Abstract

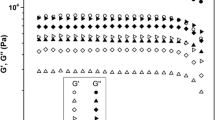

Role of natural rubber (NR) on modifying the interface, morphology and mechanical properties of polypropylene (PP)-NR blend system, is investigated. PP-NR blends with different loading of NR (0, 10, 20, 30, 40, and 50 wt/wt %) were prepared via melt mixing technique. NR, depending on its loading, actuates dramatic phase morphology transformation; from well-discrete matrix droplet to a co-continuous type morphology. This in turn lowers the relaxation of dispersed NR phase as evident by rheological studies. Similarly, the coarsening of morphology from discrete droplet-matrix structure produces synergistic improvement in mechanical properties especially the impact strength. Besides, contact angle studies were carried out to determine the various wettability parameters and the interfacial energy is theoretically calculated using geometric-mean equation.

Similar content being viewed by others

References

Utracki LA (1999) Polymer Blends Handbook. Kluwer Academic Publishers

Noolandi J, Hong KM (1982) Interfacial Properties of Immiscible Homopolymer Blends in the Presence of Block Copolymers. Macromolecules 15:482–492. https://doi.org/10.1021/ma00230a054

Lacroix C, Bousmina M, Carreaut PJ et al (1996) Properties of PETG / EVA Blends : Viscoelastic, Morphological and Interfacial Properties. Polymer 37:2939–2947

Wu D, Yuan L, Laredo E et al (2012) Interfacial properties, viscoelasticity, and thermal behaviors of poly(butylene succinate)/polylactide blend. Ind Eng Chem Res 51:2290–2298. https://doi.org/10.1021/ie2022288

Wu J (2003) The interfacial properties and porous structures of polymer blends characterized by synchrotron small-angle X-ray scattering. Polymer 44:8033–8040. https://doi.org/10.1016/j.polymer.2003.09.059

Wu H, Ning N, Zhang L et al (2013) Effect of additives on the morphology evolution of EPDM/PP TPVs during dynamic vulcanization in a twin-screw extruder. J Polym Res 20:266. https://doi.org/10.1007/s10965-013-0266-6

Utracki LA (1995) History of commercial polymer alloys and blends (from a perspective of the patent literature). Polym Eng Sci 35:2–17. https://doi.org/10.1002/pen.760350103

Pötschke P, Paul DR (2003) Formation of Co-continuous Structures in Melt-Mixed Immiscible Polymer Blends. J Macromol Sci Part C Polym Rev 43:87–141. https://doi.org/10.1081/MC-120018022

Navarro-Baena I, Sessini V, Dominici F et al (2016) Design of biodegradable blends based on PLA and PCL: From morphological, thermal and mechanical studies to shape memory behavior. Polym Degrad Stab 132:97–108. https://doi.org/10.1016/j.polymdegradstab.2016.03.037

Muthuraj R, Misra M, Mohanty AK (2018) Biodegradable compatibilized polymer blends for packaging applications: A literature review. J Appl Polym Sci 135:46279. https://doi.org/10.1002/app.46279

Cao X, Dong W, He M et al (2019) Effects of blending sequences and molecular structures of the compatibilizers on the morphology and properties of PLLA/ABS blends. RSC Adv 9:2189–2198. https://doi.org/10.1039/C8RA09193E

Crawford KE, Sita LR (2015) De Novo Design of a New Class of “Hard–Soft” Amorphous, Microphase-Separated, Polyolefin Block Copolymer Thermoplastic Elastomers. ACS Macro Lett 4:921–925. https://doi.org/10.1021/acsmacrolett.5b00447

Zhou C, Wei Z, Jin C et al (2018) Fully biobased thermoplastic elastomers: Synthesis of highly branched linear comb poly(β-myrcene)-graft-poly(l-lactide) copolymers with tunable mechanical properties. Polymer 138:57–64. https://doi.org/10.1016/j.polymer.2018.01.045

