Abstract

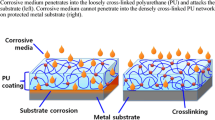

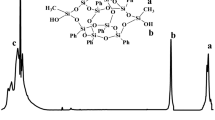

Epoxidation of soybean oil (ESBO) was carried out using Amberlyst 15 catalyst followed by ring opening using bio-based oleic acid to yield polyester polyol (ESOAP). Polyurethane (PU) coating was prepared by utilizing synthesized polyester polyol with hexamethylene diisocyanate (HDI) in the presence of dipentene as a green solvent. To meet industrial standards, biobased polyurethane coatings (Bio-PU) must match the performance of petroleum based polyurethane (Petro-PU) and hence a comparative study is carried out between synthesized bio based polyurethane coating and a petroleum based polyurethane coating. The characterization techniques like Fourier-transform infrared spectroscopy (FT-IR) and Nuclear magnetic resonance (NMR) used for structural elucidation of epoxidized soybean oil and polyester polyol. The cured Bio-PU coating shows good optical and mechanical properties compared to Petro-PU coating. Differential scanning calorimetry (DSC) and Thermo gravimetric analysis (TGA) analysis were carried out to analyse the glass transition temperature (Tg) and thermal stability of the PU coatings. The Electrochemical impendence spectroscopy (EIS) study revealed that the Bio-PU coating exhibited high corrosion resistance (1.23 × 107) against Petro- PU coating. The bio-based content of synthesized polyurethane was calculated to 88.43%. The contribution of oleic acid grants a novel approach to this scheme along with making the end application of coatings more environment friendly.

Similar content being viewed by others

Abbreviations

- SO :

-

Soybean oil

- ESBO :

-

Epoxidized soybean oil

- ESOAP :

-

Epoxidized Soybean oil ring opened with Oleic acid polyol

- PU :

-

Polyurethane

- Bio-PU :

-

Biobased Polyurethane

- Petro-PU :

-

Petroleum based Polyurethane

- MEK :

-

Methyl ethyl ketone

- DBTDL :

-

Dibutyltin dilaurate

- HDI :

-

Hexamethylene diisocyanate

- DSC :

-

Differential scanning calorimetry

- EIS :

-

Electrochemical impendence Spectroscopy

- TGA :

-

Thermo gravimetric analysis

References

Lu Y, Larock RC (2010) Soybean oil-based, aqueous cationic polyurethane dispersions: Synthesis and properties. Prog Org Coat 69:31–37

Akindoyo JO, Beg MDH, Ghazali S, Islam MR, Jeyaratnam N, Yuvaraj AR (2016) Polyurethane types, synthesis and applications – a review. RSC Adv 6:114453–114482

Mahapatra SS, Karak N (2004) Synthesis and characterization of polyesteramide resins from Nahar seed oil for surface coating applications. Prog Org Coat 51:103–108

Sawpan MA (2018) Polyurethanes from vegetable oils and applications: a review. J Polym Res 25:184

Wang C, Zheng Y, Xie Y, Qiao K, Sun Y, Yue L (2015) Synthesis of bio-castor oil polyurethane flexible foams and the influence of biotic component on their performance. J Polym Res 22:145

Saetung N, Somjit S, Thongkapsri P, Tulyapitak T (2016) Modified rubber seed oil based polyurethane foams. J Polym Res 23:58

Panda SS, Panda BP, Nayak SK, Mohanty S (2018) A Review on Waterborne Thermosetting Polyurethane Coatings Based on Castor Oil: Synthesis, Characterization, and Application. J Polym Plast Technol Eng 57:500–522

Desai SD, Emanuel AL, Sinha VK (2003) Biomaterial Based Polyurethane Adhesive for Bonding Rubber and Wood Joints. J Polym Res 10:275–281

