Abstract

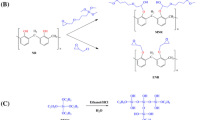

4-hydroxymethyl phenylboronic acid (4-HMPBA), phenol and formaldehyde were for the first time to synthesize boron containing novolac phenolic resins (Novolac-4-HMPBA). Its corresponding carbon fibers (CF) composites were also fabricated via the lamination followed by hot-compression. Results revealed that Novolac-4-HMPBA was successfully synthesized. Compared to common novolac phenolic resin (NPR), the corresponding decomposition temperature of 5% weight loss (T 5 ) and char yield at 800 °C (C 800 ) of cured Novolac-4-HMPBA-30 were increased to 369.1 °C and 69.7%, increased by 41.3% and 26.3%, respectively. The CF/Novolac-4-HMPBA-20 composites presented relatively higher interlaminar shear strength (ILSS) of 35.9 MPa, increased by 50.2% compared to that of CF/NPR composites. After the treatment at 800 °C for one hour under Ar atmosphere, the corresponding ILSS value of CF/Novolac-4-HMPBA-20 composite was decreased to 7.8 MPa, but still higher than that of CF/NPR composites (3.0 MPa).

Similar content being viewed by others

References

Triantou KI, Mergia K, Perez B, Florez S, Stefan A, Ban C, Pelin G, Ionescuc G, Zuber C, Fischer WPP, Barcena J (2017) Thermal shock performance of carbon-bonded carbon fiber composite and ceramic matrix composite joints for thermal protection re-entry applications. Compos Part B 111:270

Gogoi JP, Bhattacharyya NS, Bhattacharyya S (2014) Single layer microwave absorber based on expanded graphite-novolac phenolic resin composite for X-band applications. Compos Part B 58:518

Wang Y, Chen LX, Xu TT, Yan Y, Gu JW, Yun J, Feng JJ (2017) High char yield novolac modified by Si-B-N-C precursor: Thermal stability and structural evolution. Polym Degrad Stab 137:184

Li QL, Chen L, Li XH, Zhang JJ, Zhang X, Zheng K, Fang F, Zhou HF, Tian XY (2016) Effect of multi-walled carbon nanotubes on mechanical, thermal and electrical properties of phenolic foam via in-situ polymerization. Compos Part A 82:214

Yun J, Chen LX, Zhang XF, Zhao H, Wen ZY, Zhang C (2017) The effect of silicon and ferrocene on the char formation of modified novolac resin with high char yield. Polym Degrad Stab 139:97

Bresson G, Ahmadi-Sénichault A, Caty O, Ayvazyan V, GregoriML CSF, Vignoles GL (2016) Thermographic and tomographic methods for tridimensional characterization of thermal transfer in silica/phenolic composites. Compos Part B 104:71

Yang MM, Yuan JY, Guo F, Wang K, Zhang ZZ, Men XH, Liu WM (2016) A biomimetic approach to improving tribological properties of hybrid PTFE/Nomex fabric/phenolic composites. Eur Polym J 78:163

Park JM, Kwon DG, Wang ZJ, Roh JU, Lee W, Park JK, De Vries KL (2014) Effects of carbon nanotubes and carbon fiber reinforcements on thermal conductivity and ablation properties of carbon/phenolic composites. Compos Part B 67:22

Vignoles GL, Aspa Y, Quintard M (2010) Modelling of carbon-carbon composite ablation in rocket nozzles. Compos Sci Technol 70:1303

Sykam N, Gautam RK, Kar KK (2015) Electrical, mechanical, and thermal properties of exfoliated graphite/phenolic resin composite bipolar plate for polymer electrolyte membrane fuel cell. Polym Eng Sci 55:917

Kim YA, Kamio S, Tajiri T, Hayashi T, Song SM, Endo M (2007) Enhanced thermal conductivity of carbon fiber/phenolic resin composites by the introduction of carbon nanotubes. Appl Phys Lett 90:093125

Li S, Chen FH, Zhang BX, Luo ZH, LiH ZT (2016) Structure and improved thermal stability of phenolic resin containing silicon and boron elements. Polym Degrad Stab 133:321

Green J (1996) Mechanisms for flame retardancy and smoke suppression-A review. J Fire Sci 14:426

Balc S, Sezgi NA, Eren E (2012) Boron oxide production kinetics using boric acid as raw material. Ind Eng Chem Res 51:312

Yun J, Chen LX, Zhang XF, Feng JJ, Liu LL (2016) The effect of introducing B and N on pyrolysis process of high ortho novolac resin. Polymers 8:35

Monni J, Niemelä P, Alvila L, Pakkanen TT (2008) Online monitoring of synthesis and curing of phenol-formaldehyde resol resins by Raman spectroscopy. Polymer 49:3865

Zhang Y, Shen S, Liu Y (2013) The effect of titanium incorporation on the thermal stability of phenol-formaldehyde resin and its carbonization microstructure. Polym Degrad Stab 98:514

Gao JG, Xia LY, Liu YF (1995) Structure of a boron-containing bisphenol-F formaldehyde resin and kinetics of its thermal degradation. Polym Degrad Stab 83:71

Wang SJ, Wang Y, Bian C, Zhong YH, Jing XL (2015) The thermal stability and pyrolysis mechanism of boron-containing phenolic resins: The effect of phenyl borates on the char formation. Appl Surf Sci 331:519

Wang SJ, Jing XL, Wang Y, Si JJ (2014) High char yield of aryl boron-containing phenolic resins: The effect of phenylboronic acid on the thermal stability and carbonization of phenolic resins. Polym Degrad Stab 99:1

Lin CT, Lee HT, Chen JK (2015) Preparation and properties of bisphenol-F based boron-phenolic resin/modified silicon nitride composites and their usage as binders for grinding wheels. Appl Surf Sci 330:1

