Abstract

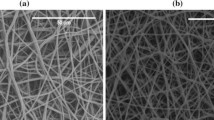

Cardiovascular diseases (CVD) because of blood vessel disease are considered as one of the most frequent causes for mortality in all over the world. Recently, blood vessel tissue engineering is identified as one the promising strategies in order to overcome CVD. Accordingly, using Nano technology provides many benefits in blood vessel tissue engineering. In Present research Unique electrical, mechanical and biochemical properties of SWNT combined with electrospun polyurethane nanofiber was investigated as a functional composite scaffold for vascular tissue engineering. SWNT and polyurethane nanofibers incorporation indicated a biomechanical behavior similar to native artery. The scaffold morphological properties have been investigated by the use of scanning electron microscopy. With respect to the results, nanofiber diameter distribution was narrowed down by increasing SWNT content, while mean nanofiber diameter increased from 40 nm up to 140 nm. Physico-chemical characterization using FTIR, DSC, XRD and Raman test, demonstrated the nanoparticle appropriate dispersion and interaction to the polyurethane macromolecule. Along with increasing SWNT content up to the 2% (W/W) ultimate stress and young modulus increased 3 and 11 time, compared to pure PU, respectively. Structures electrical conductivity was increased from 0.0013 s/cm to 0.36 s/cm along with the increasing of SWNT content up to 2%. SWNT unique properties modulated samples hydrophilicity, and also contact angle of nanofiber scaffolds decreased from 1000 to 770. By passing 7 days, in vitro cell culture demonstrated dense layer of endothelial cells, which is crucial for blood vessel tissue engineering. Obtained results confirmed that electrospun poly urethane-SWNT scaffold could be considered as an appropriate candidate for blood vessel tissue engineering.

Similar content being viewed by others

References

Gaziano TA, Opie LH, Weinstein MC (2006) Cardiovascular disease prevention with a multidrug regimen in the developing world: a cost-effectiveness analysis. Lancet 368(9536):679–686

Chaudhuri R, Ramachandran M, Moharil P, Harumalani M, Jaiswal AK (2017) Biomaterials and cells for cardiac tissue engineering: current choices. Mater Sci Eng C 79:950–957

Innocente F, Mandracchia D, Pektok E, Nottelet B, Tille J-C, De Valence S, Faggian G, Mazzucco A, Kalangos A, Gurny R (2009) Paclitaxel-eluting biodegradable synthetic vascular prostheses: a step towards reduction of neointima formation? Circulation 120(11 suppl 1):S37–S45

Ravi S, Qu Z, Chaikof EL (2009) Polymeric materials for tissue engineering of arterial substitutes. Cardiovasc Eng 17(1_suppl):45–54

Kumar VA, Brewster LP, Caves JM, Chaikof EL (2011) Tissue engineering of blood vessels: functional requirements, progress, and future challenges. Cardiovasc Eng Technol 2(3):137–148

Schmedlen RH, Elbjeirami WM, Gobin AS, West JL (2003) Tissue engineered small-diameter vascular grafts. Clin Plast Surg 30(4):507–517

Shalumon K, Deepthi S, Anupama M, Nair S, Jayakumar R, Chennazhi K (2015) Fabrication of poly (l-lactic acid)/gelatin composite tubular scaffolds for vascular tissue engineering. Int J Biol Macromol 72:1048–1055

Xu C, Inai R, Kotaki M, Ramakrishna S (2004) Aligned biodegradable nanofibrous structure: a potential scaffold for blood vessel engineering. Biomaterials 25(5):877–886

Prabhakaran MP, Venugopal J, Kai D, Ramakrishna S (2011) Biomimetic material strategies for cardiac tissue engineering. Mater Sci Eng C 31(3):503–513

Jing X, Mi H-Y, Salick MR, Cordie TM, Peng X-F, Turng L-S (2015) Electrospinning thermoplastic polyurethane/graphene oxide scaffolds for small diameter vascular graft applications. Mater Sci Eng C 49:40–50

Kucinska-Lipka J, Gubanska I, Janik H, Sienkiewicz M (2015) Fabrication of polyurethane and polyurethane based composite fibres by the electrospinning technique for soft tissue engineering of cardiovascular system. Mater Sci Eng C 46:166–176

Lanza R, Langer R, Vacanti JP (2011) Principles of tissue engineering. Academic press, Cambridge

