Abstract

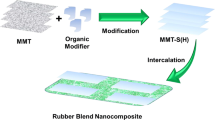

Montmorillonite clay (MMT) was modified by octadecylamine (ODA) or octadecyltrimethyl ammonium bromide (ODTMA) surfactants. The surfactant contents were varied, i.e. 0.5, 1.0 and 2.0 times the cation exchange capacity (CEC) of the MMT. The intercalation of surfactant molecules into MMT layers was confirmed by the increase in interlayer spacing of the modified MMT, the appearance of C-H stretching bands of alkyl ammonium surfactants and the increase in decomposition temperatures of the intercalated surfactant. With increasing surfactant content, the excess amounts of surfactant which had low interaction with MMT surface increased. The MMT-ODA and MMT-ODTMA were used as reinforcing fillers for natural rubber (NR). Effects of surfactant content and type on cure characteristics, tensile and morphological properties of NR nanocomposites were determined. NR nanocomposites containing 5 phr of the organoclays were prepared by a two-roll mill. With increasing surfactant content, morphologies of the NR nanocomposites revealed the exfoliated structure and the good dispersion of the organoclay in the NR matrix. These caused the enhancement of tensile properties of the NR nanocomposites. Among all the nanocomposites, NR/MMT-ODA2 had the highest tensile strength and provided optimum scorch time and cure time.

Similar content being viewed by others

References

Teh PL, Mohd-Ishak ZA, Hashim AS, Karger-Kocsis J, Ishiaku US (2004) Effects of epoxidized natural rubber as a compatibilizer in melt compounded natural rubber–organoclay nanocomposites. Eur Polym J 40:2513–2521

Arroyo M, Lopez-Manchado MA, Herrero B (2003) Organo-montmorillonite as substitute of carbon black in natural rubber compounds. Polymer 44:2447–2453

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of material. Mater Sci Eng 28:1–63

Magaraphan R, Thaijaroen W, Lim-ochakun R (2003) Structure and properties of natural rubber and modified montmorillonite nanocomposites. Rubber Chem Technol 76:406–418

Wibulswas R (2004) Batch and fixed bed sorption of methylene blue on precursor and QACs modified montmorillonite. Sep Purif Technol 39:3–12

Paiva LBD, Morales AR, Diaz FRV (2008) Organoclays: Properties, preparations and applications. Appl Clay Sci 42:8–24

Vaia R, Teukolsky RK, Giannelis EP (1994) Interlayer structure and molecular environment of alkylammonium layered silicates. Chem Mater 6:1017–1022

Ray SS, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processing. Prog Polym Sci 28:1539–1641

Marras SI, Tsimpliaraki A, Zuburtikudis I, Panayiotou C (2009) Morphological, thermal, and mechanical characteristics of polymer/layered silicate nanocomposites: The role of filler modification level. Polym Eng Sci 49:1206–1217

Keawkumay C, Jarukumjorn K, Suppakarn N (2010) Effects of surfactant content and clay content on properties of NR nanocomposites. Adv Mater Res 123–125:55–58

Flory PJ (1953) Principles of polymer chemistry. Cornell University Press, New York

Avalos F, Ortiz JC, Zitzumbo R, Lopez-Manchado MA, Verdejo R, Arroyo M (2008) Effect of montmorillonite intercalant structure on the cure parameters of natural rubber. Eur Polym J 44:3108–3115

Balachandram M, Bhagawan SS (2012) Mechanical, thermal and transport properties of nitrile rubber (NBR)-nanoclay composite. J Polym Res. doi:10.1007/s10965-011-9809-x

Xi Y, Ding Z, He H, Frost RL (2004) Structure of organoclays-an X-ray diffraction and thermogravimetric analysis study. J Colloid Interf Sci 277:116–120

Jaymand M (2011) Surface modification of montmorillonite with novel modifier and preparation of polystyrene/motmorillonite nanocomposite by in situ radical polymerization. J Polym Res 18:957–963

Kim MS, Kim DW, Chowdhury SR, Kim GH (2006) Melt-compounded butadiene rubber nanocomposites with improved mechanical properties and abrasion resistance. J Appl Polym Sci 102:2062–2066

Arroyo M, Lopez-Manchado MA, Valentin JL, Carretero J (2007) Morphology/behaviour relationship of nanocomposites based on natural rubber/epoxidized natural rubber blends. Compos Sci Technol 67:1330–1339

Kim W, Kang BS, Cho SG, Ha CS, Bae JW (2007) Styrene butadiene rubber-clay nanocomposites using a latex method: morphology and mechanical properties. Compos Interface 14:409–425

Zhang X, Loo LS (2008) Morphology and mechanical properties of a novel amorphous polyamide/nanoclay nanocomposite. J Polym Sci B Polym Phys 46:2605–2617

Acknowledgements

The authors are grateful to Suranaree University of Technology, the National Research Council of Thailand and the Office of the Higher Education Commission (Higher Education Research Promotion and National Research University Project of Thailand) for the financial supports and Thai Nippon Co., Ltd. for providing MMT.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Keawkumay, C., Jarukumjorn, K., Wittayakun, J. et al. Influences of surfactant content and type on physical properties of natural rubber/organoclay nanocomposites. J Polym Res 19, 9917 (2012). https://doi.org/10.1007/s10965-012-9917-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-012-9917-2