Abstract

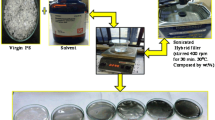

Working with pristine polystyrene is a great challenge due to its poor mechanical properties and is a massive task to utilize for packaging and structural applications. This study includes the analysis and optimization of tensile properties of graphene-polystyrene nanocomposites membrane to determine the reinforcing effect of nanofiller on tensile properties. The two-dimensional (2D) graphene sheets and samples of graphene-polystyrene nanocomposites were fabricated by liquid exfoliation and solution casting technique, respectively. Nanocomposites were characterized by scanning electron microscopy (SEM), X-ray diffraction (XRD), atomic force microscopy (AFM) and thermogravimetric analysis (TGA) to evaluate their morphology, crystallographic phases, topography and thermal stability, respectively. Effect of filler concentration (0.06—0.74 wt. %), sonication time after mixing (3.18 – 36.82 min) and sonication temperature (16.48 – 58.52 ˚C) on ultimate tensile strength (UTS), percentage elongation and elastic modulus (E) were investigated and their responsive behavior was monitored respectively. In our experiment, it is shown that the concentration of graphene is a highly significant parameter. The optimized variables were found to be 0.60 wt. % of Graphene at 10 min of sonication time after mixing and 25 °C of sonication temperature. The obtained results demonstrate that the incorporation of graphene in the polystyrene matrix increases the mechanical properties of polystyrene. When compared with pristine polystyrene, the maximum increase witnessed in UTS, elongation and E was 97.36%, 82.70% and 174.08%, respectively.

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings are available from the corresponding author upon reasonable request.

References

Liu W, Liu L, Liao J, Wang L, Li N (2017) Self-crosslinking of comb-shaped polystyrene anion exchange membranes for alkaline fuel cell application. J Membr Sci 536:133–140

Fakhri LA, Ghanbarzadeh B, Dehghannya J, Abbasi F, Ranjbar H (2018) Optimization of mechanical and color properties of polystyrene/nanoclay/nano ZnO based nanocomposite packaging sheet using response surface methodology. Food Packag Shelf Life 17:11–24

Min J, Zhang S, Li J, Klingeler R, Wen X, Chen X, Zhao X, Tang T, Mijowska E (2019) From polystyrene waste to porous carbon flake and potential application in supercapacitor. Waste Manage 85:333–340

Chanhoun M, Padonou S, Adjovi EC, Olodo E, Doko V (2018) Study of the implementation of waste wood, plastics and polystyrenes for various applications in the building industry. Constr Build Mater 167:936–941

Bukhari MD, Gohar GA, Akhtar A, Ullah S, Akram M, Abid J, Raza HJVAS (2020) Adhesion theories and effect of surface roughness on energy estimation and wettability of polymeric composites bonded joints: A-review 2:74–86

Deka N, Barman J, Kasthuri S, Nutalapati V, Dutta GK (2020) Transforming waste polystyrene foam into N-doped porous carbon for capacitive energy storage and deionization applications. Appl Surf Sci 511:145576

Modigunta JKR, Kim JM, Cao TT, Yabu H (2020) Pore-selective modification of the honeycomb-patterned porous polystyrene film with poly (N-isopropylacrylamide) and application for thermo-responsive smart material. Polymer 122630

Raza H, Aized T, Khan MB, Imran M (2017) Tensile testing of polystyrene graphene 2D nano composite membrane. Int J Adv Manuf Technol 94:4343–4349

Aized T, Khan MB, Raza H, Ilyas M (2017) Production routes, electromechanical properties and potential application of layered nanomaterials and 2D nanopolymeric composites—a review. Int J Adv Manuf Technol 93:3449–3459

Nair KM, Diwan S, Thomas S (1996) Tensile properties of short sisal fiber reinforced polystyrene composites. J Appl Polym Sci 60:1483–1497

Marcourt M, Cassagnau P, Fulchiron R, Rousseaux D, Lhost O, Karam S (2018) High Impact Polystyrene/CNT nanocomposites: Application of volume segregation strategy and behavior under extensional deformation. Polymer 157:156–165

Sheshmani S, Ashori A, Arab Fashapoyeh M (2013) Wood plastic composite using graphene nanoplatelets. Int J Biol Macromol 58:1–6

Arshad MU, Raza H, Khan MB, Hussain A (2020) Synthesis of 2D Molybdenum Disulfide (MoS2) for enhancement of mechanical and electrical properties of polystyrene (PS) polymer. Polym Test 90:106646

Ijaz H, Raza H, Gohar GA, Ullah S, Akhtar A, Imran M (2020) Effect of graphene oxide doped nano coolant on temperature drop across the tube length and effectiveness of car radiator – A CFD study. Thermal Science and Engineering Progress 20:100689

Jyoti J, Arya AK, Chockalingam S, Yadav SK, Subhedar KM, Dhakate SR, Singh BP (2020) Mechanical, electrical and thermal properties of graphene oxide-carbon nanotube/ ABS hybrid polymer nanocomposites. J Polym Res 27:282

Altavilla C, Fedi F, Sorrentino A, Iannace S, Ciambelli P (2014) Polystyrene/MoS2@oleylamine nanocomposites. AIP Conf Proc 1599:194–197

Han W, Bai Y, Liu S, Ge C, Wang L, Ma Z, Yang Y, Zhang X (2017) Enhanced thermal conductivity of commercial polystyrene filled with core-shell structured BN@PS. Compos Part A Appl Sci Manuf 102:218–227

Mohamed M, Lin RC, Kuo SW (2017) Polybenzoxazine/carbon nanotube composites. Advanced and emerging polybenzoxazine science and technology 725–738

