Abstract

Thermoplastic polyurethane (TPU)/olefin block copolymer (OBC)/polycaprolactone (PCL) blends (70/20/10 and 50/30/20) were melt-blended to form the first environmental OBC-based triple-shape memory polymer blends. In this work, PCL with low crystalline temperature (switching phase), OBC with medium crystalline temperature (switching phase), and TPU with high crystalline temperature (fixed phase) could form an alternative triple-shape memory polymer (TSMP). Two compatibilizers, OBC-g-glycidyl methacrylate (OBC-g-GMA) and dicumyl peroxide, were confirmed to show a synergistic effect in enhancing the compatibility further through the morphological observation. Crystallinity of both OBC and PCL in the blends with or without modification decreased in comparison with that of pure resin. For dual-shape behaviors, the shape fixing ratio (Rf) and shape recovery ratio (Rr) were up to 96.3% and 91.2% for the GMA and peroxide-modified blends (50/30/20). The higher amount of TPU didn’t give higher recovery ratio, but instead slightly lower Rr due to the morphology difference. For triple-shape behaviors, both TPU/OBC/PCL blend compositions with or without GMA or peroxide modifications gave high Rf(C→B) values in the first fixing stage, but slightly lower values Rf(B→A) in the second fixing stage, especially for (70/20/10) case. On the other hand, a reverse trend was observed for two recovery stages. To enhance the Rf(B→A) in the second fixing stage, higher deformation temperatures were considered, and a measurable increment on Rf(B→A) was attained. Through this subtle adjustment on the temperature difference between high and low deformation temperatures, the theoretical multi-shape memory shape could be readily tailored to meet different applications.

Similar content being viewed by others

References

Ratna D, Karger-Kocsis J (2008) Recent advances in shape memory polymers and composites: a review. J Mater Sci 43(1):254–269

Leng J, Lan X, Liu Y, Du S (2011) Shape-memory polymers and their composites: stimulus methods and applications. Prog Mater Sci 56(7):1077–1135

Meng H, Li G (2013) A review of stimuli-responsive shape memory polymer composites. Polymer 54(9):2199–2221

Lewis CL, Dell EM (2016) A review of shape memory polymers bearing reversible binding groups, J. Polym. Sci., part B: Polym. Phys 54(14):1340–1364

Wang H, Taha A, Chum SP, Hiltner A, Baer E (2007) Comparison of block and random ethylene-octene copolymers based on the structure and elastomeric properties. Annu Tech Conf Conf Proc 2:1181–1185

Zhang Q, Feng J (2013) Difunctional olefin block copolymer/paraffin form-stable phase change materials with simultaneous shape memory property. Sol Energy Mater Sol Cells 117:259–266

Zhang Q, Cui K, Feng J, Fan J, Li L, Wu L, Huang Q (2015) Investigation on the recovery performance of olefin block copolymer/hexadecane form stable phase change materials with shape memory properties. Sol Energy Mater Sol Cells 132:632–639

Zhang Q, Hua W, Feng J (2016) A facile strategy to fabricate multishape memory polymers with controllable mechanical properties. Macromol Rapid Commun 37(15):1262–1267

Pretsch T (2010) Durability of a polymer with triple-shape properties. Polym Degrad Stab 95(12):2515–2524

Luo X, Mather PT (2010) Triple-shape polymeric composites (TSPCs). Adv Funct Mater 20(16):2649–2656

Zotzmann J, Behl M, Feng Y, Lendlein A (2010) Copolymer networks based on poly(ω-pentadecalactone) and poly(ϵ-caprolactone)segments as a versatile triple-shape polymer system. Adv Funct Mater 20(20):3583–3594

Ware T, Hearon K, Lonnecker A, Wooley KL, Maitland DJ, Voit W (2012) Triple-shape memory polymers based on self-complementary hydrogen bonding. Macromolecules 45(2):1062–1069

Narendra Kumar U, Kratz K, Behl M, Lendlein A (2012) Shape-memory properties of magnetically active triple-shape nanocomposites based on a grafted polymer network with two crystallizable switching segments. Express Polym Lett 6(1):26–40

Ge Q, Luo X, Iversen CB, Mather PB, Dunn ML, Qi HJ (2013) Mechanisms of triple-shape polymeric composites due to dual thermal transitions. Soft Matter 9(7):2212–2223

Bai Y, Zhang X, Wang Q, Wang T (2014) A tough shape memory polymer with triple-shape memory and two-way shape memory properties. J Mater Chem A 2(13):4771–4778

Wu Y, Hu J, Zhang C, Han J, Wang Y, Kumar B (2015) A facile approach to fabricate a UV/heat dual-responsive triple shape memory polymer. J Mater Chem A 3(1):97–100

Cuevas JM, Rubio R, Germán L, Laza JM, Vilas JL, Rodriguez M, León LM (2012) Triple-shape memory effect of covalently crosslinked polyalkenamer based semicrystalline polymer blends. Soft Matter 8(18):4928–4935

Radusch HJ, Kolesov I, Gohs U, Heinrich G (2012) Multiple shape-memory behavior of polyethylene/polycyclooctene blends cross-linked by electron irradiation. Macromol Mater Eng 297(12):1225–1234

Zhao J, Chen M, Wang X, Zhao X, Wang Z, Dang ZM, Ma L, Hu GH, Chen F (2013) Triple shape memory effects of cross-linked polyethylene/polypropylene blends with cocontinuous architecture. ACS Appl Mater Interfaces 5(12):5550–5556

