Abstract

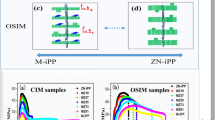

In this article, two kinds of isotactic polypropylene (iPP)/high density molecular weight polyethylene (HDPE) blend samples were prepared by an accessible injection-molding method. These two samples contain iPP shish kebab matrix and HDPE dispersed phase (shish kebab and epitaxy crystal, respectively). The variation of microstructures upon annealing was characterized using scanning electron microscopy, differential scanning calorimetry and small-angle X-ray scattering. It was found that the variations of different crystalline structures were changed by varying annealing parameters. Only the rearrangement of partially melted chains into primary lamellae happened for the sample with epitaxy crystalline structure, which was distinguished from the sample with HDPE shish kebab structure. Moreover, the variation of the crystalline structure, crystallinity and melting point were discussed to account for the changes in mechanical properties. These results revealed the relationship among the morphology, annealing parameters and mechanical properties, which provide a practical method to industrial manufacture.

Similar content being viewed by others

References

Blom HP, Teh JW, Bremner T, Rudin A (1998) Isothermal and non-isothermal crystallization of PP: effect of annealing and of the addition of HDPE. Polymer 39(17):4011–4022

Ferrer-Balas D, Maspoch ML, Martinez AB, Santana OO (2001) Influence of annealing on the microstructural, tensile and fracture properties of polypropylene films. Polymer 42(4):1697–1705

Frontini PM, Fave A (1995) The effect of annealing temperature on the fracture performance of isotactic polypropylene. J Mater Sci 30(9):2446–2454

Pralay Maiti; Masamichi Hikosaka, ‡; Koji Yamada; Akihiko Toda, A.; Gu†, F., Lamellar Thickening in Isotactic Polypropylene with High Tacticity Crystallized at High Temperature. Macromolecules 2000, 33 (33), 9069–9075

Rastogi S, Spoelstra AB (1999) Chain mobility in polymer systems : on the borderline between solid and melt 1. Lamellar doubling during annealing of polyethylene. Macromolecules 30(25):7880–7889

Bai H, Deng H, Zhang Q, Wang K, Fu Q, Zhang Z, Men Y (2012) Effect of annealing on the microstructure and mechanical properties of polypropylene with oriented shish-kebab structure. Polym Int 61(2):252–258

Bai H, Wang Y, Zhang Z, Liang H, Li Y, Li L, Zhou Z, Men Y (2009) Influence of annealing on microstructure and mechanical properties of isotactic polypropylene with β-phase nucleating agent. Macromolecules 42(17):6647–6655

Han L, Li X, Li Y, Huang T, Wang Y, Wu J, Xiang F (2010) Influence of annealing on microstructure and physical properties of isotactic polypropylene/calcium carbonate composites with β-phase nucleating agent. Mater Sci Eng A 527(13):3176–3185

Wang L, Zhang QP, Wang JH, Yang B, Yang MB, Feng JM (2014) Effects of annealing on the hierarchical crystalline structures and mechanical properties of injection-molded bars of high-density polyethylene. Polym Int 63(2):296–306

Liu D, Jian K, Ming X, Cao Y (2013) Effect of annealing on phase structure and mechanical behaviors of polypropylene hard elastic films. J Polym Res 20(5):126

Xu R, Sheng Z, Wang J, Jian K, Ming X, Feng Y (2018) Impact of different die draw ratio on crystalline and oriented properties of polypropylene cast films and annealed films. J Polym Res 25(6):142

Hedesiu C, §; Demco DE., ‡; Kleppinger R; Vanden Poel G; Gijsbers W; Blümich B; Remerie K, a.; VM (2007) Litvinov, effect of temperature and annealing on the phase composition, molecular mobility, and the thickness of domains in isotactic polypropylene studied by proton solid-state NMR, SAXS, and DSC. Macromolecules 40 (40), 3977–3989

Yao YF, Graf R, Spiess HW, Rastogi S (2008) Restricted segmental mobility can facilitate medium-range chain diffusion: a NMR study of morphological influence on chain dynamics of polyethylene. Macromolecules 41(7):2514–2519

Somani RH, Yang L, Zhu L, Hsiao BS (2005) Flow-induced shish-kebab precursor structures in entangled polymer melts. Polymer 46(20):8587–8623

Zhang, A.; Xiao, C.; Wu, Y.; Li, C.; Ji, Y.; Li, L.; Hu, W.; Wang, Z.; Ma, W.; Li, W. (2016) Effect of Fluorination on Molecular Orientation of Conjugated Polymers in High Performance Field-Effect Transistors. Macromolecules 49 (17)

Jiang J, Liu X, Lian M, Pan Y, Chen Q, Liu H, Zheng G, Guo Z, Schubert DW, Shen C (2018) Self-reinforcing and toughening isotactic polypropylene via melt sequential injection molding. Polym Test 67:183–189

Mi D-S, Hou F-Y, Zhou M, Zhang J (2018) Distribution of α-, β-, and γ-phases in a multi-flow injection-molded hierarchical structure. Chin J Polym Sci 6:1–11

