Abstract

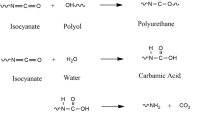

Polyurethane (PU) consists of an organic chain unit joined by carbamate (-NHCOO-) links. A variety of raw materials are used in addition to castor oil to produce polyurethane foam composites. In this attempt, poly-hydroxyl compound (petroleum-based polyol) was substituted by natural oil (plant-based polyol) with 0 – 100 wt.% replacement to fabricate semi-rigid polyurethane foam composites. The polyurethane foam derived from castor oil (PU-CO) was characterized using infrared spectroscopy, thermogravimetric analysis, scanning electron microscopy, compression strength, tensile strength and density, respectively. The cement mortar containing polyurethane semi-rigid foam composites based on castor oil (CM-PU-CO) were also studied using infrared spectroscopy, X-ray photoelectron spectroscopy, Brunauer–Emmett–Teller (BET) analysis, powder X-ray diffraction, thermogravimetric analysis, thermal conductivity and sound absorption coefficient. The results indicated that CM-PU-CO composites are promising energy-saving materials, particularly under harsh climatic conditions, till 50% partial replacement with castor oil. The substitution of petroleum-based poly-hydroxyl compounds with a natural-based polyol, such as castor oil, was very promising.

Similar content being viewed by others

References

Maamoun A, Mahmoud A, Nasr E, Soliman E, Sarwar MI, Zulfiqar S (2019) Fabrication of novel formulations from rigid polyurethane foams and mortar for potential applications in building industry. J Polym Res 26(11):1–10

Mahmoud AA, Nasr EAA, Maamoun AAH (2017) The influence of polyurethane foam on the insulation characteristics of mortar pastes. Journal of Minerals and Materials Characterization and Engineering 5(2):49–61

Zieleniewska M, Leszczyński MK, Szczepkowski L, Bryśkiewicz A, Krzyżowska M, Bień K, Ryszkowska J (2016) Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. Polym Degrad Stab 132:78–86

Akindoyo JO, Beg M, Ghazali S, Islam M, Jeyaratnam N, Yuvaraj A (2016) Polyurethane types, synthesis and applications–a review. RSC Adv 6(115):114453–114482

Szycher M (1999) Szycher’s handbook of polyurethanes. CRC Press, New York

Berardi U, Madzarevic J (2020) Microstructural analysis and blowing agent concentration in aged polyurethane and polyisocyanurate foams. Appl Therm Eng 164:114440

Reignier J, Alcouffe P, Mechin F, Fenouillot F (2019) The morphology of rigid polyurethane foam matrix and its evolution with time during foaming–New insight by cryogenic scanning electron microscopy. J Colloid Interface Sci 552:153–165

Choe H, Choi Y, Kim JH (2019) Threshold cell diameter for high thermal insulation of water-blown rigid polyurethane foams. J Ind Eng Chem 73:344–350

Mahmood N, Yuan Z, Schmidt J, Tymchyshyn M, Xu CC (2016) Hydrolytic liquefaction of hydrolysis lignin for the preparation of bio-based rigid polyurethane foam. Green Chem 18(8):2385–2398

Kattiyaboot T, Thongpin C (2016) Effect of natural oil based polyols on the properties of flexible polyurethane foams blown by distilled water. Energy Procedia 89:177–185

Lee S-T, Ramesh NS (2004) Polymeric foams: mechanisms and materials. CRC Press

Gama NV, Soares B, Freire CS, Silva R, Neto CP, Barros-Timmons A, Ferreira A (2015) Bio-based polyurethane foams toward applications beyond thermal insulation. Mater Des 76:77–85

Das B, Konwar U, Mandal M, Karak N (2013) Sunflower oil based biodegradable hyperbranched polyurethane as a thin film material. Ind Crops Prod 44:396–404

Zhang D, Chen S (2020) The study of palm-oil-based bio-polyol on the morphological, acoustic and mechanical properties of flexible polyurethane foams. Polym Int 69(3):257–264

