Abstract

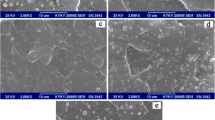

The effects of water and carbonyl sulfide (COS) in propylene feed of polymerization process were examined in relation to the physical and mechanical properties of synthesized polypropylene (PP). The Samples were analyzed using gel permeation chromatography, scanning electron microscopy (SEM), differential scanning calorimetry (DSC), X-ray diffractometry (WAXS) and mechanical test. Molecular mass and isotacticity of PP were reduced by increasing poisons due to the limitation of the movement of polymer chains. The SEM images indicated that the effect of water and COS poisons on polymer morphology was insignificant. The results of DSC and optical tests revealed that an increase in water and COS poisons significantly increased the transparency of PP, which had been originated from the reduction of surface irregularities caused by escalated polymer atacticity. Nevertheless, the improvement in optical properties was very little for other properties, such as gloss and yellow index. The XRD results confirmed lower crystallinity due to escalated atacticity because of increased poisons. Furthermore, comparison of poison-contained and poison-free samples indicated that an increase in the amount of poisons led to greater tensile strength and heat distortion temperature (HDT). Since it is crucial to achieve the ultimate properties of the polymer, mechanical properties of the polymer should be considered to achieve improved transparency.

Similar content being viewed by others

References

Cong Y, Hong Z, Zhou W, Chen W, Su F, Li H, Li X, Yang K, Yu X, Qi Z, Li L (2012) Conformational ordering on the growth front of isotactic polypropylene. Spherulite. Macromol 45:8674–8680

De Rosa C, Auriemma F, Di Girolamo R (2013) Morphology and mechanical properties of the mesomorphic form of isotactic polypropylene in stereodefective polypropylene. Macromolecules 46:5202–5214

De Rosa C, Auriemma F, Di Girolamo R (2008) The double role of comonomers on the crystallization behavior of isotactic polypropylene: propylene-hexene copolymers. Macromolecules 41:2172–2177

Taghaddosi S, Akbari A, Yegani R (2017) Preparation, characterization and anti-fouling properties of nanoclays embedded polypropylene mixed matrix membranes. Chem Eng Res Des 125:35–45

Nakamura K, Shimizu S, Umemoto S, Thierry A, Lotz B, Okui N (2008) Temperature dependence of crystal growth rate for [alpha] and [beta] forms of isotactic polypropylene. Polym J 40:915–922

Zia Q, Androsch R, Radusch H-J, Piccarolo S (2006) Morphology, reorganization and stability of mesomorphic nanocrystals in isotactic polypropylene. Polymer 47:8163–8172

Gadzinowska K, Piorkowska E (2003) Influence of sample thickness and surface nucleation on i-PP crystallization kinetics in DSC measurements. Polimery 48:790–799

Funaki A, Takubo T, Kanai T (2016) Experimental analysis for extrusion screw geometry to produce highly transparent polypropylene sheets. Polym Eng Sci 50:420–427

Sun C, Chen H, Guo B, Song G, Li P, Li Y, Gao J (2016) Changes of optical properties in the aging process of polypropylene. J Food Saf Qual 7(3):1203–1209

Xinli X, Xueying Q, Deyan K, Wenbo Z (2016) Optically transparent high temperature shape memory polymers. Soft Matter 12:2894–2900

Paulino C (2016) Biaxially oriented high density polyethylene film with improved sealant layer. Mater Des 103:32-39. Paulino CM, inventor; Toray Plastics (America) Inc, assignee. Biaxially oriented high density polyethylene film with improved sealant layer. United States patent US 9,676,169. 2017

Feldmann M (2016) The effects of the injection moulding temperature on the mechanical properties and morphology of polypropylene man-made cellulose fibre composites. Appl Sci Manufact 87:146–152

Barbe PC, Cecchin G, Noristi L (1987) The catalytic system Ti-complex/MgCl 2. In catalytical and radical polymerization. Springer, Berlin, Heidelberg, pp 1–81

Terano M, Soga K (1994 Nov 1) Catalyst design for tailor-made polyolefins. Elsevier

Pino P, Cioni P, Wei J (1987) Asymmetric hydrooligomerization of propylene. J Am Chem Soc 109:6189–6191

Maddah HA (2016) Polypropylene as a promising plastic: A review. Am J Polym Sci 6:1):1–1):1

De Santis F, Pantani R (2013) Optical properties of polypropylene upon recycling. Sci World J. https://doi.org/10.1155/2013/354093

