Abstract

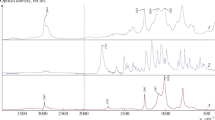

A new class of materials based on crosslinked poly (ester-urethane) containing low proportions of ionic liquid were synthesized using biobased sulfonated oligoester diol, trimethylol propane (TMP), 4,4′-methylene bis(cyclohexyleisocyanate) (HMDI) and 1-butyle-3-methylimidazolium acetate (BMIMAc). Sulfonated oligoester with a well-controlled molar mass was first obtained by melt polycondensation catalyzed by Ti(OBu)4. The resulting products were characterized by, 1HNMR, DSC and MALDI-TOF MS techniques. The systems of crosslinked poly (ester-urethane) and ionic liquid were obtained via a one-shot process. FTIR technical was used for a more effective control of crosslinking reaction. The Thermomechanical analysis of the resulting materials were performed by DSC and DMA technique. Furthermore, the hydrolytic and oxidative degradation study revealed that the degradation of systems mainly depends on the content in ionic liquid and the crosslinking degree of networks.

Similar content being viewed by others

Data availability

The figures used to support the findings of this study are included within the article.

References

Yeganeh H, Hojati-Talemi P (2007) Preparation and properties of novel biodegradable polyurethane networks based on castor oil and poly(ethylene glycol). Polym Deg and Stab 92:480–489. https://doi.org/10.1016/j.polymdegradstab.2006.10.011

Zlatanic A, Petrovic ZS, Dusˇek K (2002) Structure and Properties of Triolein-Based PolyurethaneNetworks. Biomacromolecules 3:1048–1056. https://doi.org/10.1021/bm020046f

Gorna K, Gogolewski S (2002) Biodegradable polyurethanes for implants. II. In vitrodegradation and calcification of materials from poly(ϵ-caprolactone)–poly(ethylene oxide) diols and various chain extenders. J Biomed Mate 60:592–606. https://doi.org/10.1002/jbm.10100

Ilavsk M, Ulmer HW, teNijenhuis TK, Mijs WJ (1994) Effect of Charge Concentration on Dynamic Mechanical, Extraction and Swelling Beha-dour of Polyurethane Networks Based on Triisocyanate and Diethanolamine Derivatives.Polymer gels and Networks 2:73-87. https://doi.org/10.1016/0966-7822(94)90026-4

Miao S, Sun L, Wang P, Liu R, Su Z, Zhang S (2012) Soybean oil-based polyurethane networks as candidate biomaterials: Synthesis and biocompatibility. J Lipid Sci Technol Eur. https://doi.org/10.1002/ejlt.201200050

Ilavsk M, Dusek K (1983) The structure and elasticity of polyurethane networks: 1. Model networks of poly(oxypropylene) triols and diisocyanate. Polymer 24:981–990. https://doi.org/10.1016/0032-3861(83)90148-9

Gorna K, Gogolewski S, Preparation, (2003) degradation, and calcification of biodegradable polyurethane foams for bone graft substitutes. J Biomed Mater Res 67:813–827. https://doi.org/10.1002/jbm.a.10148

Guelcher SA, Patel V, Gallagher KM, Connolly S, Didier JE, Doctor JS, Hollinger JO (2006) Synthesis and In Vitro Biocompatibility of Injectable Polyurethane Foam Scaffolds. Tissue Eng 12:1247–1259. https://doi.org/10.1089/ten.2006.12.1247

Guelcher SA, Srinivasan A, Hafeman AE, Gallagher KM, Doctor JS, Khetan S et al (2007) Synthesis, in vitro degradation, and mechanical properties of two-component poly(ester urethane) urea scaffolds: effects of water and polyol composition. Tissue Eng 13:2321–2333. https://doi.org/10.1089/ten.2006.0395

Navarro-Baena I, Arrieta MP, Sonseca A, Torre L, López D, Giménez E, Kenny JM, Peponi L (2015) Biodegradable nanocomposites based on poly(ester-urethane) and nanosized hydroxyapatite: Plastificant and reinforcement effects. Polym Degrad Stab 121:171–179. https://doi.org/10.1016/j.polymdegradstab.2015.09.002

