Abstract

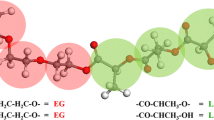

In this article, we present a coarse-grained (CG) model of poly(lactic acid) (PLA) developed by the iterative Boltzmann inversion (IBI) method. The coarse-grained potential was derived by matching the structural probability distribution functions to those of reference atomistic simulation. The resulting coarse-grained potential was found to be temperature-dependent when trying to reproduce the thermal expansion behavior of PLA. To satisfactory reproduce this behavior, the potential needs to be modified by a temperature factor of (T/T 0)0.3; T 0 = 327 K is the temperature at which the potential has been derived. The glass transition temperature (T g) as predicted by the modified CG potential compared favorably with those from experiment and atomistic simulation. Chain conformational properties were also evaluated in terms of a chain length (N)-radius of gyration (R g) relation and the persistence length. The model we develop was also noted to provide a considerable speed-up of computer time compared to its atomistic counterpart.

Similar content being viewed by others

References

Anderson KS, Schreck KM, Hillmyer MA (2008) Polym Rev 48:85–108

Lim LT, Auras R, Rubino M (2008) Prog Polym Sci 33:820–852

Baiardo M, Frisoni G, Scandola M, Rimelen M, Lips D, Ruffieux K, Wintermantel E (2003) J Appl Polym Sci 90:1731–1738

Auras R, Harte B, Selke S (2004) Macromol Biosci 4:835–864

Nampoothiri KM, Nair NR, John RP (2010) Bioresour Technol 101:8493–8501

Kale G, Kijchavengkul T, Auras R, Rubino M, Selke SE, Singh SP (2007) Macromol Biosci 7:255–277

Kulinski Z (2006) Piorkowska E, gadzinowska K, Stasiak M. Biomacromolecules 7:2128–2135

Li H, Huneault MA (2007) Polymer 48:6855–6866

Chen C-W, Huang C-I (2015) Polymer 77:189–198

Wang CI, Hsu CH, Hua CC, Chen SA (2013) J Polym Res 20:188

Jiang Z, Dou W, Sun T, Shen Y, Cao D (2015) J Polym Res 22:236

Zhang J, Liang Y, Yan JZ, Lou JZ (2007) Polymer 48:4900–4905

Jawalkar SS, Aminabhavi TM (2006) Polymer 47:8061–8071

Martinez d AI, Meaurio E, Coto B, Sarasua J-R (2010) Polymer 51:4431–4438

Zhou S-Q, Cheng X-C, Jin Y-L, Wu J, Zhao D-S (2013) J Appl Polym Sci 128:3043–3049

Binder K, Baschnagel J, Paul W (2003) Prog Polym Sci 28:115–172

Plante A, Palato S, Lebel O, Soldera A (2013) J Mater Chem C 1:1037–1042

Soldera A, Metatla N (2006) Phys Rev E 74:061803

Buchholz J, Paul W, Varnik F, Binder K (2002) J Chem Phys 117:7364–7372

Lee WJ, Ju SP, Wang YC, Chang JG (2007) J Chem Phys 127:064902

Wang Y-C, Ju S-P, Huang TJ, Wang H-H (2011) Nanoscale Res Lett 6:433

Reith D, Putz M, Muller-Plathe F (2003) J Comput Chem 24:1624–1636

Hsu DD, Xia WJ, Arturo SG, Keten S (2014) J Chem Theory Comput 10:2514–2527

Hess B, Kutzner C, van der Spoel D, Lindahl E (2008) J Chem Theory Comput 4:435–447

McAliley JH, Bruce DA (2011) J Chem Theory Comput 7:3756–3767

Jorgensen WL, Maxwell DS, Tirado-Rives J (1996) J Am Chem Soc 118:11225–11236

Brooks BR, Bruccoleri RE, Olafson BD, States DJ, Swaminathan S, Karplus M (1983) J Comput Chem 4:187–217

Hockney RW, Goel SP, Eastwood JW (1974) J Comput Phys 14:148–158

Nose S (1984) Mol Phys 100:191–198

Hoover WG (1985) Phys Rev A 31:1695–1697

Parrinello M, Rahman A (1981) J Appl Phys 52:7182–7190

Essmann U, Perera L, Berkowitz ML, Darden T, Lee H, Pedersen LG (1995) J Chem Phys 103:8577–8593

Hess B, Bekker H, Berendsen HJC, Fraaije JGEM (1997) J Comput Chem 18:1463–1472

Li M, Liu XY, Qin JQ, Gu Y (2009) Express Polym Lett 3:665–675

Yani Y, Lamm MH (2009) Polymer 50:1324–1332

Fischer J, Paschek D, Geiger A, Sadowski G (2008) J Phys Chem B 112:13561–13571

Prasitnok K, Wilson MR (2013) Phys Chem Chem Phys 15:17093–17104

Qian H-J, Carbone P, Chen X, Karimi-Varzaneh HA, Liew CC, Müller-Plathe F (2008) Macromolecules 41:9919–9929

Sasaki S, Asakura T (2003) Macromolecules 36:8385–8390

Hoogsteen W, Postema AR, Pennings AJ, Ten Brinke G, Zugenmaier P (1990) Macromolecules 1990, 23:634–642

De Santis P, Kovacs AJ (1968) Biopolymers 6:299–306

Dorgan J, Lehermeier H, Mang M (2000) J Polym Environ 8:1–9

Kanchanasopa M, Runt J (2004) Macromolecules 37:863–871

Yang S, Cui Z, Qu J (2014) J Phys Chem B 118:1660–1669

Gupta J, Nunes C, Jonnalagadda S (2013) Mol Pharm 10:4136–4145

Li D-X, Liu B-L, Y-s L, C-l C (2008) Cryobiology 56:114–119

Grosberg AY (2000) Phys Rev Lett 85:3858–3861

Chu JW, Voth GA (2006) Biophys J 90:1572–1582

Gautieri A, Russo A, Vesentini S, Redaelli A, Buehler MJ (2000) J Chem Theory Comput 6:1210–1218

Noy A, Golestanian R (2012) Phys Rev Lett 109:228101

Li X, Lehman W, Fischer S (2010) J Struct Biol 170:313–318

Sulatha MS, Natarajan U (2012) Ind Eng Chem Res 51:10833–10839

Aou K (2007) Effect of molecular structure on the thermal stability of amorphous and semicrystalline poly(lactic acid) Ph.D. Dissertation University of Massachusetts Amherst http://scholarworks.umass.edu/dissertations/AAI3293935

Xiang TX, Anderson BD (2014) J Pharm Sci 103:2759–2771

Acknowledgments

This research is financially supported by Faculthy of Science, Mahasarakham University, Thailand. The author would like to thank Prof. Visit Vao-soongnern, Laboratory of Computational and Applied Polymer Science, Suranaree University of Technology, Thailand, for the insightful discussions. The author would also like to thank one of the reviewers for bringing to our attention the important of evaluating the persistence length of the model.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prasitnok, K. A coarse-grained model for polylactide: glass transition temperature and conformational properties. J Polym Res 23, 139 (2016). https://doi.org/10.1007/s10965-016-1037-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-016-1037-y