Abstract

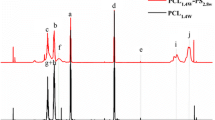

A series of epoxy modified with acrylic amphiphilic block copolymer (BCP) were prepared with different BCP contents. The compatibility between BCP and epoxy matrix was characterized by differential scanning calorimetry (DSC). The nanostructures in the thermosets were investigated by means of atomic force microscopy (AFM). The thermal stability and degradation kinetics of BCP/epoxy blends were investigated that by thermogravimetric analysis (TGA) in N2 atmosphere. The ‘model free method (Vyazovkin’ method) and ‘model fitting’ methods (Coats-Redfern method, Málek method and ABS differential method) were applied to analyze the decomposition of cured neat epoxy and BCP/epoxy blends. The glass transition temperature (Tg) of the BCP/epoxy blends was found almost not affected by the incorporation of BCP. The miscibility of acrylic BCP in the epoxy matrix was verified by comparing the theoretical calculation with experimental results. AFM further confirmed the good miscibility of the blends. The thermal stability of the BCP/epoxy blends remained unchanged and the main decompose reaction was slightly accelerated from the perspective of transition state theory. The relationship between pre-exponential factor and reaction activation energy was established by utilizing the kinetic compensation parameter method. The degradation kinetics of both neat epoxy and BCP/epoxy blend were found abide to the Fn (n > 3/2) reaction mechanism.

Similar content being viewed by others

Data availability

The experimental data used to support the results of this study is include in the diagram of this paper. Except where it has been specially marked and acknowledge,the paper does not contain any research result that have been published or written by others. Welcome guidance and supervision.

References

Li T, Heinzer M, Francis L, Bates F (2016) Engineering superior toughness in commercially viable block copolymer modified epoxy resin. J Polym Sci Part B Polym Phys 54:189–204

Auvergne R, Caillol S, David G, Boutevin B, Pascault J (2014) Biobased thermosetting epoxy: present and future. Chem Rev 114:1082–1115

Zhao K, Song X, Liang C, Wang J, Xu S (2015) Morphology and properties of nanostructured epoxy blends toughened with epoxidized carboxyl-terminated liquid rubber. Iran Polym J 24:425–435

Heng Z, Li R, Chen Y, Zou H, Liang M (2016) Preparation of damping structural integration materials via the formation of nanostructure in triblock copolymer modified epoxy resins[J]. J Polym Res 23(7):128

Yuan Z, Yu J, He Z, Wu X, Rao B, Lu S, Jiang N (2014) Improved thermal properties of epoxy composites filled with thermotropic liquid crystalline epoxy grafted aluminum nitride[J]. Fibers Polym 15(12):2581–2590

Pfeifer CS (2014) Nanostructured multiphase polymer networks. Handbook of nanomaterials properties (pp. 1443–1464). Springer, Berlin

Heng Z, Chen Y, Zou H, Liang M (2015) Simultaneously enhanced tensile strength and fracture toughness of epoxy resins by a poly (ethylene oxide)-block-carboxyl terminated butadiene-acrylonitrile rubber dilock copolymer. RSC Adv 5:42362–42368

Kishi H, Kunimitsu Y, Nakashima Y (2015) Control of nanostructures generated in epoxy matrices blended with PMMA-b-PnBA-b-PMMA triblock copolymers. Express Polym Lett 9:23–35

Kishi H, Kunimitsu Y, Imade J, Oshitas S, Morishita Y, Asada M (2011) Nano-phase structures and mechanical properties of epoxy/acryl triblock copolymer alloys. Polymer 52:760–768

George S, Puglia D, Kenny J, Jyotishkumarp P, Thomas S (2012) Cure kinetics and thermal stability of micro and nanostructured thermosetting blends of epoxy resin and epoxidized styrene-block-butadiene-block-styrene triblock copolymer systems. Polym Eng Sci 52:2336–2347

Liu J, Thompson Z, Sue H, Bates F (2010) Toughening of epoxies with block copolymer micelles of wormlike morphology[J]. Macromolecules 43:7238–7243

