Abstract

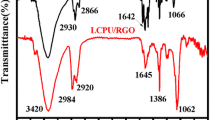

Graphene nanosheets (GNs) often results in incompatibility with the hydrophobic polymer matrix, and the tendency to form aggregates during processing. Herein, hyperbranched polycaprolactone modified GNs (PGNs) was obtained using 3,4,9,10-perylenetetracarboxylic acid anhydride (PTCDA)reacted with GNs and caprolactone. Firstly, π-π stacking interactions between GNs and perylenebisimide derivatives (PBI), and then in-situ polymerization of ε-caprolactone. The structure and characteristic of PGNs were investigated by infrared spectroscopy, wide angle X-ray diffractometry, thermogravimetric analysis and ultraviolet spectrum. PGNs was added into epoxy matrix at different contents to improve the mechanical and thermal properties of epoxy. At 1.0 wt.% PGNs content, the impact strength and tensile strength of PGNs/epoxy composites were 43.41 kJ/m2 and 91.60 MPa. Compared with those of pure epoxy, these value increased by148% and 87%, respectively, as well as the Tg increased by about 20 °C.

Similar content being viewed by others

Change history

10 May 2020

The original version of this article unfortunately contained a mistake. Figure 2 was processed incorrectly. The correct Fig.��2 is now shown here.

References

Zhang X, Alloul O, He Q, Zhu J, Verde MJ, Li Y, Wei S, Guo Z (2013) Strengthened magnetic epoxy nanocomposites with protruding nanoparticles on the graphene nanosheets. Polymer 54:3594–3604

Zhu J, Wei S, Ryu J, Budhathoki M, Liang G, Guo ZJ (2010) Conductive polypyrrole/tungsten oxide metacomposites with negative permittivity. Mater Chem 20:4937–4948

Azeez AA, Rhee KY, Park SJ, Hui D (2013) Epoxy clay nanocomposites – processing, properties and applications: a review. Compos Part B Eng 45:308–320

Cui LJ, Geng HZ, Wang WY, Chen LT, Gao J (2013) Functionalization of multi-wall carbon nanotubes to reduce the coefficient of the friction and improve the wear resistance of multi-wall carbon nanotube/epoxy composites. Carbon 48:277–282

Zaman I, Phan TT, Kuan HC, Meng Q, La LTB, Luong L, Youssf O, Ma J (2011) Epoxy/graphene platelets nanocomposites with two levels of interface strength. Polymer 52:1603–1611

Rafiee MA, Rafiee J, Wang Z, Song H, Yu ZZ, Koratkar N (2009) Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano 3:3884–3890

Lee C, Wei X, Kysar JW, Hone J (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321:385–388

Westervelt RM (2008) Graphene Nanoelectronics. Science 320:324–325

Liang J, Wang Y, Huang Y, Ma Y, Liu Z, Cai J, Zhang C, Gao H, Chen Y (2009) Electromagnetic interference shielding of graphene/epoxy composites. Carbon 47:922–925

Pang H, Chen C, Zhang YC, Ren PG, Yan DX, Li ZM (2011) The effect of electric field, annealing temperature and filler loading on the percolation threshold of polystyrene containing carbon nanotubes and graphene nanosheets. Carbon 49:1980–1988

Song P, Cao Z, Cai Y, Zhao L, Fang Z, Fu S (2011) Fabrication of exfoliated graphene-based polypropylene nanocomposites with enhanced mechanical and thermal properties. Polymer 52:4001–4010

Yan J, Wei T, Shao B, Fan Z, Qian W, Zhang M, Wei F (2010) Preparation of a graphene nanosheet/polyaniline composite with high specific capacitance. Carbon 48:487–493

Qi B, Yuan Z, Lu S, Liu K, Li S, Yang L, Yu J (2014) Mechanical and thermal properties of epoxy composites containing graphene oxide and liquid crystalline epoxy. Fiber Polym 15:326–333

Backes C, Hauke F, Hirsch A (2011) The potential of perylene bisimide derivatives for the solubilization of carbon nanotubes and graphene. Adv Mater 23:2588–2601

Hsiao ST, Ma CCM, Tien HW, Liao WH, Wang YS, Li SM, Huang YC (2013) Using a non-covalent modification to prepare a high electromagnetic interference shielding performance graphene nanosheet/water-borne polyurethane composite. Carbon 60:57–66

Wang Y, Chen X, Zhong Y, Zhu F, Loh KP (2009) Large area, continuous, few-layered graphene as anodes in organic photovoltaic devices. Appl Phys Lett 95:063302–063302-3

Georgakilas V, Otyepka M, Bourlinos AB, Chandra V, Kim N, Kemp KC, Hobza P, Zboril R, Kim KS (2012) Functionalization of graphene: covalent and non-covalent approaches, derivatives and applications. Chem Rev 112:6156–6214

Teng CC, Ma CCM, Lu CH, Yang SY, Lee SH, Hsiao MC, Yen MY, Chiou KC, Lee TM (2011) Thermal conductivity and structure of non-covalent functionalized graphene/epoxy composites. Carbon 49:5107–5116

