Abstract

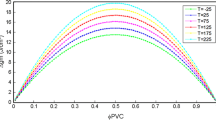

High cut-off (HCO) membranes are the new class of membranes using in several applications like blood purification systems. In the current study, efforts were based upon achieving the HCO membrane with defined properties. Membrane pore collapse is the most challenging problem recognized as an undesirable phenomenon occurring in the drying stage of membrane preparation. Herein, this phenomenon was investigated in detail. The results verified that further of liquid surface tension, other parameters including viscosity, boiling point, polarity, and solubility parameters can be effective on the formation or prevention of this phenomenon. After preventing the pore collapse phenomenon, the simultaneous effect of low and high molecular weights polyvinylpyrrolidone (PVP) to achieve the HCO membrane was evaluated. PVP-K90 is used as a hydrophilizing agent and PVP-K17 is a low molecular weight polymer utilized as a pore-former additive. The synergistic effects of both grades of PVP, provide appropriate membrane features. Contact angle analysis indicated that by incorporation of PVP-K90 in casting solution, membrane hydrophilicity was increased tangibly. With the addition of more content of PVP-K90 higher than 3 wt%, pure water permeability (PWP) of the membrane was decreased. With adding PVP-K17 till 5 wt%, membrane PWP was enhanced significantly which confirmed the pore-former property of this additive. Moreover, mean pore diameter of membranes was increased and subsequently MWCO was enhanced to a higher value with the addition of this pore-former additive. MTT analysis endorsed the biocompatibility of membranes.

Similar content being viewed by others

References

Mazinani S et al (2017) Phase separation analysis of Extem/solvent/non-solvent systems and relation with membrane morphology. J Membr Sci 526:301–314

Barzin J, Sadatnia B (2007) Theoretical phase diagram calculation and membrane morphology evaluation for water/solvent/polyethersulfone systems. Polym 48(6):1620–1631

Shahbabaei M, Kim D (2020) Exploring fast water permeation through aquaporin-mimicking membranes. Phys Chem Chem Phys

Krishnan M et al (1994) Separation of monoclonal IgM antibodies using tangential flow ultrafiltration. Can J Chem Eng 72(6):982–990

Lippi I et al (2015) Double filtration plasmapheresis in a dog with multiple myeloma and hyperviscosity syndrome. Open Vet J 5(2):108–112

Arthanareeswaran G, Mohan D, Raajenthiren M (2010) Preparation, characterization and performance studies of ultrafiltration membranes with polymeric additive. J Membr Sci 350(1–2):130–138

Chakrabarty B, Ghoshal A, Purkait M (2008) Effect of molecular weight of PEG on membrane morphology and transport properties. J Membr Sci 309(1–2):209–221

Weidhase L et al (2019) Middle molecule clearance with high cut-off dialyzer versus high-flux dialyzer using continuous veno-venous hemodialysis with regional citrate anticoagulation: A prospective randomized controlled trial. PLoS ONE 14(4):e0215823

Groopman JD et al (1984) High-affinity monoclonal antibodies for aflatoxins and their application to solid-phase immunoassays. Proc Natl Acad Sci 81(24):7728–7731

Ricci Z, Romagnoli S, Ronco C (2018) High cut-off membranes for continuous renal replacement therapy. In: Annual update in intensive care and emergency medicine, Springer, p. 357–369

Yang Y, Wang P, Zheng Q (2006) Preparation and properties of polysulfone/TiO2 composite ultrafiltration membranes. J Polym Sci Part B Polym Phys 44(5):879–887

Yang M-C, Lin W-C (2002) The grafting of chitosan oligomer to polysulfone membrane via ozone-treatment and its effect on anti-bacterial activity. J Polym Res 9(2):135–140

Chu Z et al (2020) Performance improvement of polyethersulfone ultrafiltration membrane containing variform inorganic nano-additives. Polym 122160

Van der Meeren P et al (2004) Colloid–membrane interaction effects on flux decline during cross-flow ultrafiltration of colloidal silica on semi-ceramic membranes. Phys Chem Chem Phys 6(7):1408–1412

Kim K et al (2002) Surface modification of polysulfone ultrafiltration membrane by oxygen plasma treatment. J Membr Sci 199(1–2):135–145

Ganj M et al (2019) Surface modification of polysulfone ultrafiltration membranes by free radical graft polymerization of acrylic acid using response surface methodology. J Polym Res 26(9):231

Subrahmanyan S (2003) An investigation of pore collapse in asymmetric polysulfone membranes, Virginia Tech

da Silva Burgal J et al (2015) Controlling molecular weight cut-off of PEEK nanofiltration membranes using a drying method. J Membr Sci 493:524–538

Lin C-E et al (2016) Poly (m-phenylene isophthalamide)(PMIA): A potential polymer for breaking through the selectivity-permeability trade-off for ultrafiltration membranes. J Membr Sci 518:72–78

Zverina L et al (2020) Controlled pore collapse to increase solute rejection of modified PES membranes. J Membr Sci 595:117515

