Abstract

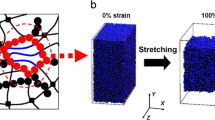

In current paper, we demonstrated that molecular dynamics and glass transition of rubber can be controlled by constructing attractive interface between rubber matrix and fillers. Based on a combination of experiments and molecular simulations, it was revealed that interfacial segmental mobility was reduced and glass transition temperatures (Tgs) of epoxidized natural rubber (ENR) were significantly improved due to in situ polymerization of zinc dimethacrylate (ZDMA). During curing, ZDMA polymerizes in rubber matrix, resulting in the appearance of nanodispersion phases of poly-ZDMA (PZDMA). It was demonstrated that coordination interaction exists between epoxy groups and PZDMA in interfacial regions. Furthermore, using dynamic Monte Carlo simulations, it was observed that the interfacial regions that have highest content of epoxy groups exhibit lowest segmental mobility. Then, the increase of ZDMA content leads to the rise of the fraction of absorbed interfacial segments, and thus the Tgs of filled rubbers are improved.

Similar content being viewed by others

References

Rauline R (1992) Rubber compound and tires based on such a compound. Eur Patent 0501227:A1

Rauline R (1993) Copolymer rubber composition with Silica filler, tire having base of said composition and method of preparing same, US Patent US005227425A

Hilonga A, Kim JK, Sarawade PB, Quang DV, Shao GN, Elineema G, Kim HT (2012) Synthesis of mesoporous silica with superior properties suitable for green tire. J Ind Eng Chem 18:1841–1844

Liu J, Zheng Z, Li F, Lei W, Gao Y, Wu Y, Zhang L, Wang Z (2016) Nanoparticle chemically end-linking elastomer network with super-low hysteresis loss for fuel-saving automobile. Nano Energy 28:87–96

Sperling LH, Fay JJ (1991) Factors which affect the glass transition and damping capability of polymers. Polym Adv Technol 2:49–56

Qu L, Yu G, Wang L, Li C, Zhao Q, Li J (2012) Effect of filler-elastomer interactions on the mechanical and nonlinear viscoelastic behaviors of chemically modified silica-reinforced solution-polymerized styrene butadiene rubber. J Appl Polym Sci 126:116–126

Zhou X, Wang R, Lei W, Qiao H, Ji H, Zhang L, Hua K, Kulig J (2015) Design and synthesis by redox polymerization of a bio-based carboxylic elastomer for green tire. Sci Chin Chem 58:1561–1569

Suhr J, Koratkar N, Keblinski P, Ajayan P (2005) Viscoelasticity in carbon nanotube composites. Nat Mater 4:134–137

Gao Y, Liu J, Zhang L, Cao D (2014) Existence of a glassy layer in the polymer-nanosheet interface: evidence from molecular dynamics. Macromol Theory Simul 23:36–48

Starr FW, Schroder TB, Glotzer SC (2002) Molecular dynamics simulation of a polymer melt with a nanoscopic particle. Macromolecules 35:4481–4492

Kaufman S, Slichter WP, Davis DD (1971) Nuclear magnetic resonance study of rubber-carbon black interactions. J Polym Sci Polym Phys 9:829–839

Metin B, Blum FD (2006) Segmental dynamics in poly(methyl acrylate) on silica: molecular-mass effects. J Chem Phys 125:054707

Tsagaropoulos G, Eisenberg A (1995) Dynamic mechanical study of the factors affecting the two glass transition behavior of filled polymers. Similarities and differences with random ionomers. Macromolecules 28:6067–6077

Litvinov VM, Orza RA, Klüppel M, Duin MV, Magusin PCMM (2011) Rubber-filler interactions and network structure in relation to stress-strain behavior of vulcanized, carbon black filled EPDM. Macromolecules 44:4887–4900

Vo LT, Anastasiadis SH, Giannelis EP (2011) Dielectric study of poly(styrene-co-butadiene) composites with carbon black, silica, and nanoclay. Macromolecules 44:6162–6171

Berriot J, Montes H, Lequeux F, Long D, Sotta P (2002) Evidence for the shift of the glass transition near the particles in silica-filled elastomers. Macromolecules 35:9756–9762

