Abstract

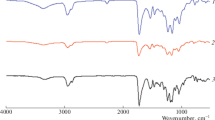

The polyurethane (PU) phase separation could significantly affect its properties. Many factors influence PU phase separation, including soft and hard segments type, their content, and presence of external components such as nanoparticles. The aim of this research was to control the PU phase separation behavior by an internal component which was chemically bonded in PU backbone. For this purpose, a low molecular weight polyester was synthesized and used as a co-soft segment for PU synthesis. The polyester was synthesized by hydroxylation and esterification reaction of unsaturated bonds of raw Canola oil. The PUs were synthesized by two-step polymerization method of poly tetramethyleneglycol (PTMG) and synthesized polyester as soft segments, hexamethylene diisocyanate (HDI), and 1,4 butanediol in 1:3:2 M ratio. In order to study the chemical structure of synthesized materials, specifying the nucleating ability of the synthesized polyol for hard segments, as well as studying its effects on PU properties, different analysis including Fourier Transform Infrared Spectroscopy (FTIR), differential scanning calorimetry (DSC), X-ray diffraction analysis (XRD), Dynamic Mechanical Thermal Analysis (DMTA) and gas permeability were used. Results showed that the presence of the synthesized polyester in the PU structure significantly affects its properties and caused appearance of a new domain for hard segments. These results suggested that polyester polyol can change the PU micro-phase separation by changing hard segments crystalline order.

Similar content being viewed by others

References

Xia L, Li C, Zhang X, Wang J, Wu H, Guo S (2018) Effect of chain length of polyisobutylene oligomers on the molecular motion modes of butyl rubber: damping property. Polymer 141:70–78

Janik H, Marzec M (2015) A review: fabrication of porous PU scaffolds. Mater Sci Eng C 48:586–591

Noreen A, Zia KM, Zuber M, Tabasum S, Zahoor AF (2016) Bio-based PU: an efficient and environment friendly coating systems: a review. Prog Org Coat 91:25–32

Wang X, Hu J, Li Y, Zhang J, Ding Y (2015) The surface properties and corrosion resistance of fluorinated PU coatings. J Fluor Chem 176:14–19

Turan D, Sängerlaub S, Stramm C, Gunes G (2017) Gas permeabilities of PU films for fresh produce packaging: response of O2 permeability to temperature and relative humidity. Polym Test 59:237–244

Wang J, Ye L (2015) Structure and properties of polyvinyl alcohol/PU blends. Compos Part B 69:389–396

Yilgör I, Yilgör E, Wilkes GL (2015) Critical parameters in designing segmented PUs and their effect on morphology and properties: a comprehensive review. Polymer 58:A1–A36

Karimi MB, Khanbabaei G, G. Mir Mohamad Sadeghi, Jafari A (2018). Effect of nano-silica on gas permeation properties of polyether-based PU membrane in the presence of esterified canola oil diol as a nucleation agent for hard segments. J Appl Polym Sci 135

Karimi MB, Hassanajili S (2017) Short fiber/PU composite membrane for gas separation. J Membr Sci 543:40–48

Prisacariu C, Scortanu E, Stoica I, Agapie B, Barboiu V (2011) Morphological features and thermal and mechanical response in segmented PU elastomers based on mixtures of isocyanates. Polym J 43:613

Xing Q, Li R-b, Dong X, Zhang X-q, Zhang L-y, Wang D-j (2015) Phase morphology, crystallization behavior and mechanical properties of poly (L-lactide) toughened with biodegradable PU: effect of composition and hard segment ratio. Chin J Polym Sci 33:1294–1304

Zajac M, Kahl H, Schade B, Rödel T, Dionisio M, Beiner M (2017) Relaxation behavior of PU networks with different composition and crosslinking density. Polymer 111:83–90

Song N, Xin X, Liu H, Xu B, Li B, Li Y, Hou S, Yu Y (2019) Effects of different macrodiols as soft segments on properties of waterborne PU. J Polym Res 26:152

Pedrazzoli D, Manas-Zloczower I (2016) Understanding phase separation and morphology in thermoplastic PUs nanocomposites. Polymer 90:256–263

Korley LTJ, Pate BD, Thomas EL, Hammond PT (2006) Effect of the degree of soft and hard segment ordering on the morphology and mechanical behavior of semicrystalline segmented PUs. Polymer 47:3073–3082

Lee BS, Chun BC, Chung Y-C, Sul KI, Cho JW (2001) Structure and thermomechanical properties of PU block copolymers with shape memory effect. Macromolecules 34:6431–6437

Šebenik U, Krajnc M (2007) Influence of the soft segment length and content on the synthesis and properties of isocyanate-terminated urethane prepolymers. Int J Adhes Adhes 27:527–535