Mohamed MG, Hsu KC, Kuo SW (2015) Bifunctional polybenzoxazine nanocomposites containing photo-crosslinkable coumarin units and pyrene units capable of dispersing single-walled carbon nanotubes. Polym Chem 6:2423–2433

Samy MM, Mohamed MG, Kuo SW (2020) Pyrene-functionalized tetraphenylethylene polybenzoxazine for dispersing single-walled carbon nanotubes and energy storage. Compos Sci Technol 199:108360

Mohamed MG, Kuo SW (2019) Functional silica and carbon nanocomposites based on polybenzoxazines. Macromol Chem Phys 220:1800306

Aized T, Imran M, Raza H, Raza MR, Gohar GA, Iqbal A (2017) Effect of nano-filler graphene on nano-composite system of polystyrene-graphene. Int J Adv Manuf Technol 95:3707–3715

Nair PP, George KE, Jayakrishnan N (2017) Studies on mechanical behavior high impact polystyrene/vinyl clay nanocomposites: Comparison betweenin situpolymerization and melt mixing. Polym Compos 38:68–76

Mazhar S, Lawson BP, Stein BD, Pink M, Carini J, Polezhaev A, Vlasov E, Zulfiqar S, Sarwar MI, Bronstein LM (2020) Elastomer based nanocomposites with reduced graphene oxide nanofillers allow for enhanced tensile and electrical properties. J Polym Res 27:105

Ghasemi FA, Ghasemi I, Menbari S, Ayaz M, Ashori A (2016) Optimization of mechanical properties of polypropylene/talc/graphene composites using response surface methodology. Polym Test 53:283–292

Ma J, Zhang Y, Qin C, Ren F, Wang G (2020) Effects of polystyrene sulfonate/graphene and Mn3O4/graphene on property of aluminum (zinc)-air batteries. Int J Hydrogen Energy 45:13025–13034

Mergen ÖB, Umut E, Arda E, Kara S (2020) A comparative study on the AC/DC conductivity, dielectric and optical properties of polystyrene/graphene nanoplatelets (PS/GNP) and multi-walled carbon nanotube (PS/MWCNT) nanocomposites. Polym Test 90:106682

Zhang M, Li Y, Su Z, Wei G (2015) Recent advances in the synthesis and applications of graphene–polymer nanocomposites. Polym Chem 6:6107–6124

Zhao Z, Cai W, Xu Z, Mu X, Ren X, Zou B, Gui Z, Hu Y (2020) Multi-role p-styrene sulfonate assisted electrochemical preparation of functionalized graphene nanosheets for improving fire safety and mechanical property of polystyrene composites. Compos B Eng 181:107544

Hassan T, Salam A, Khan A, Khan SU, Khanzada H, Wasim M, Khan MQ, Kim IS (2021) Functional nanocomposites and their potential applications: A review. J Polym Res 28:36

Kausar A (2020) Technical viewpoint on polystyrene/graphene nanocomposite. J Thermopl Composit Mater 1–15

Wu JY, Lin MN, Wang LD, Zhang T (2014) Photoluminescence of MoS2 prepared by effective grinding-assisted sonication exfoliation. J Nanomater 2014:1–7

Bonaccorso F, Lombardo A, Hasan T, Sun Z, Colombo L, Ferrari AC (2012) Production and processing of graphene and 2d crystals. Mater Today 15:564–589

Liang A, Jiang X, Hong X, Jiang Y, Shao Z, Zhu DJC (2018) Recent developments concerning the dispersion methods and mechanisms of graphene. Coatings 8:33

Aized T, Imran M, Raza H, Raza MR, Gohar GA, Iqbal A (2018) Effect of nano-filler graphene on nano-composite system of polystyrene-graphene. Int J Adv Manuf Technol 95:3707–3715

Al-Sabagh AM, Moustafa YM, Hamdy A, Killa HM, Ghanem RTM, Morsi RE (2018) Preparation and characterization of sulfonated polystyrene/magnetite nanocomposites for organic dye adsorption. Egypt J Pet 27:403–413

Viswanathan K, Ravi T, Boddula R (2019) Synthesis graphene based sensor for strain data and its characterization. Mater Sci Energy Technol 2:203–207

Chieng B, Ibrahim N, Yunus WW (2012) Optimization of tensile strength of poly (lactic acid)/graphene nanocomposites using response surface methodology. Polym Plast Technol Eng 51:791–799

Funding

The authors gratefully acknowledge Higher Education Commission (HEC) Startup Research Grant Program for the approved grant with grant number 2367.

Author information

Authors and Affiliations

Contributions

Yasir Raza: Investigation, Formal analysis, Methodology, Writing-Original Draft Hassan Raza: Conceptualization, Formal analysis, Validation, Arslan Ahmad: Supervision, Conceptualization,Funding acquisition Moinuddin Mohammed Quazi: Formal Analysis, Review Editing Muhammad Abid: Funding acquisition, Resources Monis Raza Kazmi: Supervision. S.M Ashrafur Rahman: Formal analysis, Review-Editing Z.M. Zulfattah: Formal Analysis, Review-Editing I.M. Rizwanul Fattah: Formal analysis, Review-Editing.

Corresponding author

Ethics declarations

Consent of publication

The authors declare that the submitted work is our original work and has not previously been published in full and is not being considered for publication elsewhere.

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Raza, Y., Raza, H., Ahmad, A. et al. Production and investigation of mechanical properties of graphene/polystyrene nano composites. J Polym Res 28, 217 (2021). https://doi.org/10.1007/s10965-021-02560-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02560-8