Pinnau I, Freeman BD (2000) Formation and modification of polymeric membranes: overview, ACS Publications

Beerlage MA (1994) Polyimide ultrafiltration membranes for non-aqueous systems, Universiteit Twente

Barzin J et al (2018) Improved microfiltration and bacteria removal performance of polyethersulfone membranes prepared by modified vapor-induced phase separation. Polym Adv Technol 29(9):2420–2439

Younas H et al (2019) Fabrication of high flux and fouling resistant membrane: A unique hydrophilic blend of polyvinylidene fluoride/polyethylene glycol/polymethyl methacrylate. Polym 179:121593

Ponnaiyan P, Nammalvar G (2019) Effect of additives on graphene oxide incorporated polysulfone (PSF) membrane. Polym Bull 76(8):4003–4015

Wei YM et al (2005) Polyvinyl alcohol/polysulfone (PVA/PSF) hollow fiber composite membranes for pervaporation separation of ethanol/water solution. J Appl Polym Sci 98(1):247–254

Kim IC, Lee KH (2003) Effect of various additives on pore size of polysulfone membrane by phase-inversion process. J Appl Polym Sci 89(9):2562–2566

Ahmad A, Sarif M, Ismail S (2005) Development of an integrally skinned ultrafiltration membrane for wastewater treatment: effect of different formulations of PSf/NMP/PVP on flux and rejection. Desalination 179(1–3):257–263

Ponnaiyan P, Nammalvar G (2020) Enhanced performance of PSF/PVP polymer membrane by silver incorporation. Polym Bull 77(1):197–212

Liu C et al (2017) Ultrafiltration membranes with tunable morphology and performance prepared by blending quaternized cardo poly (arylene ether sulfone) s ionomers with polysulfone. Sep Purif Technol 179:215–224

Guillen GR et al (2013) Direct microscopic observation of membrane formation by nonsolvent induced phase separation. J Membr Sci 431:212–220

Yoo SH et al (2004) Influence of the addition of PVP on the morphology of asymmetric polyimide phase inversion membranes: effect of PVP molecular weight. J Membr Sci 236(1–2):203–207

Basri H, Ismail AF, Aziz M (2011) Polyethersulfone (PES)–silver composite UF membrane: effect of silver loading and PVP molecular weight on membrane morphology and antibacterial activity. Desalination 273(1):72–80

Barzin J et al (2004a) Effect of polyvinylpyrrolidone on morphology and performance of hemodialysis membranes prepared from polyether sulfone. J Appl Polym Sci 92(6):3804–3813

Pagidi A et al (2014) Enhanced oil–water separation using polysulfone membranes modified with polymeric additives. Desalination 344:280–288

Matsuyama H et al (2003) Effect of PVP additive on porous polysulfone membrane formation by immersion precipitation method. Sep Sci Technol 38(14):3449–3458

Barzin J et al (2004b) Characterization of polyethersulfone hemodialysis membrane by ultrafiltration and atomic force microscopy. J Membr Sci 237(1–2):77–85

Buck, R. and H. Goehl, Perm selective asymmetric hollow fibre membrane for the separation of toxic mediators from blood. 2012, Google Patents.

Mansur S et al (2018) Study on the effect of PVP additive on the performance of PSf/PVP ultrafiltration hollow fiber membrane. Malays J Fundam Appl Sci 14(3):343–347

Mutlu Salmanli Ö et al (2019) Effect of PVP concentration on prepared PEI membranes for potential use on water treatment effect of additive on membranes prepared for water treatment. Water Supply

Boschetti-de-Fierro A et al (2013) Extended characterization of a new class of membranes for blood purification: the high cut-off membranes. Int J Artif Organs 36(7):455–463

Brown GL (1956) Formation of films from polymer dispersions. J Polym Sci 22(102):423–434

Alam J et al (2019) k-Carrageenan–A versatile biopolymer for the preparation of a hydrophilic PVDF composite membrane. Eur Polymer J 120:109219

Bottino A, Capannelli G, Comite A (2002) Preparation and characterization of novel porous PVDF-ZrO2 composite membranes. Desalination 146(1–3):35–40

Zheng Q-Z et al (2006) The relationship between porosity and kinetics parameter of membrane formation in PSF ultrafiltration membrane. J Membr Sci 286(1–2):7–11

He M et al (2016) Antifouling high-flux membranes via surface segregation and phase separation controlled by the synergy of hydrophobic and hydrogen bond interactions. J Membr Sci 520:814–822

Singh S et al (1998) Membrane characterization by solute transport and atomic force microscopy. J Membr Sci 142(1):111–127

Pérez P et al (2013) Corrosion behaviour of Mg–Zn–Y–Mischmetal alloys in phosphate buffer saline solution. Corros Sci 69:226–235

Salimi E et al (2018) Anti-thrombogenicity and permeability of polyethersulfone hollow fiber membrane with sulfonated alginate toward blood purification. Int J Biol Macromol 116:364–377