Shibayama M, Imamura K-I, Katoh K, Nomura S (1991) Transparency of recycled polypropylene film. J Appl Polym Sci 42:1451–1458

Sukhadia A-M, Rohlfing D-C, Johnson M-B, Wilkes G-L (2002) A comprehensive investigation of the origins of surface roughness and Haze in polyethylene blown films. J Appl Polym Sci 85:2396–2411

Miwa T, Masayuki Y (2007) Structure and properties of injection-molded polypropylene with sorbitol-based clarifier. Polym Eng Sci 47:1441

Ahmad Z, Kumar K-D, Saroop M, Preschilla N, Biswas A, Bellare J-R, Bhowmik A (2010) Highly transparent thermoplastic elastomer from isotactic polypropylene and styrene/ethylene-butylene/styrene triblock copolymer: structure-property correlations. Polym Eng Sci 50:331–341

Stockland R-A, Foley S-R, Jordan R-F (2003) Reaction of Vinyl Chloride with Group 4 Metal Olefin Polymerization Catalysts. J Am Chem Soc 125:796–809

Bernland K, Goossens J, Smith P, Tervoort T (2016) On clarification of haze in polypropylene. J Polym Sci 54:865–874

Li X, Guo C, Zhang Y, Liu K, Zhang J (2015) The morphology and mechanical properties of isotactic polypropylene injection-molded samples with the presence of β-nucleation agent and periodical shear field. J Macromol Sci Part B 54:215–229

Janiak C, Blank F (2006) Metallocene catalysts for olefin oligomerization. InMacromolecular symposia 236(1) 14-22. Weinheim: WILEY-VCH Verlag.

Quijada R, Rojas R, Bazan G, Komon ZJA, Mauler RS, Galland GB (2001) Synthesis of branched polyethylene from ethylene by tandem action of iron and zirconium single site catalysts. Macromolecules 34:2411–2417

Lin CY, Chen MC, Mehta AK (2001) Assessment of Metallocene Propylene Polymers for Cast Film Applications. J Plast Film Sheet 17:113–127

DeMeuse TM (2002) Processing and Film Properties of Polypropylene Made Using Metallocene Catalysts. J Plast Film Sheet 18:17–23

Crosby CR, Chatterjee AM (2001) Effect of Formulation Parameters on Optical and Frictional Properties of Tubular Water Quenched Polypropylene Films. J Plast Film Sheet 17:128–151

Xu T, Yu J, Jin Z (2001) Effects of crystalline morphology on the impact behavior of polypropylene. Mater Des 22:27–31

Gocek I, Adanur S (2009) Effect of processing parameters on polypropylene film properties. InThe Fiber Society 2009 Fall Meeting and Technical Conference, The University of Georgia, Athens, GA

Fatahi S, Ajji A, Lafleur P-G (2005) Correlation between structural parameters and property of PE blown films. J Plast Film Sheeting 21:281–305

Khanarian G (2000) Rubber toughened and optically transparent blends of cyclic olefin copolymers. Polym Eng Sci 40:2590–2601

Trezza TA, Krochta JM (2001) Specular reflection, gloss, roughness and surface heterogeneity of biopolymer coatings. J Appl Polym Sci 79:2221–2229

Darncholvichit M (2003) Haze band formation and morphological composition in blown film extrusion. University of Massachusetts Lowell, Lowell

Wang L, Kamal M-R (2001) Light transmission and haze of polyethylene blown thin films. Polym Eng Sci 41:358–372

Rinker JW (1979) Surface properties of blown low density polyethylene films. Paper synthetics conference, Proceedings of the Technical Association of the Pulp and Paper Industry, Washington, DC, USA, pp 129–136

Stehing FC, Speed CS, Westerman L (1981) Causes of haze of low-density polyethylene blown films. Macromolecules 14:698–708

Harban A-A, Samuel R (1967) Polymerization of olefins in the presence of a coordination catalyst and carbonyl sulfide, US Patent 3317502 A

Garoff T, Liskola E, Sormunen P(1987) Transition metals and organometallics as catalysts for olefin polymerization, ed. by Kaminsky, W and Sinn H, Springer-Verlag, Berlin, p.197.

