Abstract

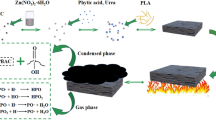

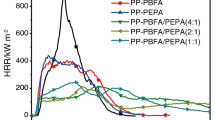

A novel bio-flame retardant (PA-B) was prepared based on green materials--banana peel powder (BPP) and phytic acid (PA), then PA-B was used to prepare flame retardant poly(lactic acid) (PLA) composites. The flame retardancy and thermal property of PLA composites were studied. It can be found that the limiting oxygen index (LOI) of PLA composite with 15.0 wt% BPP is 22.1%, showing the heavy dripping during the combustion and failing to reach the vertical burning tests (UL-94) V-0 rating. However, when 15.0 wt% PA-B is added, the LOI is significantly increased to 37.5%, and the composite can reach UL-94 V-0 rating with the dripping problem is obviously reduced. Furthermore, PA-B is helpful to ameliorate the thermal property of PLA composites under the high temperature. The char residue of PLA/PA-B15 is 10.9 wt% at 550.0 °C, showing much higher value than that of PLA/B15 (3.3 wt%) and pure PLA (almost nothing left). From flammability analysis, PA-B not only is a crucial part of promoting the formation of char layer with high quality in the solid phase, which can play a “barrier effect” role to protect the underlying matrix and retard combustion process, but also has the flame retardant effect in the gaseous phase on the basis of PO· free radical. This work provides an efficient way to prepare bio-based flame retardant PLA composites, and also offers a new method to reuse agricultural wastes like banana peel.

The sketch of eco-friendly flame retardant poly(lactic acid) composites

Similar content being viewed by others

References

Liu HZ, Chen N, Shan PJ, Song PA, Liu XY, Chen JZ (2019) Toward fully bio-based and supertough PLA blends via in situ formation of cross-linked biopolyamide continuity network. Macromolecules 52(21):8415–8429. https://doi.org/10.1021/acs.macromol.9b01398

Zhang T, Yu QY, Fang LL, Wang JJ, Wu T, Song PA (2019) All-organic multilayer coatings for advanced poly(lactic acid) films with high oxygen barrier and excellent antifogging properties. ACS Applied Polymer Materials 1(12):3470–3476. https://doi.org/10.1021/acsapm.9b01030

Cao QM, Meng X, Tan SH, Xin Z, Turng LS, Li J, Yao ZY, Zhai ZH, Duan RZ (2019) Electrospun bead-in-string fibrous membrane prepared from polysilsesquioxane- immobilising poly(lactic acid) with low filtration resistance for air filtration. J Polym Res 27(1):5. https://doi.org/10.1007/s10965-019-1919-x

Xue YJ, Shen MX, Zheng YF, Tao WZ, Han YX, Li WD, Song PA, Wang H (2020) One-pot scalable fabrication of an oligomeric phosphoramide towards high- performance flame retardant polylactic acid with a submicron-grained structure. Compos Pt B-Eng 183:12. https://doi.org/10.1016/j.compositesb.2019.107695

Zong EM, Liu XH, Liu LN, Wang JF, Song PA, Ma ZQ, Ding J, Fu SY (2017) Graft polymerization of acrylic monomers onto lignin with CaCl2-H2O2 as initiator: preparation, mechanism, characterization, and application in poly(lactic acid). ACS Sustain Chem Eng 6(1):337–348. https://doi.org/10.1021/acssuschemeng.7b02599

Shaw SD, Blum A, Weber R, Kannan K, Rich D, Lucas D, Koshland CP, Dobraca D, Hanson S, Birnbaum LS (2010) Halogenated flame retardants: do the fire safety benefits justify the risks? Rev Environ Health 25(4):261–305. https://doi.org/10.1515/REVEH.2010.25.4.261

Yang YX, Haurie L, Wen JH, Zhang SD, Ollivier A, Wang DY (2019) Effect of oxidized wood flour as functional filler on the mechanical, thermal and flame-retardant properties of polylactide biocomposites. Ind Crop Prod 130:301–309. https://doi.org/10.1016/j.indcrop.2018.12.090

Maqsood M, Seide G (2020) Improved thermal processing of polylactic acid/oxidized starch composites and flame-retardant behavior of intumescent non-wovens. Coatings 10(3):20. https://doi.org/10.3390/coatings10030291

Jin XD, Gu XY, Chen C, Tang WF, Li HF, Liu XD, Bourbigot S, Zhang ZW, Sun J, Zhang S (2017) The fire performance of polylactic acid containing a novel intumescent flame retardant and intercalated layered double hydroxides. J Mater Sci 52(20):12235–12250. https://doi.org/10.1007/s10853-017-1354-5