Wang W, Lu W, Goodwin A et al (2019) Recent advances in thermoplastic elastomers from living polymerizations: Macromolecular architectures and supramolecular chemistry. Prog Polym Sci 95:1–31. https://doi.org/10.1016/j.progpolymsci.2019.04.002

Ruiz de Ballesteros O, De Rosa C, Auriemma F et al (2016) Thermoplastic elastomers from binary blends of syndiotactic polypropylenes with different stereoregularity. Polymer 85:114–124. https://doi.org/10.1016/j.polymer.2016.01.036

Parker AJ, Rottler J (2015) Molecular Mechanisms of Plastic Deformation in Sphere-Forming Thermoplastic Elastomers. Macromolecules 48:8253–8261. https://doi.org/10.1021/acs.macromol.5b01339

Puskas JE, Chen Y (2004) Biomedical application of commercial polymyers and novel polyisobutylene-based thermoplastic elastomers for soft tissue replacement. Biomacromol 5:1141–1154. https://doi.org/10.1021/bm034513k

Lee S, Lee K, Jang J et al (2017) Sustainable poly(ε-decalactone)−poly(l-lactide) multiarm star copolymer architectures for thermoplastic elastomers with fixed molar mass and block ratio. Polymer 112:306–317. https://doi.org/10.1016/j.polymer.2017.02.008

McMullin E, Rebar HT, Mather PT (2016) Biodegradable Thermoplastic Elastomers Incorporating POSS: Synthesis, Microstructure, and Mechanical Properties. Macromolecules 49:3769–3779. https://doi.org/10.1021/acs.macromol.6b00470

Shibulal GS, Naskar K (2011) RFL coated aramid short fiber reinforced thermoplastic elastomer: Mechanical, rheological and morphological characteristics. J Polym Res 18:2295–2306. https://doi.org/10.1007/s10965-011-9643-1

Cohn D, Hotovely-Salomon A (2005) Biodegradable multiblock PEO/PLA thermoplastic elastomers: Molecular design and properties. Polymer 46:2068–2075. https://doi.org/10.1016/j.polymer.2005.01.012

Benmesli S, Riahi F (2014) Dynamic mechanical and thermal properties of a chemically modi fi ed polypropylene / natural rubber thermoplastic elastomer blend. Polym Test 36:54–61. https://doi.org/10.1016/j.polymertesting.2014.03.016

Carvalho AJ, Job A, Alves N et al (2003) Thermoplastic starch/natural rubber blends. Carbohydr Polym 53:95–99. https://doi.org/10.1016/S0144-8617(03)00005-5

Ibrahim A, Dahlan M (1998) Thermoplastic Natural Rubber. Prog Polym Sci 23:665–706

Pechurai W, Ã CN, Sahakaro K, (2008) Thermoplastic natural rubber based on oil extended NR and HDPE blends : Blend compatibilizer, phase inversion composition and mechanical properties. Polym Test 27:621–631. https://doi.org/10.1016/j.polymertesting.2008.04.001

Sasdipan K, Kaesaman A, Nakason C (2012) Thermoplastic Natural Rubber Based on Blending of Co-Polyester: Effect of Amount of Epoxide Groups in Epoxidized Natural Rubber on Preperties. Adv Mater Res 626:50–53. https://doi.org/10.4028/www.scientific.net/AMR.626.50

Drakopoulos SX, Karger-Kocsis J, Kmetty Á et al (2017) Thermoplastic starch modified with microfibrillated cellulose and natural rubber latex: A broadband dielectric spectroscopy study. Carbohydr Polym 157:711–718. https://doi.org/10.1016/j.carbpol.2016.10.036

Mahendra IP, Wirjosentono B, Tamrin et al (2019) The influence of maleic anhydride-grafted polymers as compatibilizer on the properties of polypropylene and cyclic natural rubber blends. J Polym Res 26:215. https://doi.org/10.1007/s10965-019-1878-2

Utracki LA (1991) On the viscosity-concentration dependence of immiscible polymer blends. J Rheol (N Y N Y) 35:1615–1637. https://doi.org/10.1122/1.550248