Jafari A, Hassanajili S, Karimi MB, Emami A, Ghaffari F, Azarpira N (2018) Effect of organic/inorganic nanoparticles on performance of PU nanocomposites for potential wound dressing applications. J Mech Behav Biomed Mater

Zhang L, Chen L, Rowan SJ (2017) Trapping dynamic disulfide bonds in the hard segments of thermoplastic PU elastomers. Macromol Chem Physics 218

Terban MW, Dabbous RL, Debellis AD, Pöselt E, Billinge SJ (2016) Structures of Hard Phases in Thermoplastic PUs. Macromolecules 49:7350–7358

Karimi MB, Khanbabaei G, Sadeghi GMM (2017) Vegetable oil-based PU membrane for gas separation. J Membr Sci 527:198–206

Javni I, Bilić O, Bilić N, Petrović ZS, Eastwood EA, Zhang F, Ilavský J (2015) Thermoplastic PUs with controlled morphology based on methylenediphenyldiisocyanate/isosorbide/butanediol hard segments. Polym Int 64:1607–1616

Finnigan B, Martin D, Halley P, Truss R, Campbell K (2004) Morphology and properties of thermoplastic PU nanocomposites incorporating hydrophilic layered silicates. Polymer 45:2249–2260

Imre B, Gojzewski H, Check C, Chartoff R, Vancso GJ (2018) Properties and phase structure of Polycaprolactone-based segmented PUs with varying hard and soft segments: effects of processing conditions. Macromol Chem Phys 219:1700214

Ren N, Song Y, Tao C, Cong B, Cheng Q, Huang Y, Xu G, Bao J (2018) Effect of the soft and hard segment composition on the properties of waterborne PU-based solid polymer electrolyte for lithium ion batteries. J Solid State Electrochem 22:1109–1121

Yildirim E, Yurtsever M, Wilkes G, Yilgör I (2016) Effect of intersegmental interactions on the morphology of segmented PUs with mixed soft segments: a coarse-grained simulation study. Polymer 90:204–214

Merino DH, Feula A, Melia K, Slark AT, Giannakopoulos I, Siviour CR, Buckley CP, Greenland BW, Liu D, Gan Y (2016) A systematic study of the effect of the hard end-group composition on the microphase separation, thermal and mechanical properties of supramolecular PUs. Polymer 107:368–378

Xiao Y, Jiang L, Liu Z, Yuan Y, Yan P, Zhou C, Lei J (2017) Effect of phase separation on the crystallization of soft segments of green waterborne PUs. Polym Test 60:160–165

Sonnenschein MF, Ginzburg VV, Grzesiak AL, Schiller K, Wendt BL (2015) Design, polymerization, and properties of PU elastomers from miscible, immiscible, and hybridized seed-oil derived soft segment blends. J Polym Sci A Polym Chem 53:93–102

Jofre-Reche JA, García-Pacios V, Costa V, Colera M, Martín-Martínez JM (2015) Role of the interactions between carbonate groups on the phase separation and properties of waterborne PU dispersions prepared with copolymers of polycarbonate diol. Prog Org Coat 88:199–211

Gao B, Meng J (2018) High-performance Perovskite solar cells based on the post treatments, advanced science. Eng Med 11:428–432

Gao B, Meng J (2018) High-efficiency polymer solar cells by using co-solvents 1-Chloronaphthalene and 1, 8-Octanedithiol as processing additives. J Electron Mater 47:4016–4021

Pattanayak A, Jana SC (2005) Thermoplastic PU nanocomposites of reactive silicate clays: effects of soft segments on properties. Polymer 46:5183–5193

Yildirim E, Yurtsever M, Yilgör E, Yilgör I, Wilkes GL (2018) Temperature-dependent changes in the hydrogen bonded hard segment network and microphase morphology in a model PU: experimental and simulation studies. J Polym Sci B Polym Phys 56:182–192

Isfahani AP, Ghalei B, Bagheri R, Kinoshita Y, Kitagawa H, Sivaniah E, Sadeghi M (2016) PU gas separation membranes with ethereal bonds in the hard segments. J Membr Sci 513:58–66

Guo Y, Zhang R, Xiao Q, Guo H, Wang Z, Li X, Chen J, Zhu J (2018) Asynchronous fracture of hierarchical microstructures in hard domain of thermoplastic PU elastomer: effect of chain extender. Polymer

Bagdi K, Molnár K, Sajo I, Pukánszky B (2011) Specific interactions, structure and properties in segmented PU elastomers. Express Polym Letters 5

Hezma A, Elashmawi I, Abdelrazek E, Rajeh A, Kamal M (2017) Enhancement of the thermal and mechanical properties of PU/polyvinyl chloride blend by loading single walled carbon nanotubes. Prog Nat Sci: Mater Int 27:338–343