Thio YS, Wu J, Bates FS (2009) The role of inclusion size in toughening of epoxy resins by spherical micelles. J Polym Sci Part B Polym Phys 47:1125–1129

Kubel J, Grubbs R, Saad W, Cook R (2003) Mechanical properties of block copolymer vesicle and micelle modified epoxies. J Polym Sci B Polym Phys 41:2444–2456

Zhang H, Heng Z , Chen Y, Zou H, Liang M, Zeng z (2018) The effect of reaction-induced micro-phase separation of block copolymer on curing kinetics of epoxy thermosets[J]. J Polym Res 25(4):98

Francis R, Baby DK (2016) A reactive polystyrene-block-polyisoprene star copolymer as a toughening agent in an epoxy thermoset[J]. Colloid Polym Sci 294(3):565–574

Xu Z, Zheng S (2007) Reaction-induced microphase separation in epoxy thermosets containing poly(ε-caprolactone)-block-poly(n-butyl acrylate) Diblock copolymer[J]. Macromolecules 40(7):2548–2558

Uchiumi, N., Hamada, K., Kato, M., Ono, T., Yaginuma, S., & Ishiura, K. (2001). U.S. Patent No. 6,329,480. Washington, DC: U.S. Patent and Trademark Office

Hamada, K., Ishiura, K., Kato, M., & Yaginuma, S. (2003). U.S. Patent No. 6,555,637. Washington, DC: U.S. Patent and Trademark Office

Oertel, J., Kishii, S., Kilian, D., Hamada, K., Morishita, Y., Kurihara, T., & Ito, T. (2010). Acrylic TPE approaching automotive. TPE Magazine International 1, 34–35

Vyazovkin S, Chrissafis K, Di Lorenzo ML, Koga N, Pijolat M, Roduit B, Sbirrazzuoli N, Sunol J (2014) ICTAC kinetics committee recommendations for collecting experimental thermal analysis data for kinetic computations. Thermochim Acta 590:1–23

Chiu Y, Chou I, Tseng W, Ma C (2008) Preparation and thermal properties of diglycidylether sulfone epoxy. Polym Degrad Stab 93:668–676

Aouf C, Nouailhas H, Fache M, Caillol S, Boutevin B, Fulcrand H (2013) Multi-functionalization of gallic acid. Synthesis of a novel bio-based epoxy resin[J]. Eur Polym J 49:1185–1195

Doyle CD (1961) Estimating thermal stability of experimental polymers by empirical thermogravimetric analysis. Anal Chem 33:77–79

Wu C, Liu Y, Chiu Y, Chiu YS (2002) Thermal stability of epoxy resins containing flame retardant components: an evaluation with thermogravimetric analysis. Polym Degrad Stab 78:41–48

Olszak-Humienik M (2001) Dependence of thermal decomposition rate constant on temperature of reaction. J Thermanal Calorim 65:515–518

Carrasco F, Dionisi D, Martinelli A, Majone M (2006) Thermal stability of polyhydroxyalkanoates. J Appl Polym Sci 100:2111–2121

Marinović-Cincović M, Janković B, Jovanović V, Samarzijia-Jovanovic S, Markovic G (2013) The kinetic and thermodynamic analyses of non-isothermal degradation process of acrylonitrile-butadiene and ethylene-propylene-diene rubbers. Compos B Eng 45:321–332

Turmanova S, Genieva S, Vlaev L (2011) Kinetics of nonisothermal degradation of some polymer composites: change of entropy at the formation of the activated complex from the reagents. J Thermodyn 2011:1–10

Vyazovkin S, Burnham A, Criado J, Perez-Maqueda L, Popescu C, Sbirrazzuoli N (2011) ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19

Vyazovkin S (1997) Advanced isoconversional method. J Therm Anal 49:1493–1499

Doyle C (1962) Estimating isothermal life from thermogravimetric data. J Appl Polym Sci 6:639–642

Málek J (1992) The kinetic analysis of non-isothermal data. Thermochim Acta 200:257–269

Senum G, Yang R (1977) Rational approximations of the integral of the Arrhenius function. J Therm Anal 11:445–447