Hoeher R, Raidt T, Krumm C, Meuris M, Katzenberg F, Tiller JC (2013) Tunable multiple-shape memory polyethylene blends. Macromol Chem Phys 214(23):2725–2732

Wang Z, Zhao J, Chen M, Yang M, Tang L, Dang ZM, Chen F, Huang M, Dong X (2014) Dually actuated triple shape memory polymers of cross-linked polycyclooctene-carbon nanotube/polyethylene nanocomposites. ACS Appl Mater Interfaces 6(22):20051–20059

Samuel C, Barrau S, Lefebvre JM, Raquez JM, Dubois P (2014) Designing multiple-shape memory polymers with miscible polymer blends: evidence and origins of a triple-shape memory effect for miscible PLLA/PMMA blends. Macromolecules 47(19):6791–6803

Kolesov I, Dolynchuk O, Radusch HJ (2015) Shape-memory behavior of cross-linked semi-crystalline polymers and their blends. Express Polym Lett 9(3):255–276

Karger-Kocsis J, Kéki S (2014) Biodegradable polyester-based shape memory polymers: concepts of (supra)molecular architecturing. Express Polym Lett 8(6):397–412

Kashif M, Chang YW (2015) Triple-shape memory effects of modified semicrystalline ethylene–propylene–diene rubber/poly(ɛ-caprolactone) blends. Eur Polym J 70:306–316

Gu S-Y, Liu L-L, Gao X-F (2015) Triple-shape memory properties of polyurethane/polylactide–polytetramethylene ether blends. Polym Int 64(9):1155–1162

Pandini S, Baldi F, Paderni K, Messori M, Toselli M, Pilati F, Gianoncelli A, Brisotto M, Bontempi E, Riccò T (2013) One-way and two-way shape memory behaviour of semi-crystalline networks based on sol–gel cross-linked poly(ε-caprolactone). Polymer 54(16):4253–4265

Wang HP, Chum SP, Hiltner A, Baer E (2009) Deformation of elastomeric polyolefin spherulites. J Polym Sci Part B Polym Phys 47(13):1313–1330

Bellin I, Kelch S, Langer R, Lendlein A (2006) Polymeric triple-shape materials. PNAS 103:18043–18047

Heuchel M, Sauter T, Kratz K, Lendlein A (2013) Thermally induced shape-memory effects in polymers: quantification and related modeling approaches. J Polym Sci Part B Polym Phys 51(8):621–637

Lai S-M, Wang X-F (2017) Shape memory properties of olefin block copolymer (OBC)/polycaprolactone (PCL) blends. (Early view). J Appl Polym Sci 134:45475

Pai F-C, Lai S-M, Chu HH (2013) Characterization and properties of reactive poly(lactic acid)/polyamide 610 biomass blends. J Appl Polym Sci 130(4):2563–2571

Al-Itry R, Lamnawar K, Maazouz A (2012) Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym Degrad Stab 97(10):1898–1914

Mishra JK, Chang YW, Kim DK (2007) Green thermoplastic elastomer based on polycaprolactone/epoxidized natural rubber blend as a heat shrinkable material. Mater Lett 61(17):3551–3554

Semba T, Kitagawa K, Ishiaku US, Kotaki M, Hamada HJ (2007) Effect of compounding procedure on mechanical properties and dispersed phase morphology of poly(lactic acid)/polycaprolactone blends containing peroxide. J Appl Polym Sci 103(2):1066–1074

Ma P, Hristova-Bogaerds DG, Lemstra PJ, Zhang Y, Wang S (2012) Toughening of PHBV/PBS and PHB/PBS blends via in situ compatibilization using dicumyl peroxide as a free-radical grafting initiator. Macromol Mater Eng 297(5):402–410

Ji D, Liu Z, Lan X, Wu F, Xie B, Yang M (2014) Morphology, rheology, crystallization behavior, and mechanical properties of poly(lactic acid)/poly(butylene succinate)/dicumyl peroxide reactive blends. J Appl Polym Sci 131(3):39580–39587

Han C, Ran X, Su X, Zhang K, Liu N, Dong L (2007) Effect of peroxide crosslinking on thermal and mechanical properties of poly(ε-caprolactone). Polym Int 56(5):593–600

Zhang H, Wang H, Zhong W, Du Q (2009) A novel type of shape memory polymer blend and the shape memory mechanism. Polymer 50(6):1596–1601

Lai S-M, Lan Y-C (2013) Shape memory properties of melt-blended polylactic acid (PLA)/thermoplastic polyurethane (TPU) bio-based blends. J Polym Res 20:140–147

Li J, Xie T (2011) Significant impact of thermo-mechanical conditions on polymer triple-shape memory effect. Macromolecules 44(1):175–180

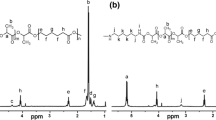

Lai SM, Wu WL, Wang YJ (2016) Annealing effect on the shape memory properties of polylactic acid (PLA)/thermoplastic polyurethane (TPU) bio-based blends. J Polym Res 23(5):1–13

Acknowledgments

The authors are grateful to Mr. Yen-Ju Chen and Geng-Lun Guo for helping manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lai, SM., You, PY., Chiu, Y.T. et al. Triple-shape memory properties of thermoplastic polyurethane/olefin block copolymer/polycaprolactone blends. J Polym Res 24, 161 (2017). https://doi.org/10.1007/s10965-017-1319-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-017-1319-z