Charlon M, Heinrich B, Matter Y, Couzigné E, Donnio B, Avérous L (2014) Synthesis, structure and properties of fully biobased thermoplastic polyurethanes, obtained from a diisocyanate based on modified dimer fatty acids, and different renewable diols. Eur Polym J 61:197–205

Alagi P, Ghorpade R, Hyeon J, Patil C (2018) Functional soybean oil-based polyols as sustainable feedstocks for polyurethane coatings. Ind Crop Prod 113:249–258

Petrovic ZS, Ferguson J (1992). Prog Polym Sci 16:695–836

Ahn BJK, Kraft S, Sun XS (2012) Solvent-Free Acid-Catalyzed Ring-Opening of Epoxidized Oleochemicals Using Stearates/Stearic Acid, and Its Applications. J Agric Food Chem 60:2179–2189

Kalita H, Mandal M, Karak N (2012) Biodegradable solvent-induced shape-memory hyperbranched polyurethane. J Polym Res 19:9982

Somani K, Kansara S, Parmar R, Patel N (2010). Int J Polym Mater 53:283–293

Petrović ZS, Zhang W, Javni I (2005) Structure and Properties of Polyurethanes Prepared from Triglyceride Polyols by Ozonolysis. Biomacromolecules 6:713–719

Garrison TF, Kessler MR, Larock RC (2014) Effects of unsaturation and different ring-opening methods on the properties of vegetable oil-based polyurethane coatings. Polymer 55:1004–1011

Li S, Bouzidi L, Narine SS (2017) Polyols from self-metathesis-generated oligomers of soybean oil and their polyurethane foams. Eur Polym J 93:232–245

Laurichesse S, Huilleta C, Avérous L (2014) Original polyols based on organosolv lignin and fatty acids: new bio-based building blocks for segmented polyurethane synthesis. Green Chem 16:3958–3970

Alagi P, Choi YJ, Hong SC (2016) Preparation of vegetable oil-based polyols with controlled hydroxyl functionalities for thermoplastic polyurethane. Eur Polym J 78:46–60

Prabhudesai MS, Paraskar PM, Kedar R, Kulkarni RD (2020) Sea Buckthorn Oil Tocopherol Extraction's By‐Product Utilization in Green Synthesis of Polyurethane Coating. Eur J Lipid Sci Technol 122(4):1900387

Caillol S, Desroches M, Boutevin G, Loubat C, Auvergne R, Boutevin B (2012) Synthesis of new polyester polyols from epoxidized vegetable oils and biobased acids. Eur J Lipid Sci Technol 114:1447–1459

Thi T, Hoang K, Kim I (2015). Aust J Basic Appl 9:89–93

Goud VV, Pradhan NC, Patwardhan AV (2006) Epoxidation of karanja (Pongamia glabra) oil by H2O2. J Am Oil Chem Soc 83:635–640

Ollevier T, Lavie-compin G (2002) An efficient method for the ring opening of epoxides with aromatic amines catalyzed by bismuth trichloride. Tetrahedron Lett 43:7891–7893

Zhang J, Tang JJ, Zhang JX (2015) Polyols Prepared from Ring-Opening Epoxidized Soybean Oil by a Castor Oil-Based Fatty Diol. Int J of Polym Sci 2015:1–8

Dai H, Yang L, Lin B, Wang C, Shi G (2009) Synthesis and Characterization of the Different Soy-Based Polyols by Ring Opening of Epoxidized Soybean Oil with Methanol, 1,2-Ethanediol and 1,2-Propanediol. J Am Oil Chem Soc 86:261–267

Jacobsen EN, Kakiuchi F, Konsler RG, Larrow JF, Tokunaga M (1997) Enantioselective catalytic ring opening of epoxides with carboxylic acids. Tetrahedron Lett 38:773–776

Tan SG, Chow WS (2010) Biobased Epoxidized Vegetable Oils and Its Greener Epoxy Blends: A Review. Polym-Plast Techno Eng 49:1581–1590