Shan XY, Hu Y, Chen HQ, Yuan XJ (2015) Study on thermal property, flame retardancy and mechanism of poly(lactic acid)/intumescent flame retardant/NiAl layer double hydroxide nanocomposites. Sci Adv Mater 7(9):1848–1857. https://doi.org/10.1166/sam.2015.2418

Yang W, Tawiah B, Yu C, Qian YF, Wang LL, Yuen ACY, Zhu SE, Hu EZ, Chen TBY, Yu B, Lu HD, Yeoh GH, Wang X, Song L, Hu Y (2018) Manufacturing, mechanical and flame retardant properties of poly(lactic acid) biocomposites based on calcium magnesium phytate and carbon nanotubes. Compos Pt A-Appl Sci Manuf 110:227–236. https://doi.org/10.1016/j.compositesa.2018.04.027

Jing J, Zhang Y, Fang ZP, Wang DY (2018) Core-shell flame retardant/graphene oxide hybrid: a self-assembly strategy towards reducing fire hazard and improving toughness of polylactic acid. Compos Sci Technol 165:161–167. https://doi.org/10.1016/j.compscitech.2018.06.024

Wei LL, Wang DY, Chen HB, Chen L, Wang XL, Wang YZ (2011) Effect of a phosphorus-containing flame retardant on the thermal properties and ease of ignition of poly(lactic acid). Polym Degrad Stabil 96(9):1557–1561. https://doi.org/10.1016/j.polymdegradstab.2011.05.018

Zhang Y, Xiong ZQ, Ge HD, Ni LK, Zhang T, Huo SQ, Song PA, Fang ZP (2020) Core-shell bioderived flame retardants based on chitosan/alginate coated ammonia polyphosphate for enhancing flame retardancy of polylactic acid. ACS Sustain Chem Eng 8(16):6402–6412. https://doi.org/10.1021/acssuschemeng.0c00634

Zhang M, Ding XQ, Zhan YX, Wang YT, Wang XL (2020) Improving the flame retardancy of poly(lactic acid) using an efficient ternary hybrid flame retardant by dual modification of graphene oxide with phenylphosphinic acid and nano MOFs. J Hazard Mater 384:13. https://doi.org/10.1016/j.jhazmat.2019.121260

Tawiah B, Yu B, Yuen RKK, Hu Y, Wei RC, Xin JH, Fei B (2019) Highly efficient flame retardant and smoke suppression mechanism of boron modified graphene oxide/poly(lactic acid) nanocomposites. Carbon 150:8–20. https://doi.org/10.1016/j.carbon.2019.05.002

Yin WD, Chen L, Song PA, Dai JF, Meng LH (2018) Mechanically robust, flame-retardant poly(lactic acid) biocomposites via combining cellulose nanofibers and ammonium polyphosphate. ACS Omega 3(5):5615–5626. https://doi.org/10.1021/acsomega.8b00540

Xiong ZQ, Zhang Y, Du XY, Song PA, Fang ZP (2019) Green and scalable fabrication of core-shell biobased flame retardants for reducing flammability of polylactic acid. ACS Sustain Chem Eng 7(9):8954–8963. https://doi.org/10.1021/acssuschemeng.9b01016

Wu CS, Tsou CH (2019) Fabrication, characterization, and application of biocomposites from poly(lactic acid) with renewable rice husk as reinforcement. J Polym Res 26(2):44. https://doi.org/10.1007/s10965-019-1710-z

Reis MO, Olivato JB, Bilck AP, Zanela J, Grossmann MVE, Yamashita F (2018) Biodegradable trays of thermoplastic starch/poly (lactic acid) coated with beeswax. Ind Crop Prod 112:481–487. https://doi.org/10.1016/j.indcrop.2017.12.045

Sun YQ, Ma ZW, Xu XD, Liu XH, Liu LN, Huang GB, Liu L, Wang H, Song PA (2020) Grafting lignin with bioderived polyacrylates for low-cost, ductile, and fully biobased poly(lactic acid) composites. ACS Sustain Chem Eng 8(5):2267–2276. https://doi.org/10.1021/acssuschemeng.9b06593

Shih YF, Chou MY, Chang WC, Lian HY, Chen CM (2017) Completely biodegradable composites reinforced by the cellulose nanofibers of pineapple leaves modified by eco-friendly methods. J Polym res 24 (11):209. https://doi.org/10.1007/s10965-017-1367-4

Akderya T, Özmen U, Baba BO (2020) Investigation of long-term ageing effect on the thermal properties of chicken feather fibre/poly(lactic acid) biocomposites. J Polym Res 27(6). https://doi.org/10.1007/s10965-020-02132-2