Cheng Z, Li Q, Yan Z, Liao G, Zhang B, Yu Y, Yi C, Xu Z (2019) Design and synthesis of novel aminosiloxane crosslinked linseed oil-based waterborne polyurethane composites and its physicochemical properties. Prog Org Coat 127:194–201

Mizera K, Ryszkowska J, Kurańska M, Prociak A (2020) The effect of rapeseed oil-based polyols on the thermal and mechanical properties of ureaurethane elastomers. Polym Bull 77(2):823–846

Wang X, Zhang Y, Liang H, Zhou X, Fang C, Zhang C, Luo Y (2019) Synthesis and properties of castor oil-based waterborne polyurethane/sodium alginate composites with tunable properties. Carbohyd Polym 208:391–397

Ji Y, Chen S, Zhu W (2020) The effect of pore numbers in the cell walls of soybean oil polyurethane foam on sound absorption performance. Appl Acoust 157:107010

Petrović ZS (2008) Polyurethanes from vegetable oils. Polym Rev 48(1):109–155

Zhang L, Zhang M, Hu L, Zhou Y (2014) Synthesis of rigid polyurethane foams with castor oil-based flame retardant polyols. Ind Crops Prod 52:380–388

Tavares L, Boas C, Schleder G, Nacas A, Rosa D, Santos D (2016) Bio-based polyurethane prepared from Kraft lignin and modified castor oil. Express Polym Lett 10(11)

Zhou D, Zhao C-Y, Tian Y (2012) Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl Energy 92:593–605

Aditya L, Mahlia T, Rismanchi B, Ng H, Hasan M, Metselaar H, Muraza O, Aditiya H (2017) A review on insulation materials for energy conservation in buildings. Renew Sustain Energy Rev 73:1352–1365

Mohamed MG, Kuo SW (2019) Functional polyimide/polyhedral oligomeric silsesquioxane nanocomposites Polymers 11(1):26

Berardi U, Naldi M (2017) The impact of the temperature dependent thermal conductivity of insulating materials on the effective building envelope performance. Energy Build 144:262–275

Ionescu M (2005) Chemistry and technology of polyols for polyurethanes. iSmithers Rapra Publishing

Lanzón M, García-Ruiz P (2008) Lightweight cement mortars: Advantages and inconveniences of expanded perlite and its influence on fresh and hardened state and durability. Constr Build Mater 22(8):1798–1806

Bartos P, Groot C, Hughes J (1999) International RILEM workshop on historic mortars: Characteristics and Tests. In: Proceedings of the International RILEM Workshop, Paisley, Scotland

Pedro D, De Brito J, Veiga R (2013) Mortars made with fine granulate from shredded tires. J Mater Civ Eng 25(4):519–529

West Conshohocken P (2016) ASTM D1621–16. Standard Test Method for Compressive Properties of Rigid Cellular Plastics, ASTM International

International A (2017) ASTM D1623–17, Standard Test Method for Tensile and Tensile Adhesion Properties of Rigid Cellular Plastics. West Conshohocken, PA

International A (2019) ASTM E1050–19, Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones and a Digital Frequency Analysis System. PA, West Conshohocken

International A (2017) ASTM C518–17, Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. West Conshohocken, PA

Da Silva VR, Mosiewicki MA, Yoshida MI, Da Silva MC, Stefani PM, Marcovich NE (2013) Polyurethane foams based on modified tung oil and reinforced with rice husk ash I: synthesis and physical chemical characterization. Polym Testing 32(2):438–445

Corcuera M, Rueda L, d’Arlas BF, Arbelaiz A, Marieta C, Mondragon I, Eceiza A (2010) Microstructure and properties of polyurethanes derived from castor oil. Polym Degrad Stab 95(11):2175–2184

Samy MM, Mohamed MG, Kuo S-W (2020) Pyrene-functionalized tetraphenylethylene polybenzoxazine for dispersing single-walled carbon nanotubes and energy storage. Compos Sci Technol 199:108360