Kulkarni RD, Deshpande PS, Mahajan SU, Mahulikar PP (2013) Epoxidation of mustard oil and ring opening with 2-ethylhexanol for biolubricants with enhanced thermo-oxidative and cold flow characteristics. Ind Crop Prod 49:586–592

Soni S, Agarwal M (2014) Lubricants from renewable energy sources – a review. Green Chem Lett Rev 7:359–382

Sinadinovic-Fiser S (2001) Jankovic´ M, Petrovic ZS. J Am Oil Chem Soc 78:725–731

Rajput SD, Hundiwale DG, Mahulikar PP, Gite VV (2014) Fatty acids based transparent polyurethane films and coatings. Prog Org Coat 77:1360–1368

Kim HJ, Kang MS, Knowles JC, Gong MS (2014) Synthesis of highly elastic biocompatible polyurethanes based on bio-based isosorbide and poly(tetramethylene glycol) and their properties. J Biomater Appl 29(3):454–464

Tavassoli-kafrani MH, De Voort FR Van, Curtis JM (2017) Eur J Lipid Sci Technol 119:1–11

Phalak G, Patil D, Vignesh V, Mhaske S (2018) Development of tri-functional biobased reactive diluent from ricinoleic acid for UV curable coating application. Ind Crop Prod 119:9–21

Pathan S, Ahmad S (2013) Synthesis, characterization and the effect of the s-triazine ring on physico-mechanical and electrochemical corrosion resistance performance of waterborne castor oil alkyd. J Mater Chem A 1:14227–14238

Merdas I, Tcharkhtchi A, Thominette F, Verdu J, Dean K, Cook W (2002) Water absorption by uncrosslinked polymers, networks and IPNs having medium to high polarity. Polymer. 43:4619–4625

Patil DM, Phalak GA, Mhaske ST (2017) Design and synthesis of bio-based UV curable PU acrylate resin from itaconic acid for coating applications. Des Monomers Polym 20:269–282

Kathalewar M, Sabnis A, Melo DD (2014) Polyurethane coatings prepared from CNSL based polyols: Synthesis, characterization and properties. Prog Org Coat 77:616–626

Dong F, Maganty S, Meschter SJ, Cho J (2018) Effects of curing conditions on structural evolution and mechanical properties of UV-curable polyurethane acrylate coatings. Prog Org Coat 114:58–67

Chaudhari A, Gite V, Rajput S, Mahulikar P, Kulkarni R (2013) Development of eco-friendly polyurethane coatings based on neem oil polyetheramide. Ind Crop Prod 50:550–556

Lu F, Song B, He P, Wang J (2017) Electrochemical impedance spectroscopy (EIS) study on the degradation of acrylic polyurethane coatings. RSC Adv 7:13742–13748

Murray JN (1997) Electrochemical test methods for evaluating organic coatings on metals: an update. Part I. Introduction and generalities regarding electrochemical testing of organic coatings. Prog Org Coat 30:225–233

Pan X, Webster DC (2012) New Biobased High Functionality Polyols and Their Use in Polyurethane Coatings. Chem Sus Chem 5:419–429

Acknowledgments

The authors thank the Department of Science and Technology (DST-Inspire), Delhi, India for the funding. The authors also would like to thank Kavayitri Bahinabai Chaudhari, North Maharashtra University Jalgaon for DSC and TGA analysis.

Funding

The authors thank Department of Science and Technology (DST-Inspire), Delhi, India for the funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest/competing interests

There is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(TIF 0.99 mb)

Rights and permissions

About this article

Cite this article

Paraskar, P.M., Prabhudesai, M.S., Deshpande, P.S. et al. Utilization of oleic acid in synthesis of epoxidized soybean oil based green polyurethane coating and its comparative study with petrochemical based polyurethane. J Polym Res 27, 242 (2020). https://doi.org/10.1007/s10965-020-02170-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02170-w