Hao T, Zhou Z, Wang Y, Liu Y, Zhang D, Nie Y, Wei Y, Li S (2017) Segmental dynamics in interfacial region of composite materials. Monatsh Chem 148:1285–1293

Ramanathan T, Abdala AA, Stankovich S et al (2008) Functionalized graphene sheets for polymer nanocomposites. Nat Nanotechnol 3:327–331

Oh H, Green PF (2009) Polymer chain dynamics and glass transition in athermal polymer/nanoparticle mixtures. Nat Mater 8:139–143

Lin T, Ma S, Lu Y, Guo B (2014) New design of shape memory polymers based on natural rubber crosslinked via Oxa-Michael reaction. ACS Appl Mater Interfaces 6:5695–5703

Lin T, Guo B (2013) Curing of rubber via Oxa-Michael reaction toward significantly increased aging resistance. Ind Eng Chem Res 52:18123–18130

Tocuchet P, Rodriguez G, Gatza PE, Butler DP, Crawford D, Teets AR, Fener HO, Flanagan DP (1989) Rubber compound for tracked vehicle track pads. US Patent 4:843,114

Medalia AI, Alesi AL, Mead JL (1992) Pattern abrasion and other mechanisms of wear of tank track pads. Rubber Chem Technol 65:154–175

Lu YL, Liu L, Yang C, Tian M, Zhang LQ (2005) The morphology of zinc dimethacrylate reinforced elastomers investigated by SEM and TEM. Eur Polym J 41:577–588

Lu YL, Liu L, Tian M, Geng HP, Zhang LQ (2005) Study on mechanical properties of elastomers reinforced by zinc dimethacrylate. Eur Polym J 41:589–598

Peng Z, Liang X, Zhang Y, Zhang Y (2002) Reinforcement of EPDM by in situ prepared zinc dimethacrylate. J Appl Polym Sci 84:1339–1345

Ikeda T, Yamada B, Tsuji M, Sakurai S (1999) In situ copolymerization behaviour of zinc dimethacrylate and 2-(N-ethylperfluoro-octanesulphonamido)ethyl acrylate in hydrogenated nitrile–butadiene rubber during peroxide crosslinking. Polym Int 48:446–454

Lu Y, Liu L, Shen D, Yang C, Zhang LQ (2004) Infrared study on in situ polymerization of zinc dimethacrylate in poly(α-octylene-co-ethylene) elastomer. Polym Int 53:802–808

Yuan X, Zhang Y, Peng Z, Zhang Y (2002) In situ preparation of magnesium methacrylate to reinforce NBR. J Appl Polym Sci 84:1403–1408

Nie Y, Huang G, Qu L, Zhang P, Weng G, Wu J (2010) Cure kinetics and morphology of natural rubber reinforced by the in situ polymerization of zinc dimethacrylate. J Appl Polym Sci 115:99–106

Nomura A, Takano J, Toyoda A, Saito T (1993) Structural analysis of high strength HNBR/ZDMA composites. J Jpn Rubber Soc 66:830–838

Dontsov A, De Candia F, Amelino L (1972) Elastic properties and structure of polybutadiene vulcanized with magnesium methacrylate. J Appl Polym Sci 16:505–518

Chen Y, Xu C, Cao L, Wang Y, Fang L (2013) Morphology study of peroxide-induced dynamically vulcanized polypropylene/ethylene-propylene-diene monomer/zinc dimethacrylate blends during tensile deformation. J Phys Chem B 117:7819–7825

Nie Y, Huang G, Liu Z, Qu L, Zhang P, Weng G, Wu J (2010) Improved mechanical properties and special reinforcement mechanism of natural rubber reinforced by in situ polymerization of zinc dimethacrylate. J Appl Polym Sci 116:920–928

Nie Y (2015) Strain-induced crystallization of natural rubber/zinc dimethacrylate composites studied using synchrotron X-ray diffraction and molecular simulation. J Polym Res 22:1–10

Hu WB, Mathot VBF, Frenkel D (2003) Phase transitions of bulk statistical copolymers studied by dynamic Monte Carlo simulations. Macromolecules 36:2165–2175

Nie Y, Gao H, Wu Y, Hu W (2014) Thermodynamics of strain-induced crystallization of random copolymers. Soft Matter 10:343–347

