Abstract

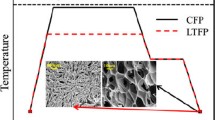

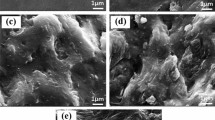

Based on the industrialized graphene oxide (GO) product, a series of polyurethane-imide (PUI)/GO nano-composite foams were fabricated via in situ prepolymer foaming method. It was found that the formation of hydrogen bonding and covalent bonding between two phases of the composite led to a highly efficient grafting of PUI molecules on the GO surface with high layer thickness, and thus partial exfoliation and uniform dispersion of GO in the matrix were achieved. By addition of proper content of GO (0.5~1 wt%), the relatively uniform cell morphology with thick walls can be observed, and the smaller mean cell size and narrower cell size distributions were presented compared with PUI foam, due to the nucleation effect of GO on PUI foam. TGA analysis presented two steps of degradation process for PUI/GO foams, and the thermal degradation temperatures increased remarkably with GO content at the second degradation stage. Meanwhile the degradation activation energy and the frequency factor increased, indicating the remarkable improvement of the thermal oxidative stability of PUI by compositing with GO. With increasing GO content, the storage modulus and Tg increased first, reaching maximum at 1 wt% GO, and then decreased. At ambient temperature, the storage modulus of PUI/1 wt% GO foam reached as high as 623 MPa, increasing by 48% compared with PUI foam, indicating an obvious reinforcing effect of GO on PUI foam. By addition of GO, the oxygen permeability coefficient decreased significantly, and the radical scavenging ratio increased, which was favorable for inhibiting the oxidative degradation of PUI molecules.

Similar content being viewed by others

References

Qian H, Xiong W, Baijie Z, Fanzhuo M, Jilin P (2014) Preparation and properties of highly branched poly(urethane-imide)-epoxy cross-linked copolymer. Des Monomers Polym 17:445–452

Aswini KM, Chattopadhyay DK, Sreedhar B, Raju KVSN (2006) FTIR and XPS studies of polyurethane-urea-imide coatings. Prog Org Coat 55:231–243

Qin Y, Lin Y (2013) Mechanical and thermal properties of polyurethane elastomers synthesized with toluene Diisocyanate trimer. J Macromol Sci B 52:138–154

Zhengmian C, Gregory BF, Amanda GH, Bruce O, Robert B, Moore GLW, Richard T (2015) Synthesis and Properties of Segmented Polyurethanes with Triptycene Units in the Soft Segment. Macromol Chem Phys 216:1180–1191

Bing H, Lin Y (2017) Highly heat-resistant silicon-containing polyurethane-imide copolymers: synthesis and thermal mechanical stability. Eur Polym J 91:337–353

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA (2004) Electric field effect in atomically thin carbon films. Science 306:666–669

Sham AY, Notley SM (2013) A review of fundamental properties and applications of polymer-graphene hybrid materials. Soft Matter 9:6645–6653

Lee SK, Rana K, Ahn JH (2013) Graphene films for flexible organic and energy storage devices. J Phys Chem Lett 4:831–841

Chen J, Li C, Shi G (2013) Graphene materials for electrochemical capacitors. J Phys Chem Lett 4:1244–1253

Hoseinabadi M, Naderi M, Najafi M, Motahari S, Shokri M (2017) A study of rigid polyurethane foams: the effect of synthesized polyols and nanoporous grapheme. J Appl Polym Sci 134. https://doi.org/10.1002/APP.45001

Yan D, Xu L, Chen C, Tang J, Ji X, Li Z (2012) Enhancedmechanical and thermal properties of rigid polyurethane foam composites containing graphene nanosheets and carbon nanotubes. Polym Int 61:1107–1114

Wan YJ, Tang LC, Gong LX (2014) Grafting of epoxy chains onto graphene oxide for epoxy composites with improved mechanical and thermal properties. Carbon 69:67–80

Ji Y, Ma J, Liang B (2005) In situ polymerization and in situ compatibilization of polymer blends of poly (2, 6-dimethyl-1, 4-phenylene oxide) and polyamide 6. Mater Lett 59:1997–2000