Hosseini-Sianaki T, Nazockdast H, Salehnia B, Nazockdast E (2015) Microphase separation and hard domain assembly in thermoplastic PU/multiwalled carbon nanotube nanocomposites. Polym Eng Sci 55:2163–2173

Saralegi A, Fernandes SC, Alonso-Varona A, Palomares T, Foster EJ, Weder C, Eceiza A, Corcuera MA (2013) Shape-memory bionanocomposites based on chitin nanocrystals and thermoplastic PU with a highly crystalline soft segment. Biomacromolecules 14:4475–4482

Xia H, Song M (2006) Preparation and characterisation of PU grafted single-walled carbon nanotubes and derived PU nanocomposites. J Mater Chem 16:1843–1851

Casper DM, Newbold T (2011) Methods of preparing hydroxy functional vegetable oils, in Google Patents

Petrović ZS (2008) PUs from vegetable oils. Polym Rev 48:109–155

Liang H, Feng Y, Lu J, Liu L, Yang Z, Luo Y, Zhang Y, Zhang C (2018) Bio-based cationic waterborne PUs dispersions prepared from different vegetable oils. Ind Crop Prod 122:448–455

Prociak A, Malewska E, Kurańska M, Bąk S, Budny P (2018) Flexible PU foams synthesized with palm oil-based bio-polyols obtained with the use of different oxirane ring opener. Ind Crop Prod 115:69–77

Sawpan MA (2018) PUs from vegetable oils and applications: a review. J Polym Res 25:184

Alagi P, Choi YJ, Hong SC (2016) Preparation of vegetable oil-based polyols with controlled hydroxyl functionalities for thermoplastic PU. Eur Polym J 78:46–60

Sharma V, Kundu P (2006) Addition polymers from natural oils—a review. Prog Polym Sci 31:983–1008

Mosiewicki M, Casado U, Marcovich N, Aranguren M (2009) PUs from tung oil: polymer characterization and composites. Polym Eng Sci 49:685–692

Datta J, Głowińska E (2014) Effect of hydroxylated soybean oil and bio-based propanediol on the structure and thermal properties of synthesized bio-PUs. Ind Crop Prod 61:84–91

Sadeghi M, Semsarzadeh MA, Barikani M, Chenar MP (2011) Gas separation properties of polyether-based PU–silica nanocomposite membranes. J Membr Sci 376:188–195

Hassanajili S, Masoudi E, Karimi G, Khademi M (2013) Mixed matrix membranes based on polyetherurethane and polyesterurethane containing silica nanoparticles for separation of CO2/CH4 gases. Sep Purif Technol 116:1–12

Saralegi A, Rueda L, Fernández-d'Arlas B, Mondragon I, Eceiza A, Corcuera MA (2013) Thermoplastic PUs from renewable resources: effect of soft segment chemical structure and molecular weight on morphology and final properties. Polym Int 62:106–115

Pichon PG, David L (1888-1900) F.o. Méchin, H. Sautereau, morphologies of cross-linked segmented PUs. Evolution during maturation and consequences on elastic properties and thermal compressive fatigue. Macromolecules 43(2010)

Khosravi A, Sadeghi M, Banadkohi HZ, Talakesh MM (2014) PU-silica nanocomposite membranes for separation of propane/methane and ethane/methane. Ind Eng Chem Res 53:2011–2021

Taheri S, Sadeghi GMM (2015) Microstructure–property relationships of organo-montmorillonite/PU nanocomposites: influence of hard segment content. Appl Clay Sci 114:430–439

Bussu G, Lazzeri A (2006) On the use of dynamic mechanical thermal analysis (DMTA) for measuring glass transition temperature of polymer matrix fibre reinforced composites. J Mater Sci 41:6072–6076

Karimi MB, Hassanajili S, Khanbabei G (2019) Capillary condensation mechanism for gas transport in fiber reinforced poly (ether-b-amide) membranes. Chem Eng Res Des

Ruvolo-Filho A, De Carvalho G (1996) Correlation between crystallinity, sorption properties, and some infrared bands in the spectra of poly (ethylene terephthalate) films. J Macromol Sci Part B: Physics 35:255–264

Wang Y, Gupta M, Schiraldi DA (2012) Oxygen permeability in thermoplastic PUs. J Polym Sci B Polym Phys 50:681–693

Nyflött Å, Meriçer Ç, Minelli M, Moons E, Järnström L, Lestelius M, Baschetti MG (2017) The influence of moisture content on the polymer structure of polyvinyl alcohol in dispersion barrier coatings and its effect on the mass transport of oxygen. J Coat Technol Res 14:1345–1355

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Karimi, M.B., Khanbabaei, G. & Sadeghi, G.M.M. Unsaturated canola oil-based polyol as effective nucleating agent for polyurethane hard segments. J Polym Res 26, 253 (2019). https://doi.org/10.1007/s10965-019-1924-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1924-0