Sadeghi A, Moztarzadeh F, Mohandesi JA (2019) Investigating the effect of chitosan on hydrophilicity and bioactivity of conductive electrospun composite scaffold for neural tissue engineering. Int J Biol Macromol 121:625–632

O'brien FJ (2011) Biomaterials & scaffolds for tissue engineering. Mater Today 14(3):88–95

Carleton JB, Rodin GJ, Sacks MS (2017) Layered elastomeric fibrous scaffolds: An in-Silico study of the achievable range of mechanical behaviors. ACS Biomater Sci Eng 3(11):2907–2921

Xiang P, Li M, Zhang C-Y, Chen D-L, Zhou Z-H (2011) Cytocompatibility of electrospun nanofiber tubular scaffolds for small diameter tissue engineering blood vessels. Int J Biol Macromol 49(3):281–288

Wang C, Wang M (2014) Electrospun multifunctional tissue engineering scaffolds. Front Mater Sci 8(1):3–19

Ercolani E, Del Gaudio C, Bianco A (2015) Vascular tissue engineering of small-diameter blood vessels: reviewing the electrospinning approach. J Tissue Eng Regen Med 9(8):861–888

Zong H, Xia X, Liang Y, Dai S, Alsaedi A, Hayat T, Kong F, Pan JH (2017) Designing function-oriented artificial nanomaterials and membranes via electrospinning and electrospraying techniques. Mater Sci Eng 92:1075–91

Pan X, Sun B, Mo X (2018) Electrospun polypyrrole-coated polycaprolactone nanoyarn nerve guidance conduits for nerve tissue engineering. Front Mater Sci 12(4):438–446

Bergmeister H, Grasl C, Walter I, Plasenzotti R, Stoiber M, Schreiber C, Losert U, Weigel G, Schima H (2012) Electrospun small-diameter polyurethane vascular grafts: ingrowth and differentiation of vascular-specific host cells. Artif Organs 36(1):54–61

Jaganathan SK, Mani MP, Palaniappan SK, Rathanasamy R (2018) Fabrication and characterisation of nanofibrous polyurethane scaffold incorporated with corn and neem oil using single stage electrospinning technique for bone tissue engineering applications. J Polym Res 25(7):146

Ma D-W, Zhu R, Wang Y-Y, Zhang Z-R, Wang X-Y (2015) Evaluation on biocompatibility of biomedical polyurethanes with different hard segment contents. Front Mater Sci 9(4):397–404

Haghjooy Javanmard S, Anari J, Zargar Kharazi A, Vatankhah E (2016) In vitro hemocompatibility and cytocompatibility of a three-layered vascular scaffold fabricated by sequential electrospinning of PCL, collagen, and PLLA nanofibers. J Biomater Appl 31(3):438–449

Bui HT, Friederich AR, Li E, Prawel DA, James SP (2018) Hyaluronan enhancement of expanded polytetrafluoroethylene cardiovascular grafts. J Biomater Appl: 0885328218776807

Nieponice A, Soletti L, Guan J, Deasy BM, Huard J, Wagner WR, Vorp DA (2008) Development of a tissue-engineered vascular graft combining a biodegradable scaffold, muscle-derived stem cells and a rotational vacuum seeding technique. Biomaterials 29(7):825–833

Naebe M, Lin T, Staiger MP, Dai L, Wang X (2008) Electrospun single-walled carbon nanotube/polyvinyl alcohol composite nanofibers: structure–property relationships. Nanotechnology 19(30):305702

Hanumansetty S, O’Rear E, Resasco DE (2017) Encapsulation of multi-walled carbon nanotubes with copolymer to disperse in aqueous media. J Polym Res 24(12):228

Vigolo B, Penicaud A, Coulon C, Sauder C, Pailler R, Journet C, Bernier P, Poulin P (2000) Macroscopic fibers and ribbons of oriented carbon nanotubes. Science 290(5495):1331–1334

Dalton AB, Collins S, Munoz E, Razal JM, Ebron VH, Ferraris JP, Coleman JN, Kim BG, Baughman RH (2003) Super-tough carbon-nanotube fibres. Nature 423(6941):703

Ghane N, Mazinani S, Gharehaghaji AA (2018) Fabrication and characterization of hollow nanofibrous PA6 yarn reinforced with CNTs. J Polym Res 25(3):80

Zhang Y, Bai Y, Yan B (2010) Functionalized carbon nanotubes for potential medicinal applications. Drug Discov Today 15(11–12):428–435

Sheikhpour M, Golbabaie A, Kasaeian A (2017) Carbon nanotubes: a review of novel strategies for cancer diagnosis and treatment. Mater Sci Eng C 76:1289–1304