Wang T, Li M, Gao H, Wu Y (2011) Nanoparticle carriers based on copolymers of poly(ε-caprolactone) and hyperbranched polymers for drug delivery. J Colloid Interf Sci 353:107–115

Lönnberg H, Zhou Q, Rd BH, Teeri TT, Malmström E, Hult A (2006) Grafting of cellulose fibers with poly(epsilon-caprolactone) and poly(L-lactic acid) via ring-opening polymerization. Biomacromolecules 7:2178–2185

Roy D, Semsarilar M, Guthrie JT, Perrier S (2009) Cellulose modification by polymer grafting: a review. Cheminform 40:2046–2064

Labet M, Thielemans W (2009) Synthesis of polycaprolactone: a review. Chem Soc Rev 38:3484–3504

Zhang J, Lin T, Cheung SCP, Wang CH (2012) The effect of carbon nanofibres on self-healing epoxy/poly(ε-caprolactone) blends. Compos Sci Technol 72:1952–1959

Haas U, Thalacker C, Adams J, Fuhrmann J, Riethmüller S, Beginn U, Ziener U, Möller M, Dobrawa R, Würthner F (2003) Fabrication and fluorescence properties of perylene bisimide dye aggregates bound to gold surfaces and nanopatterns. J Mater Chem 13:767–772

Huskić M, Pulko I (2015) The synthesis and characterization of multiarm star-shaped graft copolymers of polycaprolactone and hyperbranched polyester. Eur Polym J 70:384–391

Liu Y, Nguyen J, Steele T, Merkel O, Kissel T (2009) A new synthesis method and degradation of hyper-branched polyethylenimine grafted polycaprolactone block mono-methoxyl poly (ethylene glycol) copolymers (hy-PEI-g-PCL-b-mPEG) as potential DNA delivery vectors. Polymer 50:3895–3904

Johansson M, Malmström E, Jansson A, Hult A (2000) Novel concept for low temperature curing powder coatings based on hyperbranched polyesters. J Coating Technol 72:49–54

Trollsås M, Hawker CJ, Remenar JF, Hedrick JL, Johansson M, Ihre H, Hult A (2015) Highly branched radial block copolymers via dendritic initiation of aliphatic polyesters. J Polym Sci Pol Chem 36:2793–2798

Fang M, Wang K, Lu H, Yang Y, Nutt S (2009) Covalent polymer functionalization of graphene nanosheets and mechanical properties of composites. J Mater Chem 19:7098–7105

Wan YJ, Tang LC, Gong LX, Yan D, Li YB, Wu LB, Jiang JX, Lai GQ (2014) Grafting of epoxy chains onto graphene oxide for epoxy composites with improved mechanical and thermal properties. Carbon 69:467–480

Feng QP, Shen XJ, Yang JP, Fu SY, Mai YW, Friedrich K (2011) Synthesis of epoxy composites with high carbon nanotube loading and effects of tubular and wavy morphology on composite strength and modulus. Polymer 52:6037–6045

Zhang X, He Q, Gu H, Wei S, Guo Z (2013) Polyaniline stabilized barium titanate nanoparticles reinforced epoxy nanocomposites with high dielectric permittivity and reduced flammability. J Mater Chem C 1:2886–2899

Ramanathan T, Abdala AA, Stankovich S, Dikin DA, Herreraalonso M, Piner RD, Adamson DH, Schniepp HC, Chen X, Ruoff RS (2008) Functionalized graphene sheets for polymer nanocomposites. Nat Nanotechnol 3:327–331

Stankovich S, Dikin DA, Dommett GH, Kohlhaas KM, Zimney EJ, Stach EA, Piner RD, Nguyen ST, Ruoff RS (2006) Graphene-based composite materials. Nature 442:282–286

Park YT, Qian Y, Chan C, Suh T, Nejhad MG, Macosko CW, Stein A (2015) Epoxy toughening with low graphene loading. Adv Funct Mater 25:575–585

Zhang Y, Wang Y, Yu J, Chen L, Zhu J, Hu Z (2014) Tuning the interface of graphene platelets/epoxy composites by the covalent grafting of polybenzimidazole. Polymer 55:4990–5000

Acknowledgments

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (51605109, 51763009 and 51463007), the Natural Science Foundation of Guangxi Province, China (2015GXNSFBA139231 2018GXNSFAA281296 and 2018GXNSFBA281052), Guangxi Ministry-Province Jointly-Constructed Cultivation Base for State Key Laboratory of Processing for Non-ferrous Metal and Featured Materials (19-KF-2 and 19-KF-9).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: Figure 2 was processed incorrectly. The correct Figure 2 is now shown here.

Rights and permissions

About this article

Cite this article

Hou, L., Gao, J., Ruan, H. et al. Mechanical and thermal properties of hyperbranched poly(ε-caprolactone) modified graphene/epoxy composites. J Polym Res 27, 32 (2020). https://doi.org/10.1007/s10965-020-2008-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-2008-x