Donald L, Pavia L, Kriz GS (1979) Introduction to Spectroscopy: a Guide for Studentsof Organic Chemistry. Saunders College

Richard T, Mercury L, Poulet F, d’Hendecourt L (2006) Diffuse reflectance infrared Fourier transform spectroscopy as a tool to characterise water in adsorption/confinement situations. J Colloid Interface Sci 304(1):125–136

Ylmén R, Jäglid U, Steenari BM, Panas I (2009) Early hydration and setting of Portland cement monitored by IR, SEM and Vicat techniques. Cem Concr Res 39(5):433–439

Mollah MY, Kesmez M, Cocke DL (2004) An X-ray diffraction (XRD) and Fourier transform infrared spectroscopic (FT-IR) investigation of the long-term effect on the solidification/stabilization (S/S) of arsenic (V) in Portland cement type-V. Sci Total Environ 325(1–3):255–262

Trezza M, Lavat A (2001) Analysis of the system 3CaO· Al2O3–CaSO4· 2H2O–CaCO3–H2O by FT-IR spectroscopy. Cem Concr Res 31(6):869–872

Mollah M, Yu W, Schennach R, Cocke DL (2000) A Fourier transform infrared spectroscopic investigation of the early hydration of Portland cement and the influence of sodium lignosulfonate. Cem Concr Res 30(2):267–273

Minakshi M, Higley S, Baur C, Mitchell DR, Jones RT, Fichtner M (2019) Calcined chicken eggshell electrode for battery and supercapacitor applications. RSC Adv 9(46):26981–26995

Dayanidhi K, Vadivel P, Jothi S, Eusuff NS (2020) Facile synthesis of Silver@ Eggshell nanocomposite: A heterogeneous catalyst for the removal of heavy metal ions, toxic dyes and microbial contaminants from water. J Environ Manage 271:110962

Ding Q, Kang Z, He X, Wang M, Lin M, Lin H, Yang D-P (2019) Eggshell membrane-templated gold nanoparticles as a flexible SERS substrate for detection of thiabendazole. Microchim Acta 186(7):1–9

Hossain KMA (2006) High strength blended cement concrete incorporating volcanic ash: Performance at high temperatures. Cement Concr Compos 28(6):535–545

Heikal M, El-Didamony H, Sokkary T, Ahmed I (2013) Behavior of composite cement pastes containing microsilica and fly ash at elevated temperature. Constr Build Mater 38:1180–1190

Verdolotti L, Di Maio E, Lavorgna M, Iannace S, Nicolais L (2008) Polyurethane–cement-based foams: Characterization and potential uses. J Appl Polym Sci 107(1):1–8

Li Q, Zhang L, Gao X, Zhang J (2020) Effect of pulverized fuel ash, ground granulated blast-furnace slag and CO2 curing on performance of magnesium oxysulfate cement. Constr Build Mater 230:116990

Yang R, Wang B, Li M, Zhang X, Li J (2019) Preparation, characterization and thermal degradation behavior of rigid polyurethane foam using a malic acid based polyols. Ind Crops Prod 136:121–128

Bouargane B, Biyoune MG, Mabrouk A, Bachar A, Bakiz B, Ahsaine HA, Billah SM, Atbir A (2020) Experimental Investigation of the Effects of Synthesis Parameters on the Precipitation of Calcium Carbonate and Portlandite from Moroccan Phosphogypsum and Pure Gypsum Using Carbonation Route. Waste and Biomass Valorization 1–13

Marcovich N, Kurańska M, Prociak A, Malewska E, Kulpa K (2017) Open cell semi-rigid polyurethane foams synthesized using palm oil-based bio-polyol. Ind Crops Prod 102:88–96

Veronese VB, Menger RK, Forte MMdC, Petzhold CL (2011) Rigid polyurethane foam based on modified vegetable oil. J Appl Polym Sci 120(1):530–537

Zieleniewska M, Leszczyński MK, Kurańska M, Prociak A, Szczepkowski L, Krzyżowska M, Ryszkowska J (2015) Preparation and characterisation of rigid polyurethane foams using a rapeseed oil-based polyol. Ind Crops Prod 74:887–897