Pappu A, Pickering KL, Thakur VK (2019) Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding. Ind Crop Prod 137:260–269. https://doi.org/10.1016/j.indcrop.2019.05.040

Srivastava KR, Singh MK, Mishra PK, Srivastava P (2019) Pretreatment of banana pseudostem fibre for green composite packaging film preparation with polyvinyl alcohol. J Polym Res 26(4):11. https://doi.org/10.1007/s10965-019-1751-3

Banana Link, All about bananas (2014). https://www.bananalink.org.uk/all-about-bananas/. Accessed 9 Mar 2019

Rambo MKD, Schmidt FL, Ferreira MMC (2015) Analysis of the lignocellulosic components of biomass residues for biorefinery opportunities. Talanta 144:696–703. https://doi.org/10.1016/j.talanta.2015.06.045

Emaga TH, Robert C, Ronkart SN, Wathelet B, Paquot M (2008) Dietary fibre components and pectin chemical features of peels during ripening in banana and plantain varieties. Bioresour Technol 99(10):4346–4354. https://doi.org/10.1016/j.biortech.2007.08.030

Tahir MH, Zhao ZL, Ren JM, Rasool T, Naqvi SR (2019) Thermo-kinetics and gaseous product analysis of banana peel pyrolysis for its bioenergy potential. Biomass Bioenergy 122:193–201. https://doi.org/10.1016/j.biombioe.2019.01.009

Kalali EN, Zhang L, Shabestari ME, Croyal J, Wang DY (2019) Flame-retardant wood polymer composites (WPCs) as potential fire safe bio-based materials for building products: preparation, flammability and mechanical properties. Fire Saf J 107:210–216. https://doi.org/10.1016/j.firesaf.2017.11.001

Costes L, Laoutid F, Brohez S, Delvosalle C, Dubois P (2017) Phytic acid-lignin combination: a simple and efficient route for enhancing thermal and flame retardant properties of polylactide. Eur Polym J 94:270–285. https://doi.org/10.1016/j.eurpolymj.2017.07.018

Chen YB, Liu C, Zhang SL, Chen GQ, Xing TL (2018) Combustion properties and thermal decomposition kinetics of flame retardant silk fabrics treated by phytic acid and silica sols. Therm Sci 22(4):1665–1671. https://doi.org/10.2298/tsci1804665c

Gao YY, Deng C, Du YY, Huang SC, Wang YZ (2019) A novel bio-based flame retardant for polypropylene from phytic acid. Polym Degrad Stabil 161:298–308. https://doi.org/10.1016/j.polymdegradstab.2019.02.005

Wang PJ, Liao DJ, Hu XP, Pan N, Li WX, Wang DY, Yao Y (2019) Facile fabrication of biobased P-N-C-containing nano-layered hybrid: preparation, growth mechanism and its efficient fire retardancy in epoxy. Polym Degrad Stabil 159:153–162. https://doi.org/10.1016/j.polymdegradstab.2018.11.024

Cheng XW, Tang RC, Yao F, Yang XH (2019) Flame retardant coating of wool fabric with phytic acid/polyethyleneimine polyelectrolyte complex. Prog Org Coat 132:336–342. https://doi.org/10.1016/j.porgcoat.2019.04.018

Nie SB, Jin D, Yang JN, Dai GL, Luo Y (2019) Fabrication of environmentally-benign flame retardant cotton fabrics with hydrophobicity by a facile chemical modification. Cellulose 26(8):5147–5158. https://doi.org/10.1007/s10570-019-02431-y

Laufer G, Kirkland C, Morgan AB, Grunlan JC (2012) Intumescent multilayer nanocoating, made with renewable polyelectrolytes, for flame-retardant cotton. Biomacromolecules 13(9):2843–2848. https://doi.org/10.1021/bm300873b

Liu LN, Qian MB, Song PA, Huang GB, Yu YM, Fu SY (2016) Fabrication of green lignin-based flame retardants for enhancing the thermal and fire retardancy properties of polypropylene/wood composites. ACS Sustain Chem Eng 4(4):2422–2431. https://doi.org/10.1021/acssuschemeng.6b00112

Pacaphol K, Aht-Ong D (2017) The influences of silanes on interfacial adhesion and surface properties of nanocellulose film coating on glass and aluminum substrates. Surf Coat Technol 320:70–81. https://doi.org/10.1016/j.surfcoat.2017.01.111

Robles E, Csoka L, Labidi J (2018) Effect of reaction conditions on the surface modification of cellulose nanofibrils with aminopropyl triethoxysilane. Coatings 8(4):14. https://doi.org/10.3390/coatings8040139

