Abstract

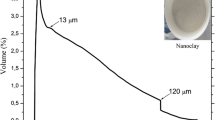

The structure, morphology and mechanical properties of polypropylene-nanoclay composites containing 1 to15 wt.% nanoclay was investigated. Combination of wide-angle x-ray diffraction (WAXD) and transmission electron microscopy (TEM) was used to determine nanocomposite morphology. Mixture of intercalated and exfoliated morphology was observed for all the samples. Samples with 1 to 5 wt.% clay showed shear induced orientation of clay platelets in the surface region of the molded bars. Glass transition temperature slightly decreased due to the plasticizing effect of additives. At higher weight percentage reinforcement (10–15 wt.%), up to 67 % improvement in tensile modulus is observed. Breaking energy was significantly improved for samples with up to 2 wt.% nanoclay additives. With further increase in nanoclay weight percentage, failure mode shifted from ductile to brittle. Increase in exclusion of clay additives at the boundary of spherulites and segregation of clay platelets were observed for samples with higher weight percentage of clay additives.

The structure, morphology and mechanical properties of polypropylene-nanoclay composites with 1 to 15 wt.% nanoclay additives were investigated. Mixture of intercalated and exfoliated morphology was observed in nanocomposites. At higher weight percentage reinforcement (10–15 wt.%), up to 67 % improvement in tensile modulus is observed. At higher weight percentage, exclusion of clay additives at the boundary of spherulites was observed. This study illustrates that along with the thermodynamic driving force, spherulite formation also drives the ultimate morphology

Similar content being viewed by others

References

Hegde RR, Bhat GS, Campbell RA (2008) Thermal bonding of polypropylene films and fibers. J Appl Polym Sci 110:3047–3058

Picard E, Vermogen A, Gérard JF, Espuche E (2007) Barrier properties of nylon 6-montmorillonite nanocomposite membranes prepared by melt blending: influence of the clay content and dispersion state: consequences on modeling. J Membr Sci 292:133–144. doi:10.1016/j.memsci.2007.01.030

Hegde RR, Bhat GS (2010) Nanoparticle effects on the morphology and mechanical properties of polypropylene spunbond webs. J Appl Polym Sci 118:3141–3155. doi:10.1002/app.32304

Hegde RR, Bhat GS (2009) Nanoparticle effects on structure and properties of polypropylene meltblown webs. J Appl Polym Sci 115:1062–1072. doi:10.1002/app.31089

Bhat GS, Hegde RR, Kamath MG, Deshpande B (2008) Nanoclay reinforced fibers and nonwovens. J Eng Fiber Fabr 3:3

Kojima Y, Usuki A, Kawasumi M, Okada A, Fukushima Y, Kurauchi T, Kamigaito T (1993) Mechanical properties of nylon 6-clay hybrid. J Mater Res 85:1185–1189. doi:10.1557/JMR.1993.1185

Vaiaa RA, Priceb G, Ruthc PN, Nguyend HT, Lichtenhand J (1999) Polymer/layered silicate nanocomposites as high performance ablative materials. Appl Clay Sci 15:67–92. doi:10.1016/S0169-1317(99)00013-7

Wanga K, Zhaoa P, Yanga H, Lianga S, Zhanga Q, Dua R, Fua Q, Yub Z, Chenb E (2006) Unique clay orientation in the injection-molded bar of isotactic polypropylene/clay nanocomposite. Polymer 47:7103–7110. doi:10.1016/j.polymer.2006.08.022

Hegde RR (2009) Structure and properties of nanoclay reinforced polymer films, fibers and nonwovens. PhD Dissertation. University of Tennessee. doi: http://trace.tennessee.edu/utk_graddiss/39

Hegde RR, Bhat GS, and Deshpande B (2012) Morphology and properties of nylon 6 blown films reinforced with different weight percentage of nanoclay additives. Int J Polym Sci 2012:1–14, Article ID 959035. doi: 10.1155/2012/959035

Chen L, Wong SC, Pisharath S (2003) Fracture properties of nanoclay-filled polypropylene. J Appl Polym Sci 88:3298–3305. doi:10.1002/app.12153

Hegde RR, Bhat GS, Deshpande B (2013) Crystallization kinetics and morphology of melt spun poly (ethylene terephthalate) nanocomposite fibers. Expr Polym Lett 7:821–831. doi:10.3144/expresspolymlett.2013.79

Hegde R, Henry N, Whittle B, Zang H, Hu B, Chen J, Xiao K, Dadmun M (2012) The impact of controlled solvent exposure on the morphology, structure and function of bulk heterojunction solar cells. Sol Energy Mater Sol Cells 107:112–124. doi:10.1016/j.solmat.2012.07.014

Dimitry OIH, Abdeen ZI, Ismail EA, Saad ALG (2010) Preparation and properties of elastomeric polyurethane/organically modified montmorillonite nanocomposites. J Polym Res 17:801–813

Fornes TD, Paul DR (2003) Crystallization behavior of nylon 6 nanocomposites. Polymer 44:3945–3961. doi:10.1016/S0032-3861(03)00344-6