Feng Y, Li C (2006) Study on oxidative degradation behaviors of poly(ester-urethane) networks. Polym Degrad Stab 91:1711–1716. https://doi.org/10.1016/j.polymdegradstab.2005.12.002

Opera S (2012) Degradation of crosslinked poly(ester-urethanes) Elastomers in Distilled Water: Influence of Hard segment. J Appl Polym Sci 124:1059–1066. https://doi.org/10.1002/app.35196

Storey RF, Wiggins JS, Puckett AD (1994) Hydrolyzable Poly (ester-urethane) Networks from L-Lysine Diisocyanate and D. L-Lactide/e-Caprolactone Homo- and Copolyester Triols, J Polym Sci Part A 31:2345–2363. https://doi.org/10.1002/pola.1994.080321216

Bruin P, Smedinga J, Pennings AJ (1990) Biodegradablley sine djisocyanate-based poly(glycolide-co-&-caprolactone)- urethane network in artificial skin. Biomaterials 11:291–295. https://doi.org/10.1016/0142-9612(90)90013-G

Bruin P, Veenstra GJ, Nijenhuis AJ, Pennings AJ (1988) Design and synthesis of biodegradable poly(ester-urethane) elastomer networks composed of non-toxic building blocks. Makromol Chem 9:589–594. https://doi.org/10.1002/marc.1988.030090814

Storey RF, Wiggins JS, Mauritz KA, Puckett AD (1993) Bioadsorbable composites II: nontoxic, L-lysine-based poly(ester-urethane) matrix composites. Polym Compos 14:17–25. https://doi.org/10.1002/pc.750140104

Guelcher SA, Srinivasan A, Dumas JE, Didier JE, McBride S, Hollinger JO (2008) Synthesis, mechanical properties, biocompatibility, and biodegradation of polyurethane networks from lysine polyisocyanates. Biomaterials 29:1762–1775. https://doi.org/10.1016/j.biomaterials.2007.12.046

Neffe AT, Tronci G, Alteheld A, Lendlein A (2010) Controlled Change of Mechanical Properties during Hydrolytic Degradation of Polyester Urethane Networks. Macromol Phys And Chem 211:182–194. https://doi.org/10.1002/macp.200900441

Zhang Mi, Wang SW, Moore RB, Colby RH, Long TE (2013) Polyurethanes Containing an ImidazoliumDiol‐Based Ionic‐Liquid Chain Extender for Incorporation of Ionic-Liquid Electrolytes. Macromol Chem Phys 214:1027–1036. https://doi.org/10.1002/macp.201200688

Lavall RL, Ferrari S, Tomasi C, Marzantowicz M, Quartaronea E, Magistris A, Mustarelli P, Lazzaroni S, Fagnoni M (2010)Novel polymer electrolytes based on thermoplastic polyurethane and ionic liquid/lithium bis(trifluoromethanesulfonyl)imide/propylene carbonate salt system. J Power Sources 195:5761–5767. https://doi.org/10.1016/j.jpowsour.2010.03.085

Kaar JL, Jesionowski AM, Berberich JA, Moulton R, Russell AJ, Am J (2003) Impact of ionic liquid physical properties on lipase activity and stability. Chem Soc 125:4125–4131. https://doi.org/10.1021/ja028557x

Ngo HL, LeCompte K, Hargens L, McEwen AB (2000) Thermal Properties of Imidazolium Ionic Liquids. Thermochimica Acta 357:97–102. https://doi.org/10.1016/S0040-6031(00)00373-7

Hapiot P, Lagrost C (2008) Electrochemical Reactivity in Room-Temperature Ionic Liquids. Chem Rev 108:2238–2264. https://doi.org/10.1021/cr0680686