Chiang CH, Ishida H, Koenig JK (1980) A phosphorus-, nitrogen- and carbon-containing polyelectrolyte complex: preparation,characterization and its flame retardant performance on polypropylene. RSC Adv 4(89):48285–48292. https://doi.org/10.1016/0021-9797(80)90209-X

Manju P, Krishnan PSG, Nayak SK (2020) In-situ polymerised PLA-SEP bionanocomposites: effect of silanol groups on the properties of PLA. J Polym res 27 (5). 0.1007/s10965-020-02098-1

Zhang T, Yan HQ, Shen L, Fang ZP, Zhang XM, Wang JJ, Zhang BY (2014) A phosphorus-, nitrogen- and carbon-containing polyelectrolyte complex: preparation, characterization and its flame retardant performance on polypropylene. RSC Adv 4(89):48285–48292. https://doi.org/10.1039/c4ra09243k

Yu YM, Fu SY, Song PA, Luo XP, Jin YM, Lu FZ, Wu Q, Ye JW (2012) Functionalized lignin by grafting phosphorus-nitrogen improves the thermal stability and flame retardancy of polypropylene. Polym Degrad Stabil 97(4):541–546. https://doi.org/10.1016/j.polymdegradstab.2012.01.020

Feng JB, Sun YQ, Song PA, Lei WW, Wu Q, Liu LN, Yu YM, Wang H (2017) Fire-resistant, strong, and green polymer nanocomposites based on poly(lactic acid) and core-shell nanofibrous flame retardants. ACS Sustain Chem Eng 5(9):7894–7904. https://doi.org/10.1021/acssuschemeng.7b01430

Mandal A, Chakrabarty D (2014) Studies on the mechanical, thermal, morphological and barrier properties of nanocomposites based on poly (vinyl alcohol) and nanocellulose from sugarcane bagasse. J Ind Eng Chem 20(2):462–473. https://doi.org/10.1016/j.jiec.2013.05.003

Yang MQ, Wang F, Zhou SJ, Lu ZS, Ran SY, Li L, Shao JX (2019) Thermal and mechanical performance of unidirectional composites from bamboo fibers with varying volume fractions. Polym Compos 40(10):3929–3937. https://doi.org/10.1002/pc.25253

Ibrahim MM, Dufresne A, El-Zawawy WK, Agblevor FA (2010) Banana fibers and microfibrils as lignocellulosic reinforcements in polymer composites. Carbohydr Polym 81(4):811–819. https://doi.org/10.1016/j.carbpol.2010.03.057

Gao M, Li JF, Zhou X (2019) A flame retardant rigid polyurethane foam system including functionalized graphene oxide. Polym Compos 40:1274–1282. https://doi.org/10.1002/pc.24965

Asaithambi B, Ganesan GS, Kumar SA (2017) Banana/sisal fibers reinforced poly(lactic acid) hybrid biocomposites; influence of chemical modification of BSF towards thermal properties. Polym Compos 38(6):1053–1062. https://doi.org/10.1002/pc.23668

Xu F, Zhong L, Xu Y, Zhang C, Wang P, Zhang FX, Zhang GX (2019) Synthesis of three novel amino acids-based flame retardants with multiple reactive groups for cotton fabrics. Cellulose 26(12):7537–7552. https://doi.org/10.1007/s10570-019-02599-3

Kurayama F, Suzuki S, Oyamada T, Furusawa T, Sato M, Suzuki N (2010) Facile method for preparing organic/inorganic hybrid capsules using amino-functional silane coupling agent in aqueous media. J Colloid Interface Sci 349(1):70–76. https://doi.org/10.1016/j.jcis.2010.05.039

Wang YL, Li ZP, Li YY, Wang JY, Liu X, Song TY, Yang XM, Hao JW (2018) Spray-drying-assisted layer-by-layer assembly of alginate, 3-aminopropyltriethoxysilane, and magnesium hydroxide flame retardant and its catalytic graphitization in ethylene-vinyl acetate resin. ACS Appl Mater Interfaces 10(12):10490–10500. https://doi.org/10.1021/acsami.8b01556

Tawiah B, Yu B, Wei RC, Yuen RKK, Chen W, Xin JH, Fei B (2019) Simultaneous fire safety enhancement and mechanical reinforcement of poly (lactic acid) biocomposites with hexaphenyl (nitrilotris(ethane-2,1-diyl))tris (phosphoramidate). J Hazard Mater 380:10. https://doi.org/10.1016/j.jhazmat.2019.120856