Lv S, Hu H, Zhang J, Luo X, Lei Y, Sun L (2017) Fabrication of GO/cement composites by incorporation of few-layered GO nanosheets and characterization of their crystal/chemical structure and properties. Nanomaterials 7(12):457

Palanisamy A, Rao B, Mehazabeen S (2011) Diethanolamides of castor oil as polyols for the development of water-blown polyurethane foam. J Polym Environ 19(3):698–705

Aranberri I, Montes S, Wesołowska E, Rekondo A, Wrześniewska-Tosik K, Grande H-J (2019) Improved Thermal Insulating Properties of Renewable Polyol Based Polyurethane Foams Reinforced with Chicken Feathers. Polymers 11(12):2002

Oprea S (2010) Synthesis and properties of polyurethane elastomers with castor oil as crosslinker. J Am Oil Chem Soc 87(3):313–320

Leng W, Pan B (2019) Thermal Insulating and mechanical properties of cellulose nanofibrils modified polyurethane foam composite as structural insulated material. Forests 10(2):200

Zhang M, Pan H, Zhang L, Hu L, Zhou Y (2014) Study of the mechanical, thermal properties and flame retardancy of rigid polyurethane foams prepared from modified castor-oil-based polyols. Ind Crops Prod 59:135–143

Mosiewicki MA, Dell’Arciprete GA, Aranguren MI, Marcovich NE (2009) Polyurethane foams obtained from castor oil-based polyol and filled with wood flour. J Compos Mater 43(25):3057–3072

Lee J, Jung I (2019) Tuning sound absorbing properties of open cell polyurethane foam by impregnating graphene oxide. Appl Acoust 151:10–21

Ji Y, Chen S, Cheng Y (2019) Synthesis and acoustic study of a new tung oil-based polyurethane composite foam with the addition of miscanthus lutarioriparius. Polymers 11(7):1144

Wang Y, Zhang C, Ren L, Ichchou M, Galland MA, Bareille O (2013) Influences of rice hull in polyurethane foam on its sound absorption characteristics. Polym Compos 34(11):1847–1855

Chen WH, Lee FC FC, Chiang DM (2000) On the acoustic absorption of porous materials with different surface shapes and perforated plates. J Sound Vib 237(2):337–355

Sijia Liu KZ, Cui S, Shen X, Tan G (2018) A novel building material with low thermal conductivity: Rapid synthesis of foam concrete reinforced silica aerogel and energy performance simulation. Energy Build 177:385–393

Campanella A, Bonnaillie L, Wool R (2009) Polyurethane foams from soyoil-based polyols. J Appl Polym Sci 112(4):2567–2578

Modesti M, Lorenzetti A (2003) Improvement on fire behaviour of water blown PIR–PUR foams: Use of an halogen-free flame retardant. Eur Polymer J 39(2):263–268

Bentz D (2007) Transient plane source measurements of the thermal properties of hydrating cement pastes. Mater Struct 40(10):1073–1080

de Almeida Joana FP, Ribeiro Alexandra B, António SS (2021) Cement-based mortars production applying mining residues treated with an electro-based technology and a thermal treatment: Technical and economic effects. Constr Build Mater 280:1224832

Acknowledgements

Prof. Dr. Sonia Zulfiqar is highly thankful to American University in Cairo (AUC) for financial support through STRC mini-grant and research project No. SSE-CHEM-S.Z.-FY19-FY20-FY21-RG(1-19)-2018-Oct-01-17-53-22. Dr. A. A. Maamoun would like to thank the Chemistry lab at Faculty of Engineering at Ain Shams University, Egypt. The authors would like to thank Royal Foam Co. Egypt for their support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mahmoud, A.A., Nasr, E.A., Zulfiqar, S. et al. Fabrication of castor oil-derived polyurethane mortar composites with energy saving and sound absorption characteristics. J Polym Res 28, 483 (2021). https://doi.org/10.1007/s10965-021-02836-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02836-z