Mazinani S, Ajji A, Dubois C (2009) Morphology, structure and properties of conductive PS/CNT nanocomposite electrospun mat. Polymer 50(14):3329–3342

Türk S, Altınsoy I, Efe GÇ, Ipek M, Özacar M, Bindal C (2018) 3D porous collagen/functionalized multiwalled carbon nanotube/chitosan/hydroxyapatite composite scaffolds for bone tissue engineering. Mater Sci Eng C 92:757–768

Zhang H (2011) Effects of electrospinning parameters on morphology and diameter of electrospun PLGA/MWNTs fibers and cytocompatibility in vitro. J Bioact Compat Polym 26(6):590–606

Liu LQ, Tasis D, Prato M, Wagner HD (2007) Tensile mechanics of electrospun multiwalled nanotube/poly (methyl methacrylate) nanofibers. Adv Mater 19(9):1228–1233

Meng J, Kong H, Xu H, Song L, Wang C, Xie S (2005) Improving the blood compatibility of polyurethane using carbon nanotubes as fillers and its implications to cardiovascular surgery. J Biomed Mater Res Part A 74(2):208–214

Zhijiang C, Cong Z, Jie G, Qing Z, Kongyin Z (2018) Electrospun carboxyl multi-walled carbon nanotubes grafted polyhydroxybutyrate composite nanofibers membrane scaffolds: preparation, characterization and cytocompatibility. Mater Sci Eng C 82:29–40

Sahoo NG, Jung YC, Yoo HJ, Cho JW (2006) Effect of functionalized carbon nanotubes on molecular interaction and properties of polyurethane composites. Macromol Chem Phys 207(19):1773–1780

Hotaling NA, Bharti K, Kriel H, Simon CG (2015) DiameterJ: a validated open source nanofiber diameter measurement tool. Biomaterials 61:327–338

Pauly HM, Kelly DJ, Popat KC, Trujillo NA, Dunne NJ, McCarthy HO, Donahue TLH (2016) Mechanical properties and cellular response of novel electrospun nanofibers for ligament tissue engineering: effects of orientation and geometry. J Mech Behav Biomed Mater 61:258–270

Marvizadeh MM, Oladzadabbasabadi N, Nafchi AM, Jokar M (2017) Preparation and characterization of bionanocomposite film based on tapioca starch/bovine gelatin/nanorod zinc oxide. Int J Biol Macromol 99:1–7

Ku SH, Park CB (2010) Human endothelial cell growth on mussel-inspired nanofiber scaffold for vascular tissue engineering. Biomaterials 31(36):9431–9437

Darbandi SMA, Nouri M, Mokhtari J (2012) Electrospun nanostructures based on polyurethane/MWCNTs for strain sensing applications. Fibers Polymers 13(9):1126–1131

Unnithan AR, Gnanasekaran G, Sathishkumar Y, Lee YS, Kim CS (2014) Electrospun antibacterial polyurethane–cellulose acetate–zein composite mats for wound dressing. Carbohydr Polym 102:884–892

Shor L, Güçeri S, Wen X, Gandhi M, Sun W (2007) Fabrication of three-dimensional polycaprolactone/hydroxyapatite tissue scaffolds and osteoblast-scaffold interactions in vitro. Biomaterials 28(35):5291–5297

Nasouri K, Shoushtari AM, Kaflou A, Bahrambeygi H, Rabbi A (2012) Single-wall carbon nanotubes dispersion behavior and its effects on the morphological and mechanical properties of the electrospun nanofibers. Polym Compos 33(11):1951–1959

Tamburaci S, Tihminlioglu F (2018) Biosilica incorporated 3D porous scaffolds for bone tissue engineering applications. Mater Sci Eng C 91:274–291

Veleva A, Heath D, Johnson J, Nam J, Patterson C, Lannutti J, Cooper S (2009) Interactions between endothelial cells and electrospun methacrylic terpolymer fibers for engineered vascular replacements. J Biomed Mater Res Part A 91(4):1131–1139

Weisbecker H, Unterberger MJ, Holzapfel GA (2015) Constitutive modelling of arteries considering fibre recruitment and three-dimensional fibre distribution. J R Soc Interface 12(105):20150111

Ma W, Liu L, Zhang Z, Yang R, Liu G, Zhang T, An X, Yi X, Ren Y, Niu Z (2009) High-strength composite fibers: realizing true potential of carbon nanotubes in polymer matrix through continuous reticulate architecture and molecular level couplings. Nano Lett 9(8):2855–2861