Tawiah B, Yu B, Yuen ACY, Yuen RKK, Xin JH, Fei B (2019) Thermal, crystalline and mechanical properties of flame retarded poly(lactic acid) with a PBO-like small molecule-phenylphosphonic bis(2-aminobenzothiazole). Polym Degrad Stabil 163:76–86. https://doi.org/10.1016/j.polymdegradstab.2019.03.002

Inukai S, Kurokawa N, Hotta A (2020) Mechanical properties of poly(epsilon-caprolactone) composites with electrospun cellulose nanofibers surface modified by 3-aminopropyltriethoxysilane. J Appl Polym Sci:10. https://doi.org/10.1002/app.48599

Nie SB, Liu XL, Dai GL, Yuan SJ, Cai F, Li BX, Hu Y (2012) Investigation on flame retardancy and thermal degradation of flame retardant poly (butylene succinate)/bamboo fiber biocomposites. J Appl Polym Sci 125:485–489. https://doi.org/10.1002/app.36915

Hu X, Yang HY, Jiang YP, He HL, Liu HY, Huang H, Wan CJ (2019) Facile synthesis of a novel transparent hyperbranched phosphorous/nitrogen-containing flame retardant and its application in reducing the fire hazard of epoxy resin. J Hazard Mater 379:11. https://doi.org/10.1016/j.jhazmat.2019.120793

Liang SY, Hemberger P, Neisius NM, Bodi A, Grutzmacher H, Levalois-Grutzmacher J, Gaan S (2015) Elucidating the thermal decomposition of dimethylmethylphosphonate by vacuum ultraviolet (VUV) photoionization: pathways to the PO radical, a key species in flame-retardant mechanisms. Chem Eur J 21(3):1073–1080. https://doi.org/10.1002/chem.201404271

Chen ZQ, Jiang MW, Chen ZW, Chen TT, Yu Y, Jiang JC (2019) Preparation and characterization of a microencapsulated flame retardant and its flame-retardant mechanism in unsaturated polyester resins. Powder Technol 354:71–81. https://doi.org/10.1016/j.powtec.2019.05.077

Phan HTQ, Nguyen BT, Pham LH, Pham CT, Do TVV, Hoang CN, Nguyen NN, Kim J, Hoang D (2019) Excellent fireproof characteristics and high thermal stability of rice husk-filled polyurethane with halogen-free flame retardant. Polymers 11(10):17. https://doi.org/10.3390/polym11101587

Hong HQ, Xiao RJ, Guo QN, Liu H, Zhang H (2019) Quantitively characterizing the chemical composition of tailored bagasse fiber and its effect on the thermal and mechanical properties of polylactic acid-based composites. Polymers 11(10):20. https://doi.org/10.3390/polym11101567

Ran SY, Fang F, Guo ZH, Song PA, Cai YF, Fang ZP, Wang H (2019) Synthesis of decorated graphene with P, N-containing compounds and its flame retardancy and smoke suppression effects on polylactic acid. Compos Pt B-Eng 170:41–50. https://doi.org/10.1016/j.compositesb.2019.04.037

Shang S, Ma X, Yuan BH, Chen GQ, Sun YR, Huang CY, He S, Dai HM, Chen XF (2019) Modification of halloysite nanotubes with supramolecular self-assembly aggregates for reducing smoke release and fire hazard of polypropylene. Compos Pt B-Eng 177:10. https://doi.org/10.1016/j.compositesb.2019.107371

Acknowledgments

The authors deeply appreciate the Provincial Natural Science Foundation of Anhui (1908085 J20,2008085QE269), the National Natural Science Foundation of China (Nos. 51775001), the University Synergy Innovation Program of Anhui Province (GXXT-2019-027), and Leading Talents Project in Colleges and Universities of Anhui Province.

Availability of data and material

Every data and materials exists in this manuscript are available.

Author information

Authors and Affiliations

Contributions

Fan-bei Kong: Experiment, Data Curation, Investigation, Writing-Original draft preparation.

Qi-lin He: Visualization, Writing-Review & Editing.

Wei Peng: Validation, Resources.

Shi-bin Nie: Conceptualization, Methodology, Writing-Review & Editing, Supervision.

Xiang Dong: Validation, Formal analysis.

Ji-nian Yang: Writing-Review & Editing, Funding acquisition.

Corresponding authors

Ethics declarations

Conflicts of interest

No conflict of interest exits in this manuscript.

Code availability

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kong, Fb., He, Ql., Peng, W. et al. Eco-friendly flame retardant poly(lactic acid) composites based on banana peel powders and phytic acid: flame retardancy and thermal property. J Polym Res 27, 204 (2020). https://doi.org/10.1007/s10965-020-02176-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02176-4