Szabó T, Berkesi O, Forgó P, Josepovits K, Sanakis Y, Petridis D, Dékány I (2006) Evolution of surface functional groups in a series of progressively oxidized graphite oxides. Chem Mater 18:2740–2749

Ly TH, Duong DL, Ta QH, Yao F, Vu QA, Jeong HY, Chae SH, Lee YH (2013) Nondestructive characterization of graphene defects. Adv Funct Mater 23:5183–5189

Guo J, Ren L, Wang R, Zhang C, Yang Y, Liu T (2011) Water dispersible graphene noncovalently functionalized with tryptophan and its poly (vinyl alcohol) nanocomposite. Compos Part B 42:2130–2135

Gu J, Yang X, Lv Z, Li N, Liang C, Zhang Q (2016) Functionalized graphite nanoplatelets/epoxy resin nanocomposites with high thermal conductivity. Int J Heat Mass Transf 92:15–22

Gu JW, Li N, Tian LD, Lv ZY, Zhang QY (2015) High thermal conductivity graphite nanoplatelet/UHMWPE nanocomposites. RSC Adv 5:36334–36339

Wang J, Tsuzuki T, Tang B, Hou X, Sun L, Wang H (2012) Reduced graphene oxide/ZnO composite: reusable adsorbent for pollutant management. ACS Appl Mater Interfaces 4:3084–3090

Shu R, Yin Q, Xing H, Tan D, Gan Y, Xu G (2016) Colloidal and rheological behavior of aqueous graphene oxide dispersions in the presence of poly (ethylene glycol). Colloids Surf A Physicochem Eng Asp 488:154–161

Gong R, Xu Q, Chu Y, Gu X, Ma J, Li R (2015) A simple preparation method and characterization of epoxy reinforced microporous phenolic open-cell sound absorbent foam. RSC Adv 5:68003–68013

Sbirrazzuoli N, Brunel D, Elegant L (1992) Different kinetic equations analysis. J Therm Anal 38:1509–1524

Coats AW, Redfern JP (1964) Kinetic parameters from thermogravimetric data. Nature 201:68–69

Zhang B, Liu H, Han J (2018) Aluminum phosphate microcapsule flame retardants for flexible polyurethane foams. J Phys Chem Solids 115:199–207

Luo F, Wu K, Lu M, Yang L, Shi J (2017) Surface modification of aluminum hypophosphite and its application for polyurethane foam composites. J Therm Anal Calorim 129:767–775

Wang Z, Li X (2018) Mechanical properties and flame Retardancy of rigid polyurethane foams containing SiO2 Nanospheres/graphene oxide hybrid and dimethyl Methylphosphonate. Polym-Plast Technol Eng 57:884–892

Xu Q, Hong T, Zhou Z, Gao J, Xue L (2018) The effect of the trimerization catalyst on the thermal stability and the fire performance of the polyisocyanurate-polyurethane foam. Fire and Materials 42:119–127

Xu Z, Tang X, Aijuan G, Fang Z, Tong L (2017) Surface-modifiers of clay on mechanical properties of rigid polyurethane foams/Organoclay nanocomposites. J Appl Polym Sci 105:2988–2995

Ye L, Meng X-Y, Ji X, Li Z-M, Tang J-H (2009) Synthesis and characterization of expandable graphite–poly (methylmethacrylate) composite particles and their application to flame retardation of rigid polyurethane foams. Polym Degrad Stabil 94:971–979

Mensor LL, Menezes FS, Leitão GG, Reis AS, Santos TCD, Coube CS, Leitão SG (2001) Screening of Brazilian plant extracts for antioxidant activity by the use of DPPH free radical method. Phytother Res 15:127–130

Acknowledgements

This study was financially supported by Joint Fund of National Natural Science Foundation of China and China Academy of Engineering Physics (NSAF) (No. U1530144).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hui, B., Ye, L. & Zhao, X. In situ preparation of polyurethane-imide/graphene oxide nano-composite foam: intercalation structure and thermal mechanical stability. J Polym Res 25, 267 (2018). https://doi.org/10.1007/s10965-018-1660-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-018-1660-x