Tangjituabun K, Kim SY, Hiraoka Y, Taniike T, Terano M, Jongsomjit B, Praserthdam P (2008) Effects of various poisoning compounds on the activity and stereospecificity of heterogeneous Ziegler–Natta catalyst. Sci Technol Adv Mater 9(2):024402

Alshaiban A (2011) Propylene polymerization using 4th generation Z-N Catalysts: Polymerization kinetics and polymer microstructure investigation, Ph.D. Thesis Waterloo University

Dashti A, Ramazani A (2009) Kinetic and morphological investigation on the Mg(OEt)2 based Z-N catalyst for propylene polymerization using typical external donor. Macromol Symp 285:52–57

SakuraT NY, Kasahara T, Mizunuma K, Yamaguchi N, Tashiro K, Amemiya Y (2005) Structural deformation behavior of isotactic polypropylene with different molecular characteristics during hot drawing process. Polymer 46(20):8846–8858

Lotz B, Wittmann J, Lovinger A (1996) Structure and morphology of poly (propylenes): a molecular analysis. Polymer 37(22):4979–4992. https://doi.org/10.1016/0032-3861(96)00370-9.

Morrow DR, Newman BA (1968) Crystallization of low-molecular-weight polypropylene fractions. J Appl Phy 39(11):4944–4950. https://doi.org/10.1063/1.1655891

Van der Burgt F (2002) Crystallization of isotactic polypropylene: the influence of stereo-defects (Masters thesis). Technical University of Eindhoven, Eindhoven.

De Rosa C, Auriemma F, Di Capua A, Resconi L, Guidotti S, Camuratie I (2004) Structure−property correlations in polypropylene from metallocene catalysts: stereodefective, regioregular isotactic polypropylene. J Am Chem Soc 126(51):17040–17049

Dealy J-M, Larson R-G (2006) Structure and Rheology of Molten Polymers. Hanser, Munich

Sandler SR, Karo W, Bonesteel J, Pearce EM (1998) Polymer Synthesis and Characterization. Academic, USA

Brandrup J, Immergut E-H, Grulke E-A (1999) Polymer Handbook. John Wiley and Sons, New York

Mark J-E (1999) Polymer Data Handbook. Oxford University, NewYork

Farrow G (1963) Crystallite size’and melting point of polypropylene. Polymer 4:191–197

Horváth Z, Menyhárd A, Doshev P, Gahleitner M, Vörös G, Varga J, Pukánszky B (2014) Effect of the molecular structure of the polymer and nucleation on the optical properties of polypropylene homo-and copolymers. ACS Appl Mater Inter 6:7456–7463

Phulkerd P, Hirayama S, Nobukawa S, Inoue T, Yamaguchi M (2014) Sstructure and mechanical anisotropy of injection-molded polypropylene with a plywood structure. Polym J 46:226–233

Lai WC (2011) T he effect of self-assembled nanofibrils on the morphology and microstructure of poly (l-lactic acid). Soft Matter 7:3844–3851

Yamaguchi M, Fukui T, Okamoto K, Sasaki S, Uchiyama Y, Ueoka C (2009) Anomalous molecular orientation of isotactic polypropylene sheet containing N, N′-dicyclohexyl-2, 6-naphthalenedicarboxamide. Polymer 50:1497–1504

Uchiyama Y, Iwasaki S, Ueoka C, Fukui T, Okamoto K, Yamaguchi M (2009) Molecular orientation and mechanical anisotropy of polypropylene sheet containing N, N′-dicyclohexyl-2, 6-naphthalenedicarboxamide. J Polym Sci Part B Polym Phys 47:424–433

Tenma M, Mieda N, Takamatsu S, Yamaguchi M (2008) Structure and properties for transparent polypropylene containing sorbitol-based clarifier. J Polym Sci Part B Polym Phys 46:41–47

Wei Z, Zhang W, Chen G, Liang J, Yang S, Wang P, Liu L (2010) Crystallization and melting behavior of isotactic polypropylene nucleated with individual and compound nucleating agents. Journal of thermal analysis and calorimetry 102(2):775–783

Feng Y, Jin X, Hay J (1998) Effect of nucleating agent addition on crystallization of isotactic polypropylene. J Appl Polym Sci 69:2089–2095

Simanke A-G, de Azeredo A-P, de Lemos C, Mauler R-S (2016) Influence of nucleating agent on the crystallization kinetics and morphology of polypropylene. Polímeros 26:152–160

Pukhszky B, Mudra I, Staniek P (1997) Relation of crystalline structure and mechanical properties of nucleated polypropylene. J Vinyl Add Technol 3:53–57

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arjmand, S., Shakeri, A. & Arabi, H. Effect of water and carbonyl sulfide toxins in gas propylene feed in polymerization process on physical properties of polypropylene. J Polym Res 26, 195 (2019). https://doi.org/10.1007/s10965-019-1860-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1860-z