1016/j.porgcoat.2016.04.003

Gaddam SK, Palanisamy A (2017) Anionic waterborne polyurethane-imide dispersions from cottonseed oil based ionic polyol. Ind Crops Prod 96:132–139. https://doi.org/10.1016/j.indcrop.2016.11.054

Guo J, Chai T, Liu Y et al (2018) Kinetic research on the curing reaction of hydroxyl-terminated polybutadiene based polyurethane binder system via FT-IR measurements. Coatings 8. https://doi.org/10.3390/coatings8050175

Pérez-Limiñana MA, Arán-Aís F, Torró-Palau AM et al (2007) Influence of the hard-to-soft segment ratio on the adhesion of water-borne polyurethane adhesive. J Adhes Sci Technol 21:755–773. https://doi.org/10.1163/156856107781362635

Sengloyluan K, Sahakaro K, Dierkes WK, Noordermeer JWM (2014) Silica-reinforced tire tread compounds compatibilized by using epoxidized natural rubber. Eur Polym J 51:69–79. https://doi.org/10.1016/j.eurpolymj.2013.12.010

Xu T, Jia Z, Luo Y et al (2015) Interfacial interaction between the epoxidized natural rubber and silica in natural rubber/silica composites. Appl Surf Sci 328:306–313. https://doi.org/10.1016/j.apsusc.2014.12.029

Jeon HT, Jang MK, Kim BK, Kim KH (2007) Synthesis and characterizations of waterborne polyurethane-silica hybrids using sol-gel process. Colloids Surfaces A Physicochem Eng Asp 302:559–567. https://doi.org/10.1016/J.COLSURFA.2007.03.043

Sun D, Miao X, Zhang K et al (2011) Triazole-forming waterborne polyurethane composites fabricated with silane coupling agent functionalized nano-silica. J Colloid Interface Sci 361:483–490. https://doi.org/10.1016/j.jcis.2011.05.062

Han Y, Chen Z, Dong W, Xin Z (2015) Improved water resistance, thermal stability, and mechanical properties of waterborne polyurethane nanohybrids reinforced by fumed silica via in situ polymerization. High Perform Polym 27:824–832. https://doi.org/10.1177/0954008314563058

Serkis M, Špírková M, Hodan J, Kredatusová J (2016) Nanocomposites made from thermoplastic waterborne polyurethane and colloidal silica. The influence of nanosilica type and amount on the functional properties. Prog Org Coatings 101:342–349. https://doi.org/10.1016/j.porgcoat.2016.07.021

Hassanajili S, Sajedi MT (2016) Fumed silica/polyurethane nanocomposites: effect of silica concentration and its surface modification on rheology and mechanical properties. Iran Polym J English Ed 25:697–710. https://doi.org/10.1007/s13726-016-0458-0

Acknowledgements

The authors are grateful for the financial support provided by the Rajamangala University of Technology Srivijaya and the Faculty of Science, Prince of Songkla University. We also acknowledge the Division of Physical Science for all facilities and Mr. Thomas Coyne for his kind assistance in editing the English text.

Funding

This work is financial support by the Rajamangala University of Technology Srivijaya for a Ph.D. scholarship for Miss Kwanruethai Boonsong, and the Faculty of Science, Prince of Songkla University for chemicals, materials, and facilities.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by Miss Kwanruethai Boonsong. The first draft of the manuscript was written by Miss Chuanpit Khaokong and Miss Kwanruethai Boonsong. The writing, review, and editing were done by Miss Chuanpit Khaokong and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Boonsong, K., Khaokong, C. Preparation of anionic waterborne polyurethane composites with silica from rice husk ash. J Polym Res 29, 40 (2022). https://doi.org/10.1007/s10965-022-02903-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-02903-z