Abstract

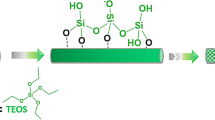

With ionic liquid namely 1-N-butyl-3-methylimidazolium chloride ([BMIM]Cl) as reaction medium in cellulose modification, maleic anhydride/glycidyl methacrylate-grafted ethylene-octene copolymer (POE-g-(MA/GMA)) was blended with cellulose by a co-rotating twin-screw extruder. Cellulose/POE-g-(MA/GMA) blend was examined by FTIR, 13C-NMR, WAXD, DSC, TGA, rheology and tensile properties. Owing to the reaction between functional groups of POE-g-(MA/GMA) and hydroxyl groups of cellulose and the high mobility of POE-g-(MA/GMA), hydrogen bond network in cellulose was destructed and cellulose-b-POE-g-(MA/GMA) copolymer was synthesized in-situ. As a result, the reduction in intermolecular force of cellulose improved the melt flowability and spinnability of cellulose blend. The formation of long-chain branches hindered the crystallization and increased the thermal stability of cellulose on one hand and obtained much more chemical bond fracture under stress action and increased the tensile strength and elongation at break of the blend fibers on the other. However, the addition of 15 wt% POE-g-(MA/GMA) led to the formation of crosslined structure, so a high degree of chain entanglement increased the dynamic viscosity and decreased the spinnability of cellulose/POE-g-(MA/GMA) blend.

Similar content being viewed by others

References

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymers and sustainable raw material. Angew Chem Int Ed 44(22):3358–3393

Klemm D, Philipp B, Heinze T, Heinze U (1998) Comprehensive cellulose chemistry: fundamentals and analytical methods. Wiley-VCH, Weinheim

Fink HP, Weigel P, Purz HJ, Ganster J (2001) Structure formation of regenerated cellulose materials from NMMO-solutions. Prog Polym Sci 26(9):1473–1524

Schlufter K, Schmauder HP, Dorn S, Heinze T (2006) Efficient homogeneous chemical modification of bacterial cellulose in the ionic liquid 1-N-butyl-3-methylimidazolium chloride. Macromol Rapid Commun 27(19):1670–1676

Kaur I, Bhalla TC, Sharma B (2011) Functionalization of cotton fabricorienting towards antibacterial activity. J Polym Res 18(3):347–358

Marhöfer RJ, Kast KM, Schilling B, Bär HJ, Kast SM, Brickmann J (2000) Molecular dynamics simulations of tertiary systems of cellohexaose/aliphatic N-oxide/water. Macromol Chem Phys 201(15):2003–2007

Zhang YP, Shao HL, Wu CX, Hu XC (2001) Formation and characterization of cellulose membranes from N-methylmorpholine-N-oxide solution. Macromol Biosci 1(4):141–148

Chen X, Burger C, Fang D, Ruan D, Zhang L, Hsiao BS, Chu B (2006) X-ray studies of regenerated cellulose fibers wet spun from cotton linter pulp in NaOH/thiourea aqueous solutions. Polymer 47(8):2839–2848

Zahran MK (2006) Grafting of methacrylic acid and other vinyl monomers onto cotton fabric using Ce (IV) Ion–cellulose thiocarbonate redox system. J Polym Res 13(1):65–71

Liu CF, Sun RC, Zhang AP, Ren JL, Geng ZC (2006) Structural and thermal characterization of sugarcane bagasse cellulose succinates prepared in ionic liquid. Polym Degrad Stabil 91(12):3040–3047

Zhang YH, Cui JB, Lynd LR, Kuang LR (2006) A transition from cellulose swelling to cellulose dissolution by o-phosphoric acid: evidence from enzymatic hydrolysis and supramolecular structure. Biomacromolecules 7(2):644–648

Ahn Y, Hu DH, Hong JH, Lee SH, Kim HJ, Kim H (2012) Effect of co-solvent on the spinnability and properties of electrospun cellulose nanofiber. Carbohyd Polym 89(2):340–345

Gilbert RD, Venditti RA, Zhang CS, Koelling KW (2000) Melt spinning of thermotropic cellulose derivatives. J Appl Polym Sci 77(2):418–423

Hermanutz F, Karstens T, Stein A (2005) New cellulosic materials produced by thermoplastic processing of silylcellulose. Lenzinger Berichte 84:86–91

Yamaguchi M, Iwasaki T, Okada K, Okamoto K (2009) Control of optical anisotropy of cellulose esters and their blends with plasticizer. Acta Mater 57(3):823–829

Yoshitaka A, Hiroyuki Y, Yuuhei M, Hiroshi T, Misa O, Yoshiyuki N, Mariko Y (2006) Thermoplastic cellulose derivative composition and fiber comprising the same. US Patent 6 984 631

Heinze T, Schwikal K, Barthel S (2005) Ionic liquids as reaction medium in cellulose functionalization. Macromol Biosci 5(6):520–525

Wu J, Zhang J, Zhang H, He J, Ren Q, Guo M (2004) Homogeneous acetylation of cellulose in a new ionic liquid. Biomacromolecules 5(2):266–268

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124(31):9074–9082

Nishiyama Y, Sugiyama J, Chanzy H, Langan P (2003) Crystal structure and hydrogen-bonding system in cellulose Iα from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 125(19):14300–14306

Narita M, Hatayama A, Hiroshi U (2007) Methods for preparing alkali cellulose and cellulose ether. US Patent 8:017–766

Xiao B, Sun XF, Sun R (2001) The chemical modification of lignins with succinic anhydride in aqueous systems. Polym Degrad Stabil 71(2):223–231

Dahou W, Ghemati D, Oudia A (2010) Preparation and biological characterization of cellulose graft copolymers. Biochem Eng J 48(2):187–194

Huang HC, Chen LC, Lin SB, Hsu CP, Chen HH (2010) In situ modification of bacterial cellulose network structure by adding interfering substances during fermentation. Bioresource Technolo 101(15):6084–6091

Wen HY, Li H, Xu SY, Xiao SL, Li HF, Jiang SC, An LJ, Wu ZH (2012) Shear effects on crystallization behavior of poly(ethylene-co-octene) copolymers. J Polym Res 19:1–12

Stevens MP (1999) Polymer chemistry. Oxford University Press, New York

Schwanninger M, Rodrigues JC, Pereira H, Hinterstoisser B (2004) Effects of short-time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib Spectrosc 36:23–40

Klug HP, Alexander LE (1974) X-ray diffraction procedures: for polycrystalline and amorphous materials. Wiley-VCH, New York

Navard P, Haudin JM, Quenin I, Peguy A (1986) Shear rheology of diluted solutions of high molecular weight cellulose. J Appl Polym Sci 32(7):5829–5839

Acknowledgements

Thanks for the financial assistance of Textile Vision Science & Education Fund of China and Postdoctoral Science Foundation of Shanghai (12R21410100).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, Y., Li, H., Li, X. et al. Green chemical preparation of cellulose/high performance elastomer blend fibers by melt-spinning method. J Polym Res 20, 171 (2013). https://doi.org/10.1007/s10965-013-0171-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-013-0171-z