Wilkes JS (2002) A short history of ionic liquids—from molten salts to neoteric solvents. Green Chem 4:73–80. https://doi.org/10.1039/B110838G

Berns B, Deligo¨z HS, Tieke B, Kremer F (2008) Conductive Composites of Polyurethane Resins and Ionic Liquids. Macromol Mat And Eng 293:409–418. https://doi.org/10.1002/mame.200700405

Morozova SM, Shaplov AS, Lozinskaya EI, Mecerreyes D, Sardon H, Zulfiqar S, Suarez-Garc ́ía F, Vygodskii YS (2017) Ionic Polyurethanes as a New Family of Poly(ionic liquid)s for Efficient CO2 Capture. Macromolecules 50:2814–2824. https://doi.org/10.1021/acs.macromol.6b02812

Yagci MB, Bolca S, Heuts JPA, Ming W, de With G (2011) Antimicrobial polyurethane coatings based on ionic liquid quaternary ammonium compounds. Prog Org Coat 72:343– 347. https://doi.org/10.1016/j.porgcoat.2011.05.006

Behera PK, Mondal P, Singha NK (2018) Polyurethane by Ionic Liquid Crosslink. A New Class of Super Shape-Memory Like Polymer, Polymer chemistry 9:4205–4217. https://doi.org/10.1039/C8PY00549D

Bougarech A, Abid M, Gouanvé F, Espuche E, Abid S, Gharbi REL, Fleury E (2013) Synthesis, Characterization and Water Sorption Study of New Biobased (Furanic-Sulfonated) Copolyesters. Polymer 54:5482–5489. https://doi.org/10.1016/j.polymer.2013.07.072

Bougarech A, Abid M, DaCruz-Boisson F, Abid S, El Gharbi R, Fleury E (2014)Modulation of furanic-sulfonatedisophthalic copolyesters properties through diols units control. Eur Polym J 58:207–217. https://doi.org/10.1016/j.eurpolymj.2014.06.018

Abid M, Mhiri S, Triki R, Bougarech A, Abid S (2020) Preparation, characterization and degradation study of novel sulfonatedfuranic poly(ester- amide)s. Des Monomers Polym 23:16–24.https://doi.org/10.1080/15685551.2020.1727171

Bougarech A, Abid S, Abid M (2020) Poly (ethylene 2,5-furandicarboxylate) ionomers with enhanced liquid water sorption and oxidative degradation. J Polym Res 27:217. https://doi.org/10.1007/s10965-020-02194-2

Triki R, Bougarech A, Tessier M, Abid S, Fradet A, Abid M (2018) Furanic–Aliphatic Polyesteramides by Bulk Polycondensation Between Furan-Based Diamine, Aliphatic Diester and Diol. J Polym Environ 26:1272–1278. https://doi.org/10.1007/s10924-017-1037-

HadjKacem Y, Bougarech A, Abid S, Abid M, Fleury E (2019) Fullybiobased aliphatic anionic oligoesters: synthesis and properties. Int J Polym Sci. https://doi.org/10.1155/2019/3186202

Pattanayak A, Jana SC (2005) Thermoplastic polyurethane nanocomposites of reactive silicate clays: effects of soft segments on properties. Polymer 46:5183–5193. https://doi.org/10.1016/j.polymer.2005.04.035

Irusta L, Fernandez-Berridi MJ (2000) Aromatic poly (ester–urethanes): effect of the polyol molecular weight on the photochemical behaviour. Polymer 41:3297–3302. https://doi.org/10.1016/S0032-3861(99)00548-0

Hiltz JA, Szabo JP (2001) Ft-irstudy of poly (ether) urethanes. Technical Report DREA-TM-2001–073, Recherche et développement pour la défense Canada 01- 06

Coates J (2006) Interpretation of Infrared Spectra, a Practical Approach, Encyclopedia of analytical chemistry 10815– 10837. https://doi.org/10.1002/9780470027318.a5606