Hatui G, Das CK (2013) Modification of CNT and its effect on thermo mechanical, morphological as well as rheological properties of polyether imide (PEI)/liquid crystalline polymer (LCP) blend system. J Polym Res 20(2):77

Tijing LD, Park C-H, Choi WL, Ruelo MTG, Amarjargal A, Pant HR, Im I-T, Kim CS (2013) Characterization and mechanical performance comparison of multiwalled carbon nanotube/polyurethane composites fabricated by electrospinning and solution casting. Compos Part B 44(1):613–619

Verdejo R, Jell G, Safinia L, Bismarck A, Stevens MM, Shaffer MS (2009) Reactive polyurethane carbon nanotube foams and their interactions with osteoblasts. J Biomed Mater Res A 88(1):65–73

Sirivisoot S, Harrison BS (2011) Skeletal myotube formation enhanced by electrospun polyurethane carbon nanotube scaffolds. Int J Nanomedicine 6:2483

Wang H, Wang E, Liu Z, Gao D, Yuan R, Sun L, Zhu Y (2015) A novel carbon nanotubes reinforced superhydrophobic and superoleophilic polyurethane sponge for selective oil–water separation through a chemical fabrication. J Mater Chem A 3(1):266–273

Barick AK, Tripathy DK (2011) Preparation, characterization and properties of acid functionalized multi-walled carbon nanotube reinforced thermoplastic polyurethane nanocomposites. Mater Sci Eng B 176(18):1435–1447

Lu P, Hsieh Y-L (2010) Multiwalled carbon nanotube (MWCNT) reinforced cellulose fibers by electrospinning. ACS Appl Mater Interfaces 2(8):2413–2420

Jung YC, Kim HH, Kim YA, Kim JH, Cho JW, Endo M, Dresselhaus MS (2010) Optically active multi-walled carbon nanotubes for transparent, conductive memory-shape polyurethane film. Macromolecules 43(14):6106–6112

Sadek E, El-Nashar D, Ward A, Ahmed S (2018) Study on the properties of multi-walled carbon nanotubes reinforced poly (vinyl alcohol) composites. J Polym Res 25(12):249

Saligheh O, Forouharshad M, Arasteh R, Eslami-Farsani R, Khajavi R, Roudbari BY (2013) The effect of multi-walled carbon nanotubes on morphology, crystallinity and mechanical properties of PBT/MWCNT composite nanofibers. J Polym Res 20(2):65

Ouyang Z, Li J, Wang J, Li Q, Ni T, Zhang X, Wang H, Li Q, Su Z, Wei G (2013) Fabrication, characterization and sensor application of electrospun polyurethane nanofibers filled with carbon nanotubes and silver nanoparticles. J Mater Chem B 1(18):2415–2424

Askari F, Barikani M, Barmar M, Shokrollahi P (2017) Polyurethane/amino-grafted multiwalled carbon nanotube nanocomposites: microstructure, thermal, mechanical, and rheological properties. J Appl Polym Sci 134(4)

Bokobza L, Zhang (2012) Raman spectroscopic characterization of multiwall carbon nanotubes and of composites. Express Polym Lett 6 (7)

Heidari M, Bahrami H, Ranjbar-Mohammadi M (2017) Fabrication, optimization and characterization of electrospun poly (caprolactone)/gelatin/graphene nanofibrous mats. Mater Sci Eng C 78:218–229

Tian L, Prabhakaran MP, Hu J, Chen M, Besenbacher F, Ramakrishna S (2016) Synergistic effect of topography, surface chemistry and conductivity of the electrospun nanofibrous scaffold on cellular response of PC12 cells. Colloids Surf B: Biointerfaces 145:420–429

Lu X, Qiu Z, Wan Y, Hu Z, Zhao Y (2010) Preparation and characterization of conducting polycaprolactone/chitosan/polypyrrole composites. Compos Part A 41(10):1516–1523

Liao H, Qi R, Shen M, Cao X, Guo R, Zhang Y, Shi X (2011) Improved cellular response on multiwalled carbon nanotube-incorporated electrospun polyvinyl alcohol/chitosan nanofibrous scaffolds. Colloids Surf B: Biointerfaces 84(2):528–535

