Abstract

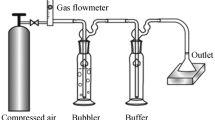

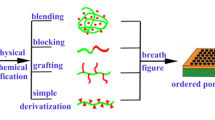

Highly ordered honeycomb films made of biocompatible and biodegradable polymers are in pivotal demand for human-related applications such as tissue engineering and drug delivery. Among several common methods to form these honeycomb-structured films, Breath Figure methods (BFs) are widely used, which usually requires additional surface-active agents and strictly controlled humidity condition. Therefore, it is deficient to utilize BFs for practical applications of intensively used bioresorbable polymers such as polycaprolactone. Herein, we propose a new two-step method to not only surmount the mentioned weakness of BFs but also for the first time produce super-large honeycomb polycaprolactone (hc-PCL) film in the normal indoor environment. In our new method, methanol is exploited to induce a nanoparticle-like layer on the surface of droplets to prevent them from coalescence, which facilitates the formation of the uniformly ordered honeycomb structures. The results showed that the hc-PCL film was successfully fabricated with a large area of up to 5⋅5 cm2 with the pore size tuned in a range of 1÷7 μm. Moreover, by applying the method, the honeycomb structures were successfully imprinted onto non-planar PCL films as well as 3D printed PCL substrate. We believe that the convergence of excellent bio-compatibility and scalable production, as well as ease of turning pattern features would enable new prospects of the hc-PCL to widely be applied in biotechnology with multi-functionality and low-cost production.

Similar content being viewed by others

References

Du C, Zhang A, Bai H, Li L (2012) Robust Microsieves with Excellent Solvent Resistance: Cross-Linkage of Perforated Polymer Films with Honeycomb Structure. ACS Macro Lett 2:27–30

Mansouri J, Yapit E, Chen V (2013) Polysulfone filtration membranes with isoporous structures prepared by a combination of dip-coating and breath figure approach. J Membr Sci 444:237–251

Ghannam L, Garay H, François J, Billon L (2007) New Polymeric Materials with Interferential Optical Properties. Macromol Chem Phys 208:1469–1479

Lim BW, Suh MC (2014) Simple fabrication of a three-dimensional porous polymer film as a diffuser for organic light emitting diodes. Nanoscale 6:14446–14452

Gong J, Xu B, Tao X (2017) Breath Figure Micromolding Approach for Regulating the Microstructures of Polymeric Films for Triboelectric Nanogenerators. ACS Appl Mater Interfaces 9:4988–4997

Dao V-D, Bui V-T, Choi H-S (2018) Pt-coated cylindrical micropatterned honeycomb Petri dishes as an efficient TCO-free counter electrode in liquid junction photovoltaic devices. J Power Sources 376:41–45

Daban G, Bayram C, Bozdoğan B, Denkbaş EB (2019) Porous polyurethane film fabricated via the breath figure approach for sustained drug release. J Appl Polym Sci 136:47658

Ponnusamy T, Lawson LB, Freytag LC et al (2012) In vitro degradation and release characteristics of spin coated thin films of PLGA with a “breath figure” morphology. Biomatter 2:77–86

Akoumeh R, Elzein T, Martínez-Campos E et al (2020) Fabrication of porous films from immiscible polymer blends: Role of the surface structure on the cell adhesion. Polyme Test 91:106797

Bui VT, Thuy LT, Tran QC et al (2017) Ordered honeycomb biocompatible polymer films via a one-step solution-immersion phase separation used as a scaffold for cell cultures. Chem Eng J 320:561–569

Yang F, Murugan R, Ramakrishna S et al (2004) Fabrication of nano-structured porous PLLA scaffold intended for nerve tissue engineering. Biomaterials 25:1891–1900

Yabu H (2018) Fabrication of honeycomb films by the breath figure technique and their applications. Sci Technol Adv Mater 19:802–822

Calejo MT, Ilmarinen T, Skottman H, Kellomäki M (2018) Breath figures in tissue engineering and drug delivery: State-of-the-art and future perspectives. Acta Biomater 66:44–66

Zhang A, Bai H, Li L (2015) Breath Figure: A Nature-Inspired Preparation Method for Ordered Porous Films. Chem Rev 115:9801

Kang DE, Byeon SJ, Heo MS et al (2014) Fabrication of ordered honeycomb structures and microspheres using polystyrene-block-poly(tert-butyl acrylate) star polymers. J Polym Research 21:382

Hosseinzadeh K, Ganji DD, Ommi F (2020) Effect of SiO2 super-hydrophobic coating and self-rewetting fluid on two phase closed thermosyphon heat transfer characteristics: An experimental and numerical study. J Mol Liq 315:113748

Bui VT, Thi Thuy L, Choi JS, Choi HS (2018) Ordered cylindrical micropatterned Petri dishes used as scaffolds for cell growth. J Colloid Interface Sci 513:161–169

Smallwood I (2012) Handbook of organic solvent properties. Butterworth-Heinemann

Bui VT, Lee HS, Choi JH, Choi HS (2015) Highly ordered and robust honeycomb films with tunable pore sizes fabricated via UV crosslinking after applying improved phase separation. Polymer 74:46–53

Hutmacher DW (2000) Scaffolds in tissue engineering bone and cartilage. Biomaterials 21:2529–2543

Acknowledgements

This research is funded by Vietnam National University Ho Chi Minh City (VNU-HCM) under grant number C2021-20-18. We acknowledge the support of time and facilities from Ho Chi Minh City University of Technology (HCMUT), VNU-HCM for this study. This research is also supported by Polymer Research Center, Ho Chi Minh City University of Technology (HCMUT) and Faculty of Applied Sciences, Ho Chi Minh City University of Technology and Education (HCMUTE).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• A simple, cost-effective, and scalable strategy produces uniform honeycomb pattern.

• Large area, highly ordered honeycomb pattern is created on surface of biocompatible bioresorbable polycaprolactone.

• A mixture of chloform and methanol induces phase separation and controls the pattern features.

• The fabrication process has no requirement of external humidity or addition of any surface active agents.

• 3D printed porous PCL is made as a potential artificial ear implant.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nguyen, V., Sam, T.U., Huynh, D.P. et al. Methanol assisted-massive production of surfactant-free ordered honeycomb polycaprolactone film. J Polym Res 29, 16 (2022). https://doi.org/10.1007/s10965-021-02855-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02855-w