Wilhelm C, Gardette JL (1997) Infrared analysis of the photochemical behaviour of segmented polyurethanes: 1. aliphatic poly (ester-urethane). Polymer 38:4019–4031. https://doi.org/10.1016/S0032-3861(96)00984-6

Maziz A (2014) Microactionneurs à base de polymères conducteurs électroniques : Vers l’intégration aux microsystèmes par de nouveaux procédés d’élaboration. Thèse de doctorat, Laboratoire de physico-chimie des polymères et des interfaces (LPPI)

Pascault J-P, Sautereau H, Verdu J, Williams RJJ (2002) Thermosetting Polymers. Marcel Dekker, New York

El Mahdi A, M’Sahel M, Medimagh R (2017) Catalyst-Free Ring Opening Synthesis of Biodegradable Poly (ester-urethane)s Using Isosorbide Bio-Based Initiator. Macromol Chem Phys 218:1700077. https://doi.org/10.1002/macp.201700077

Liu J, Cao D, Zhang L. (2009) Static and dynamic properties of model elastomer with various cross-linking densities: a molecular dynamics study. J Chem Phys 131:03490. https://doi.org/10.1063/1.3179691

Scott MP, Benton MG, Rahman M, Brazel CS (2003) Ionic Liquids as Green Solvents: Progress and Prospects. ACS Symp Ser 856:468

Scott MP, Brazel CS, Benton MG, Mays JW, Holbrey JD, Rogers RD (2002) Application of ionic liquids as plasticizers for poly(methyl methacrylate). Chem Commun 13:1370–1371. https://doi.org/10.1039/b204316p

Okuzaki H, Takagi S, Hishiki F, Tanigawa R (2014) Ionic liquid/polyurethane/PEDOT:PSS composites for electro-active polymer actuators. Sensors Actuators B Chem 194:59– 63. https://doi.org/10.1016/j.snb.2013.12.059

Bendaoud A, Chalameta Y (2014) Plasticizing effect of ionic liquid on cellulose acetate obtained by melt processing. Carbohydr Polym 108:75–82. https://doi.org/10.1016/j.carbpol.2014.03.023

Chan-Chan LH, Solis-Correa R, Vargas-Coronado RF, Cervantes-Uc JM, Cauich-Rodriguez JV, Quintana P, Batolo-Perez P (2010) Degradation Studies on Segmented Polyurethane Prepared with HMDI, PCL and Different Chain Extenders. Acta Biomater 6:2035–2044. https://doi.org/10.1016/j.actbio.2009.12.010

Lyu S, Schley J, Loy B, Luo L, Hobot C, Sparer R, Untereker D, Krzeszak J (2002) In vitro Biostability Evaluation of Polyurethane Composites in Acidic, Basic, Oxidative, and Neutral Solutions. J Biomed Mater Res B Appl Biomater 58:509 518. https://doi.org/10.1002/jbm.b.30973

Schubert MA, Wiggins MJ, Anderson JM, Hiltner A. (1997) Role of oxygen in biodegradation of poly(etherurethane urea) elastomers. J Biomed Mater 34:519–530. https://doi.org/10.1002/(SICI)1097-4636(19970315)34:4519::AID-JBM123.0.CO;2-7

Acknowledgments

The authors gratefully acknowledge financial support of the Ministry of Higher Education and Scientific Research in Tunisia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors confirm that this article content has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

10965_2021_2491_MOESM1_ESM.docx

Supplementary file1 Supplementary Materials.This is the 1H NMR spectrum of Na-DMSS (SI.1), the table of each MALDI-TOF MS peaks (SI.2), DSC and TGA curves of PBSu70Ss30and PEUR/IL 0–7 (SI.3) and (SI.4).(Supplementary Materials). (DOCX 394 KB)

Rights and permissions

About this article

Cite this article

kacem, Y.H., Bougarech, A., Quintard, G. et al. Sulfonated poly (Ester-Urethane) / ionic liquids systems: synthesis, characterization and properties. J Polym Res 28, 125 (2021). https://doi.org/10.1007/s10965-021-02491-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02491-4