Okamoto M, Hoai Nam P, Maiti P, Kotaka T, Hasegawa N, Usuki A (2001) House of cards structure in polypropylene/clay nanocomposites under elongational flow. Nano Lett 1:295–298. doi:10.1021/nl0100163

Yuan Q, Misra RDK (2006) Impact fracture behavior of clay-reinforced polypropylene nanocomposites. Polymer 47:4421–4433. doi:10.1016/j.polymer.2006.03.105

Xie S, Zhang S, Zhao B, Qin H, Wang F, Yang M (2005) Tensile fracture morphologies of nylon-6/montmorillonite nanocomposites. Polym Int 54:1673–1680. doi:10.1002/pi.1901

Hegde RR, Spruiell JE, Bhat GS (2013) Investigation of the morphology of Polypropylene-nanoclay nanocomposites. Polym Int. doi:10.1002/pi.4623

Hegde RR, Spruiell JE, Bhat GS (2012) Different crystallization mechanism in polypropylene-nanoclay nanocomposite with different weight percentage of nanoclay additives. J Mater Res 10:1360–1371. doi:10.1557/jmr.2012.37

Manzur A, Herna’ndez SF (2006) Activation energy for the glass transition of a confined elastomer in HDPE/PP blends. J Macromol Sci B Phys 45:139–152

ASTM Standards (2004) Standard test methods for determining the izod impact resistance of plastics, D. 256–04

Yuan Q, Deshmane C, Pesacreta TC, Misra RDK (2008) Nanoparticle effects on spherulitic structure and phase formation in polypropylene crystallized at moderately elevated pressures: the influence on fracture resistance. Mater Sci Eng A 480:181–188. doi:10.1016/j.msea.2007.07.019, Original Research Article

Ray SS, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processing. Prog Polym Sci 28:1539–1641. doi:10.1016/j.progpolymsci.2003.08.002

Shen L, Chauhari TW, Liu T (2005) Nanoindentation and morphological studies on injection-molded nylon-6 nanocomposites. Polymer 46:11969–11977. doi:10.1016/j.polymer.2005.10.006

Yalcin B, Cakmak M (2004) The role of plasticizer on the exfoliation and dispersion and fracture behavior of clay particles in PVC matrix: a comprehensive morphological study. Polymer 45:6623–6638. doi:10.1016/j.polymer.2004.06.061

Wang K, Chen F, Li Z, Fu Q (2013) Control of the hierarchical structure of polymer articles via “structuring” processing. Prog Polym Sci 17. doi: 10.1016/j.progpolymsci.2013.05.012

Bouhelal S, Cagiao ME, Benachour D, Djellouli B, Rong L, Hsiao BS, Baltá-Calleja FJ (2010) SAXS study applied to reversibly crosslinked isotactic polypropylene/clay nanocomposites. J Appl Polym Sci 117:3262–3270. doi:10.1002/app.32241

Valera-Zaragoza M, Ramı’rez-Vargas E, Medellı’n-Rodrı’guez FJ, Huerta-Martı’nez BM (2006) Thermal stability and flammability properties of heterophasic PPeEP/EVA/organoclay nanocomposites. Polym Degrad Stab 91:1319–1325

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mater Sci Eng 28:1. doi:10.1016/S0927-796X(00)00012-7

McCrum NG (1984) The kinetics of the α and β relaxations in isotactic polypropylene. Polymer 25:299–308. doi:10.1016/0032-3861(84)90281-7

Liu T, Ping Lim K, Chauhari Tjiu W, Pramoda KP, Chen ZK (2003) Preparation and characterization of nylon 11/organoclay nanocomposites. Polymer 44:3529. doi:10.1016/S0032-3861(03)00252-0

Alvert PD, Ryan TG (1978) Redistribution of impurities in crystallizing polymers. Polymer 19:611–616. doi:10.1016/0032-3861(78)90112-X

Friedrich K (1983) Advances in polymer science, Vol 52/53. Springer-Verlag Berlin, Heidelberg

Kausch HH (1978) Polymer fracture. Springer, Berlin-Heidelberg-New York

Nowacki R, Monasse B, Piorkowska E, Galeski A, Haudin JM (2004) Polymer 45:4877

Svoboda P, Zeng C, Wang H, Lee LJ, Tomasko DL (2002) Morphology and mechanical properties of polypropylene/organoclay nanocomposites. J Appl Polym Sci 85:1562–1570. doi:10.1002/app.10789

Ma J, Zhang S, Qi Z, Li G, Hu Y (2002) Crystallization behaviors of polypropylene/montmorillonite nanocomposites. J Appl Polym Sci 83:1978–1985. doi:10.1002/app.10127

Acknowledgments

Authors would like to acknowledge Techmer PM, Clinton, TN for providing the concentrates for this research. Financial support from the Center for Materials Processing (CMP) is also appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hegde, R.R., Bhat, G.S., Spruiell, J.E. et al. Structure and properties of polypropylene-nanoclay composites. J Polym Res 20, 323 (2013). https://doi.org/10.1007/s10965-013-0323-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-013-0323-1