Münstedt H (1981) Rheology of rubber-modified polymer melts. Polym Eng Sci 21:259–270. https://doi.org/10.1002/pen.760210503

C S (2020) Interfacial characterization of immiscible polymer blends using rheology. In: Rheology of Polymer Blends and Nanocomposites. Elsevier, pp 31–48

Ma LF, Bao RY, Dou R et al (2016) Conductive thermoplastic vulcanizates (TPVs) based on polypropylene (PP)/ethylene-propylene-diene rubber (EPDM) blend: From strain sensor to highly stretchable conductor. Compos Sci Technol 128:176–184. https://doi.org/10.1016/j.compscitech.2016.04.001

Li S, Xiao M, Wei D et al (2009) The melt grafting preparation and rheological characterization of long chain branching polypropylene. Polymer 50:6121–6128. https://doi.org/10.1016/j.polymer.2009.10.006

Delgadillo-Velzquez O, Hatzikiriakos SG, Sentmanat M (2008) Thermorheological properties of LLDPE/LDPE blends: Effects of production technology of LLDPE. J Polym Sci Part B Polym Phys 46:1669–1683. https://doi.org/10.1002/polb.21504

Li R, Yu W, Zhou C (2006) Rheological Characterization of Droplet-Matrix versus Co-Continuous Morphology. J Macromol Sci Part B Phys 45:889–898. https://doi.org/10.1080/00222340600777496

Ezzati P, Ghasemi I, Karrabi M, Azizi H (2008) Rheological Behaviour of PP/EPDM Blend: The Effect of Compatibilization. Iran Polym J 17:669–679

Li R, Yu W, Zhou C (2006) Phase behavior and its viscoelastic responses of poly(methyl methacrylate) and poly(styrene-co-maleic anhydride) blend systems. Polym Bull 56:455–466. https://doi.org/10.1007/s00289-005-0499-6

Lohse DJ, Milner ST, Fetters LJ et al (2002) Well-defined, model long chain branched polyethylene. 2. Melt rheological behavior Macromolecules 35:3066–3075. https://doi.org/10.1021/ma0117559

Ryntz RA (1994) Coating adhesion to low surface free energy substrates. Prog Org Coatings 25:73–83. https://doi.org/10.1016/0300-9440(94)00503-6

Denault J, Morese-Seguela B, Seguela R, Prud’homme J (1990) Motional perturbation at the microphase boundary in thermoplastic elastomers. Macromolecules 23:4658–4670. https://doi.org/10.1021/ma00223a026

Men Y, Rieger J, Strobl G (2003) Role of the Entangled Amorphous Network in Tensile Deformation of Semicrystalline Polymers. Phys Rev Lett 91:095502. https://doi.org/10.1103/PhysRevLett.91.095502

Wu S (1985) Phase structure and adhesion in polymer blends : A criterion for rubber toughening *. Polymer 26:1855–1863

Du H, Zhang Y, Liu H et al (2014) Influence of phase morphology and crystalline structure on the toughness of rubber-toughened isotatic polypropylene blends. Polymer 55:5001–5012. https://doi.org/10.1016/j.polymer.2014.08.012

Ishikawa M, Ushui K, Kondo Y et al (1996) Effect of tie molecules on the craze strength of polypropylene. Polymer 37:5375–5379. https://doi.org/10.1016/S0032-3861(96)00364-3

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The manuscript entitled “Interfacial interaction in polypropylene-natural rubber blends: role of natural rubber on morphological, rheological, and mechanical evolution” by Nithin Chandran, Sarathchandran C, Anjaly Sivadas and Sabu Thomas is not having any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chandran, N., C, S., Sivadas, A. et al. Interfacial interaction in polypropylene-natural rubber blends: role of natural rubber on morphological, rheological, and mechanical evolution. J Polym Res 29, 24 (2022). https://doi.org/10.1007/s10965-021-02873-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02873-8