Zhu L et al (2015) Poly (lactic acid) hemodialysis membranes with poly (lactic acid)-block-poly (2-hydroxyethyl methacrylate) copolymer as additive: preparation, characterization, and performance. ACS Appl Mater Interfaces 7(32):17748–17755

Shahrabi SS, Barzin J, Shokrollahi P (2018) Blood cell separation by novel PET/PVP blend electrospun membranes. Polym Testing 66:94–104

Haidekker M et al (2005) Effects of solvent polarity and solvent viscosity on the fluorescent properties of molecular rotors and related probes. Bioorg Chem 33(6):415–425

Van Oss CJ (2006) Interfacial forces in aqueous media. CRC press

Wolfson A, Dlugy C, Shotland Y (2007) Glycerol as a green solvent for high product yields and selectivities. Environ Chem Lett 5(2):67–71

Gonçalves F et al (2010) PVT, viscosity, and surface tension of ethanol: New measurements and literature data evaluation. J Chem Thermodyn 42(8):1039–1049

Mallevialle J, Odendaal PE, Wiesner MR (1996) Water treatment membrane processes. American Water Works Association

Guillen GR et al (2011) Preparation and characterization of membranes formed by nonsolvent induced phase separation: a review. Ind Eng Chem Res 50(7):3798–3817

Mohsenpour S et al (2016) The role of thermodynamic parameter on membrane morphology based on phase diagram. J Mol Liq 224:776–785

Yang Y et al (2007) The influence of nano-sized TiO2 fillers on the morphologies and properties of PSF UF membrane. J Membr Sci 288(1–2):231–238

Safarpour M et al (2019) Two-stage phase separation of cellulose acetate membranes modified with plasma-treated natural zeolite: Response surface modeling. Polym Adv Technol 30(4):889–901

Ma Y et al (2011) Effect of PEG additive on the morphology and performance of polysulfone ultrafiltration membranes. Desalination 272(1–3):51–58

Zheng Q-Z, Wang P, Yang Y-N (2006) Rheological and thermodynamic variation in polysulfone solution by PEG introduction and its effect on kinetics of membrane formation via phase-inversion process. J Membr Sci 279(1–2):230–237

Lee K-W et al (2003) Trade-off between thermodynamic enhancement and kinetic hindrance during phase inversion in the preparation of polysulfone membranes. Desalination 159(3):289–296

Barzin J, Madaeni SS, Mirzadeh H (2005) Effect of preparation conditions on morphology and performance of hemodialysis membranes prepared from polyether sulphone and polyvinylpyrrolidone

Albrecht W et al (2001) Formation of hollow fiber membranes from poly (ether imide) at wet phase inversion using binary mixtures of solvents for the preparation of the dope. J Membr Sci 192(1–2):217–230

Hasheminasab S, Barzin J, Dehghan R (2020) High-Performance Hemodialysis Membrane: Influence of Polyethylene Glycol and Polyvinylpyrrolidone in the Polyethersulfone Membrane. J Membr Sci Res 6(4):438–448

Irfan M et al (2019) Hemodialysis performance and anticoagulant activities of PVP-k25 and carboxylic-multiwall nanotube composite blended Polyethersulfone membrane. Mater Sci Eng, C 103:109769

Basri H, Ismail A, Aziz M (2009) Effect of PVP addition in the preparation of polyethersulfone (PES)–AgNO3 antibacterial membrane. J Appl Membr Sci Technol 10(1)

Yang Q et al (2008) Pioneering explorations of rooting causes for morphology and performance differences in hollow fiber kidney dialysis membranes spun from linear and hyperbranched polyethersulfone. J Membr Sci 313(1–2):190–198

Yang Q, Chung T-S, Weber M (2009) Microscopic behavior of polyvinylpyrrolidone hydrophilizing agents on phase inversion polyethersulfone hollow fiber membranes for hemofiltration. J Membr Sci 326(2):322–331

Dehghan R, Barzin J (2020) Development of a polysulfone membrane with explicit characteristics for separation of low density lipoprotein from blood plasma. Polym Testing 106438

Dehghan R, Barzin J (2020) Low density lipoprotein (LDL) apheresis from blood plasma via anti-biofouling tuned membrane incorporated with graphene oxide-modified carrageenan. J Membr Sci 118878

Zhang G et al (2016) Ultralow oil-fouling heterogeneous poly (ether sulfone) ultrafiltration membrane via blending with novel amphiphilic fluorinated gradient copolymers. Langmuir 32(5):1380–1388

Zhao H et al (2013) Improving the antifouling property of polysulfone ultrafiltration membrane by incorporation of isocyanate-treated graphene oxide. Phys Chem Chem Phys 15(23):9084–9092

Qin Y (2016) Biocompatibility testing for medical textile products. Medical Textile Materials. In: Qin Y (ed) Woodhead Publishing, Waltham, MA, USA, p 191–201

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Dehghan, R., Barzin, J. High cut-off membrane: evaluation of pore collapse and the synergistic effect of low and high molecular weight polyvinylpyrrolidone. J Polym Res 28, 76 (2021). https://doi.org/10.1007/s10965-021-02429-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02429-w