Cano L, Builes D, Tercjak A (2014) Morphological and mechanical study of nanostructured epoxy systems modified with amphiphilic poly (ethylene oxide-b-propylene oxide-b-ethylene oxide) triblock copolymer. Polymer 55:738–745

Kwei T (1984) The effect of hydrogen bonding on the glass transition temperatures of polymer mixtures. J Polym Sci Polym Lett Ed 22:307–313

Wu J, Thio Y, Bates F (2005) Structure and properties of PBO–PEO diblock copolymer modified epoxy. J Polym Sci Part B Polym Phys 43:1950–1965

Guo Q, Thomann R, Gronski W (2002) Phase behavior, crystallization, and hierarchical nanostructures in self-organized thermoset blends of epoxy resin and amphiphilic poly (ethylene oxide)-b lock-poly (propylene oxide)-b lock-poly (ethylene oxide) triblock copolymers. Macromolecules 35:3133–3144

Meng Y, Zhang X (2014) Nanostructured epoxy composites[J]. Micro-and nanostructured epoxy/rubber blends 53-72

Kishi H, Kunimitsu Y, Nakashima Y, Abe T, Imade S, Oshita S, Morishita Y, Asada M (2015) Control of nanostructures generated in epoxy matrices blended with PMMA-b-PnBA-b-PMMA triblock copolymers[J]. Express Polym Lett 9(1):23–35

Liu J, Thompson Z, Sue H, Bates F (2010) Toughening of epoxies with block copolymer micelles of wormlike morphology[J]. Macromolecules 43(17):7238–7243

George S, Hameed N, Jose S, George J, Parameswaranpillai J (2016) Dynamical mechanical thermal analysis of epoxy-/block-copolymer blends[J]

Lizymol P, Thomas S (1993) Thermal behaviour of polymer blends: a comparison of the thermal properties of miscible and immiscible systems. Polym Degrad Stab 41:59–64

Guinesi LS, da Róz AL, Corradini E, Mattoso L, Teixeria E, Curvelo A (2006) Kinetics of thermal degradation applied to starches from different botanical origins by non-isothermal procedures[J]. Thermochim Acta 447:190–196

Arshad MA, Maaroufi A, Benavente R, Perena J (2013) Thermal degradation kinetics of insulating/conducting epoxy/Zn composites under nonisothermal conditions[J]. Polym Compos 34:2049–2060

Levchik SV, Weil ED (2004) Thermal decomposition, combustion and flame-retardancy of epoxy resins-a review of the recent literature. Polym Int 53:1901–1929

Levchik S, Camino G, Luda M, Costa L, Costes B, Henry Y, Muller G, Morel E (1995) Mechanistic study of thermal behaviour and combustion performance of epoxy resins. II. TGDDM/DDS system[J]. Polym. Degrad. Stabil 48:359–370

Dyakonov T, Mann PJ, Chen Y, Stevenson WTK (1996) Thermal analysis of some aromatic amine cured model epoxy resin systems-II: residues of degradation. Polym Degrad Stab 54:67–83

Lin SC, Bulkin BJ, Pearce EM (1979) Epoxy resins. III Application of fourier transform IR to degradation studies of epoxy systems. J Polym Sci 17:3121–3148

Zhao Y, Yan N, Feng MW (2013) Thermal degradation characteristics of phenol–formaldehyde resins derived from beetle infested pine barks. Thermochim Acta 555:46–52

Wang Z, Han E, Ke W (2006) Effect of acrylic polymer and nanocomposite with nano-SiO2 on thermal degradation and fire resistance of APP–DPER–MEL coating[J]. Polym Degrad Stab 91:1937–1947

Montserrat S, Málek J, Colomer P (1998) Thermal degradation kinetics of epoxy–anhydride resins: I.: influence of a silica filler[J]. Thermochim Acta 313:83–95

Acknowledgements

We gratefully acknowledge support from the Ministry of Education Key Laboratory for the Synthesis and Application of Organic Functional Molecules.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, P., Zou, L., Zha, S. et al. Compatibility and thermal decomposition behavior of acrylic block copolymer modified epoxy resin. J Polym Res 27, 4 (2020). https://doi.org/10.1007/s10965-019-1903-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1903-5