Wang X, Pan Y, Qin Y, Voigt M, Liu X, Zheng G, Chen Q, Schubert DW, Liu C, Shen C (2018) Creep and recovery behavior of injection-molded isotactic polypropylene with controllable skin-core structure. Polym Test 69:478–484

Li Z, Bing N, Tian N, Lv R, Zou S (2011) Enhanced molecular orientation and strain hardening in melt-spun isotactic polypropylene monofilaments through partial melting recrystallization. J Appl Polym Sci 123(2):995–999

Gross B, Peterman J (1984) Synergisms of mechanical properties in blends of semi-crystalline polymers. J Mater Sci 19(1):105–112

Lotz B; Wittmann JC (2010) Polyethylene–isotactic polypropylene epitaxy: Analysis of the diffraction patterns of oriented biphasic blends. J Polym Sci B Polym Phys 25 (5), −

Petermann J, Xu Y (1991) The origin of heteroepitaxy in the system of uniaxially oriented isotactic polypropylene and polyethylene. J Mater Sci 26(5):1211–1215

Petermann J, Broza G, Rieck U, Kawaguchi A (1987) Epitaxial interfaces in semi-crystalline polymers and their applications. J Mater Sci 22(4):1477–1481

Zhou M, Mi D, Hou F, Zhang J (2017) Tailored crystalline structure and mechanical properties of isotactic polypropylene/high molecular weight polyethylene blend. Ind Eng Chem Res 56(29):8385–8392

Na B, Zhang Q, Wang K, Li L, Fu Q (2005) Origin of various lamellar orientations in high-density polyethylene/isotactic polypropylene blends achieved via dynamic packing injection molding: bulk crystallization vs. epitaxy. Polymer 46(3):819–825

Su R, Wang K, Zhang Q, Chen F, Fu Q, Hu N, Chen E (2011) Epitaxial crystallization and oriented structure of linear low-density polyethylene/isotactic polypropylene blends obtained via dynamic packing injection molding. Polym Adv Technol 22(2):225–231

Su R, Wang K, Zhang Q, Chen F, Fu Q, Xu W, Na B (2009) Orientation and epitaxy in the injection-molded bars of linear low-density polyethylene/isotactic polypropylene blends: an infrared dichroism measurement. J Phys Chem B 113(21):7423–7429

Zhi-hao; Zhao; Fei-fei; Wang; Zhou; Kai-zhi; Shen; Zhang (2016) Altering the Hierarchical Morphology Distribution of Injection Molded Polyethylene by the Introduction of Crosslink Network and Periodical Shear. Chin J Polym Sci 34 (12), 1479–1489

Ren-xi; Qi-xiong; Zhou; Chao; Da-shan; Zhang (2015) The Banded Spherulites of iPP Induced by Pressure Vibration Injection Molding. Chin J Polym Sci 33 (11), 1625–1632

Deng P, Whiteside B, Wang F, Norris K, Zhang J (2014) Epitaxial growth and morphological characteristics of isotactic polypropylene/polyethylene blends: scale effect and mold temperature. Polym Test 34:192–201

Olley RH, Bassett DC (1982) An improved permanganic etchant for polyolefines. Polymer 23(12):1707–1710

Shouke Yan DY (1998) Jürgen Petermann, controlling factors for the occurrence of heteroepitaxy of polyethylene on highly oriented isotactic polypropylene. Polymer 39(19):4569–4578

Gu X, Wang Y, Jiang Y, Liu M, Fu Q, Zhang J (2019) High impact performance induced by a synergistic effect of heteroepitaxy and oriented layer-unoriented layer alternated structure in iPP/HDPE injection molded part. Polymer 175:206–214

Niu B, Chen JB, Chen J, Xu J, Zhong GJ, Li ZM (2015) Crystallization of linear low density polyethylene on in situ oriented isotactic polypropylene substrate manipulated by extensional flow field. Crystengcomm 18(1):77–91

Donnay M, Ponçot M, Tinnes JP, Schenk T, Ferry O, Royaud I (2017) In situ study of the tensile deformation micro-mechanisms of semi-crystalline POLY(ETHYLENE terephthalate) films using synchrotron radiation X-ray scattering. Polymer 117:268–281

Housmans JW, Gahleitner M, Peters GWM, Han EHM (2009) Structure–property relations in molded, nucleated isotactic polypropylene. Polymer 50(10):2304–2319

Liu X, Dai K, Hao X, Zheng G, Liu C, Schubert DW, Shen C (2013) Crystalline structure of injection molded β-isotactic polypropylene: analysis of the oriented shear zone. Ind Eng Chem Res 52(34):11996–12002

Acknowledgements

This work was financially supported by The National Natural Science Foundation of China (No. 0030905401227). The authors also express sincere thanks to the Shanghai Synchrotron Radiation Facility (SSRF), China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gu, X., Zhou, M., Wang, Y. et al. Influence of annealing on the morphology and mechanical properties of iPP/HDPE blend with tailored oriented crystalline structures. J Polym Res 26, 194 (2019). https://doi.org/10.1007/s10965-019-1864-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1864-8