Shamosi A, Mehrabani D, Azami M, Ebrahimi-Barough S, Siavashi V, Ghanbari H, Sharifi E, Roozafzoon R, Ai J (2017) Differentiation of human endometrial stem cells into endothelial-like cells on gelatin/chitosan/bioglass nanofibrous scaffolds. Artificial Cells Nanomed Biotechnol 45(1):163–173

Jamadi ES, Ghasemi-Mobarakeh L, Morshed M, Sadeghi M, Prabhakaran MP, Ramakrishna S (2016) Synthesis of polyester urethane urea and fabrication of elastomeric nanofibrous scaffolds for myocardial regeneration. Mater Sci Eng C 63:106–116

Zhang Y, Yu Y, Dolati F, Ozbolat IT (2014) Effect of multiwall carbon nanotube reinforcement on coaxially extruded cellular vascular conduits. Mater Sci Eng C 39:126–133

Tonelli FM, Santos AK, Gomes KN, Lorencon E, Guatimosim S, Ladeira LO, Resende RR (2012) Carbon nanotube interaction with extracellular matrix proteins producing scaffolds for tissue engineering. Int J Nanomedicine 7:4511

Ma J, Wang J-N, Tsai C-J, Nussinov R, Ma B (2010) Diameters of single-walled carbon nanotubes (SWCNTs) and related nanochemistry and nanobiology. Front Mater Sci China 4(1):17–28

Hajiali H, Shahgasempour S, Naimi-Jamal MR, Peirovi H, JIjon (2011) Electrospun PGA/gelatin nanofibrous scaffolds and their potential application in vascular tissue engineering. Int J Nanomedicine 6:2133

Sahithi K, Swetha M, Ramasamy K, Srinivasan N, Selvamurugan N (2010) Polymeric composites containing carbon nanotubes for bone tissue engineering. Int J Biol Macromol 46(3):281–283

Holt I, Gestmann I, Wright AC (2013) Alignment of muscle precursor cells on the vertical edges of thick carbon nanotube films. Mater Sci Eng C 33(7):4274–4279

Fraczek-Szczypta A, Menaszek E, Blazewicz S, Adu J, Shevchenko R, Syeda TB, Misra A, Alavijeh M (2015) Influence of different types of carbon nanotubes on muscle cell response. Mater Sci Eng C 46:218–225

Eyni H, Ghorbani S, Shirazi R, Salari Asl L, Beiranvand PS, Soleimani M (2017) Three-dimensional wet-electrospun poly (lactic acid)/multi-wall carbon nanotubes scaffold induces differentiation of human menstrual blood-derived stem cells into germ-like cells. J Biomater Appl 32(3):373–383

Ko Y-G, Park JH, Lee JB, Oh HH, Park WH, Cho D, Kwon OH (2016) Growth behavior of endothelial cells according to electrospun poly (D, L-lactic-co-glycolic acid) fiber diameter as a tissue engineering scaffold. Tissue Eng Regen Med 13(4):343–351

Khang D, Kim SY, Liu-Snyder P, Palmore GTR, Durbin SM, Webster T (2007) Enhanced fibronectin adsorption on carbon nanotube/poly (carbonate) urethane: independent role of surface nano-roughness and associated surface energy. Biomaterials 28(32):4756–4768

Kai D, Prabhakaran MP, Jin G, Ramakrishna S (2011) Polypyrrole-contained electrospun conductive nanofibrous membranes for cardiac tissue engineering. J Biomed Mater Res Part A 99(3):376–385

Soleimani M, Mashayekhan S, Baniasadi H, Ramazani A, Ansarizadeh M (2018) Design and fabrication of conductive nanofibrous scaffolds for neural tissue engineering: process modeling via response surface methodology. J Biomater Appl 33(5):619–629

Mihardja SS, Sievers RE, Lee R (2008) The effect of polypyrrole on arteriogenesis in an acute rat infarct model. Biomaterials 29(31):4205–4210

Bendrea A-D, Cianga L, Cianga I (2011) Progress in the field of conducting polymers for tissue engineering applications. J Biomater Appl 26(1):3–84

Heath DE (2017) Promoting endothelialization of polymeric cardiovascular biomaterials. Macromol Chem Phys 218(8):1600574

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declaration of Conflicting interests

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tondnevis, F., Keshvari, H. & Mohandesi, J.A. Physico-mechanical and in vitro characterization of electrically conductive electrospun nanofibers of poly urethane/single walled carbon nano tube by great endothelial cells adhesion for vascular tissue engineering. J Polym Res 26, 256 (2019). https://doi.org/10.1007/s10965-019-1916-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1916-0