Martín C, Ronda JC, Cádiz V (2006) Boron-containing novolac resins as flame retardant materials. Polym Degrad Stab 91:747

PJ X, Jing XL (2010) Pyrolysis of hyperbranched polyborate modified phenolic resin. Polym Eng Sci 50:1382

Abdalla MO, Ludwick A, Mitchell T (2003) Boron-modified phenolic resins for high performance applications. Polymer 44:7353

Malkowsky IM, Fröhlich R, Griesbach U, Pütterand H, Waldvogel SR (2006) Facile and reliable synthesis of tetraphenoxyborates and their properties. Eur J Inorg Chem 2006:1690

Pineschi M, Bertolini F, Haak PM, Crotti P, Macchia F (2005) Mild metal-free syn-stereoselective ring opening of activated epoxides and aziridines with aryl borates. Chem Commun 36:1426

Feng JJ, Chen LX, Gu JW, He ZY, Yun J, Wang XB (2016) Synthesis and characterization of aryl boron-containing thermoplastic phenolic resin with high thermal decomposition temperature and char yield. J Polym Res 23:97

Artmann A, Bianchi O, Soares MR (2010) Nunes, R.C.R.Rheokinetic investigations on the thermal cure of phenol-formaldehyde novolac resins. Mater Sci Eng, C 30: 1245

Wang Y, Wang SJ, Bian C, Zhong YH, Jing XL (2015) Effect of chemical structure and cross-link density on the heat resistance of phenolic resin. Polym Degrad Stab 111:239

Zhang XQ, Looney MG, Solomon DH (1997) The chemistry of novolac resins: 3.13 C and 15 N n.m.r. studies of curing with hexamethylenetetramine. Polymer 38:5835

Gouin X, Grange P, Bois L, L’Haridon P, Laurent Y (1995) Characterization process of the nitridation process of boric acid. J Alloys Compd 224:22

HQ W, Wei Q, He H, Yang BF, Zhang Q, Yang GY (2014) A new acentric metalborate Mg[B6O9(OH)2]·4H2O: synthesis, structure and optical property. Inorg. Chem Commun 46:69

Joseph WE, Weiss DLB (2010) A solid-State 11B NMR and computational study of boron electric field gradientand chemical shift tensors in boronic acids and boronic esters. J Phys Chem A 114:5119

Kashiwakura S, Takahashi T, Maekawa H, Nagasaka T (2010) Application of 11B MAS-NMR to the characterization of boron in coal fly ash generated from Nantun coal. Fuel 89:1006

Shapiro PJ, Jiang FL, Jin XP, Twamley B, Patton JT, Rheingold AL (2004) Zwitterionic phosphorus ylide adducts of boron-bridged ansa-zirconocene complexes as precatalysts for olefin polymerization. Eur J Inorg Chem 2004:3370. https://doi.org/10.1002/ejic.200300932

He GH, Yan N (2004) 13C NMR study on structure, composition and curing behavior of phenol-urea-formaldehyde resole resins. Polymer 45:6813

Masahiro N, Tada-aki Y, Yoshiaki N (2006) Determination of branch density for high-ortho novolac and random novolac using 13C-NMR. J Netw Polym 27:210

Wang SJ, Jing XL, Wang Y, Si JJ (2014) Synthesis and characterization of novel phenolic resins containing aryl-boron backbone and their utilization in polymeric composites with improved thermal and mechanical properties. Polym Adv Technol 25:152

Wang JG, Guo QG, Liu L, Song JR (2002) Study on the microstructural evolution of high temperature adhesives for graphite bonding. Carbon 40:2447

Ardelean I, Păşcuţă P (2004) Comparative vibrational study of xFe2O3·(1-x)[3B2O3·MO] (MO⇒CaO or CaF2) glass systems. Met Powder Rep 58:3499

Gu JW, Liang CB, Zhao XM, Gan B, Qiu H, Guo YQ, Yang XT, Zhang QY, Wang DY (2017) Highly thermally conductive flame-retardant epoxy nanocomposites with reduced ignitability and excellent electrical conductivities. Compos Sci Technol 139:83

Gu JW, Yang XT, Lv ZY, Li N, Liang CB, Zhang QY (2016) Functionalized graphite nanoplatelets/epoxy resin nanocomposites with high thermal conductivity. Int J Heat Mass Transf 92:15

Costa L, Montelera RL, Camino G, Well ED, Pearce EM (1997) Structure-charring relationship in phenol-formaldehyde type resins. Polym Degrad Stab 56:23

Liu CL, Guo QG, Shi JL, Liu L (2004) Microstructure evolution in preparation of carbon fibers from phenolic resin. New Carbon Mater 19:124

Ozaki J, Ohizumi W, Oya A (2000) A TG-MS study of poly (vinyl butyral) /phenol-formaldehyde resin blend fiber. Carbon 38:1515

Wang MC, Wei LH, Zhao T (2005) A novel condensation–addition-type phenolic resin (MPN): Synthesis, characterization and evaluation as matrix of composites. Polymer 46:9202

Acknowledgements

The authors are grateful for the support and funding provided by the Foundation of National Natural Science Foundation of China (Nos. 51773169 and 51403175); Space Supporting Fund from China Aerospace Science and Industry Corporation (No. 2017-HT-XG) and the Fundamental Research Funds for the Central Universities (No. 3102017jg02003).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Feng, J., Li, J., Chen, L. et al. Enhanced thermal stabilities and char yields of carbon fibers reinforced boron containing novolac phenolic resins composites. J Polym Res 24, 176 (2017). https://doi.org/10.1007/s10965-017-1338-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-017-1338-9