Arroyo M, López-Manchado MA, Herrero B (2003) Organo-montmorillonite as substitute of carbon black in natural rubber compounds. Polymer 44:2447–2453

Chen Y, Xu C (2011) Crosslink network evolution of nature rubber/zinc dimethacrylate composite during peroxide vulcanization. Polym Compos 32:1505–1514

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702–1706

Ozawa T (1965) A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn 38:1881–1886

Eisenberg A, Hird B, Moore RB (1990) A new multiplet-cluster model for the morphology of random ionomers. Macromolecules 23:4098–4107

Malmierca MA, González-Jiménez A, Mora-Barrantes I et al (2014) Characterization of network structure and chain dynamics of elastomeric ionomers by means of 1h low-field NMR. Macromolecules 47:5655–5667

Hall LM, Seitz ME, Winey KI, Opper KL, Wagener KB, Stevens MJ, Frischknecht AL (2012) Ionic aggregate structure in ionomer melts: effect of molecular architecture on aggregates and the ionomer peak. J Am Chem Soc 134:574–587

Xu C, Cao L, Huang X, Chen Y, Lin B, Fu L (2017) Self-healing natural rubber with tailorable mechanical properties based on ionic supramolecular hybrid network. ACS Appl Mater Interfaces 9:29363–29373

Chueangchayaphan W, Tanrattanakul V, Chueangchayaphan N, Muangsap S, Borapak W (2017) Synthesis and thermal properties of natural rubber grafted with poly (2-hydroxyethyl acrylate). J Polym Res 24:107–114

Thongnuanchan B, Ninjan R, Kaesaman A, Nakason C (2015) Studies on the ambient temperature crosslinking of latex films based on natural rubber grafted with poly (diacetone acrylamide) using DMTA. J Polym Res 22:115–125

Zhang X, Tang Z, Guo B, Zhang L (2016) Enabling design of advanced elastomer with bioinspired metal-oxygen coordination. ACS Appl Mater Interfaces 8:32520–32527

Luo Z, Cheng W, Chen H, Fu X, Peng X, Luo F, Nie L (2013) Preparation and properties of enzyme-modified cassava starch–zinc complexes. J Agric Food Chem 61:4631–4638

Nie Y, Ye X, Zhou Z, Yang W, Tao L (2014) Intrinsic correlations between dynamic heterogeneity and conformational transition in polymers during glass transition. J Chem Phys 141:074901

Nie Y, Ye X, Zhou Z, Hao T, Yang W, Lu H (2015) Structural characteristics of a cooperatively rearranging region during the glass transition of a polymer system. RSC Adv 5:17726–17731

Lu H, Zhou Z, Hao T, Ye X, Nie Y (2015) Temperature dependence of structural properties and chain configurational study: a molecular dynamics simulation of polyethylene chains. Macromol Theory Simul 24:335–343

Ye X, Zhou Z, Nie Y, Ma P, Hao T, Yang W, Lu H (2016) Comparative study on dynamical heterogeneity of ring and linear polymers. Macromol Theory Simul 25:9–15

Nie Y, Ye X, Qiu X et al (2018) Molecular simulations of fragility of linear and ring polymers. Comput Mater Sci 142:200–205

Nie Y, Zhou Z, Hao T, Ye X, Yang W (2016) The distribution of glass transition temperatures in ultrathin polymer films controlled by segment density or interfacial interaction. Macromol Theory Simul 25:187–195

Xie Z, Fu X, Wei L et al (2017) New evidence disclosed for the engineered strong interfacial interaction of graphene/rubber nanocomposites. Polymer 118:30–39

Acknowledgements

The financial supports from the National Natural Science Foundation of China (No. 21404050) are gratefully acknowledged. The Research Foundation of Jiangsu University (No. 14JDG059), the Jiangsu Planned Projects for Postdoctoral Research Funds (No. 1402019A), and the Postdoctoral Science Foundation of China (No. 2015 M580394) are also appreciated.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

ESM 1

(DOCX 64 kb)

Rights and permissions

About this article

Cite this article

Wei, Y., Wu, H., Weng, G. et al. Effect of interface on bulk polymer: control of glass transition temperature of rubber. J Polym Res 25, 173 (2018). https://doi.org/10.1007/s10965-018-1566-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-018-1566-7