Abstract

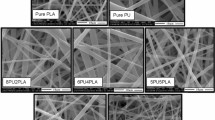

Polylactide (PLA) was mixed with poly(vinylidene fluoride) (PVDF) and spun into nonwoven mats via electrospinning technique using a co-solvent system of N,N-dimethylformamide (DMF) and acetone. The resulting mats were subject to characterization including contact angle, infrared spectrometry (IR), wide-angle X-ray diffraction (WAXD), differential scanning calorimetry (DSC), tensile test, and examined using scanning electron microscope (SEM). With such a co-solvent system, the viscosity was measured, and the average fiber diameter achievable without beads for PLA, PLA/PVDF, and PVDF mats was 252 nm, 209 nm, and 355 nm, respectively. Infrared spectra showed that electrospinning can induce crystallization of PVDF. Both α and β phases were observed from the IR and WAXD results. From the results of DSC, the PLA/PVDF mats exhibited higher melting temperature but lower crystallinity than both PLA and PVDF. The tensile strength of PLA/PVDF was lower than those of PLA and PVDF. By applying stretching during eletrospinning, the ratio of strength in machine direction (MD) to that in cross direction (CD) was increased to 2. In addition, electrospun PLA/PVDF mats exhibited higher cell proliferation for L929 fibroblasts than both PLA and PVDF mats.

Similar content being viewed by others

References

Li D, Xia Y (2004) Adv Mater 16(14):1151. doi:10.1002/adma.200400719

Wong SC, Baji A, Leng S (2008) Polymer 49:4713. doi:10.1016/j.polymer.2008.08.022

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S (2003) Compos Sci Technol 63:2223. doi:10.1016/S0266-3538(03)00178-7

You Y, Min BM, Lee SJ, Lee TS, Park WH (2005) J Appl Polym Sci 95:193. doi:10.1002/app. 21116

Ramdhanie LI, Aubuchon SR, Boland ED, Knapp DC, Barnes CP, Simpson DG, Wnek GE, Bowlin GL (2006) Polym J 38(11):1137. doi:10.1295/polymj.PJ2006062

Kenawy ER, Bowlin GL, Mansfield K, Layman J, Simpson DG, Sanders EH, Wnek GE (2002) J Control Release 81:57. doi:10.1016/S0168-3659(02)00041-X

Zong X, Bien H, Chung CY, Yin L, Fang D, Hsiao BS, Chu B, Entcheva E (2005) Biomaterials 26:5330. doi:10.1016/j.biomaterials.2005.01.052

Zong X, Kim K, Fang D, Ran S, Hsiao BS, Chu B (2002) Polymer 43:4403. doi:10.1016/S0032-3861(02)00275-6

Sun B, Duan B, Yuan X (2006) J Appl Polym Sci 102:39. doi:10.1002/app. 24297

Iwatake A, Nogi M, Yano H (2008) Compos Sci Technol 68:2103. doi:10.1016/j.compscitech.2008.03.006

You Y, Lee SW, Lee SJ, Park WH (2006) Mater Lett 60:1331. doi:10.1016/j.matlet.2005.11.022

RJr G (2006) J Appl Polym Sci 100:3272. doi:10.1002/app. 23137

Zhao Z, Li J, Yuan X, Li X, Zhang Y, Sheng J (2005) J Appl Polym Sci 97:466. doi:10.1002/app. 21762

Koombhongse S, Liu W, Reneker DH (2001) J Polym Sci Polym Phys 39:2598. doi:10.1002/polb.10015

Mazzei R, Smolko E, Tadey D, Gizzi L (2000) Nucl Instrum Methods B 170:419. doi:10.1016/S0168-583X(00)00243-3

Chen MH, Hsu YH, Lin CP, Chen YJ, Young TH (2005) J Biomed Mater Res 74:254. doi:10.1002/marc.200700544

Rodrigues MT, Gomes ME, Mano JF, Reis RL (2008) Mat Sci Forum 587:72

Liu TY, Lin WC, Huang LY, Chen SY, Yang MC (2005) Polym Adv Technol 16:413. doi:10.1002/pat.592

Zheng J, He A, Li J, Han CC (2007) Macromol Rapid Commun 28:2159. doi:10.1002/marc.200700544

Yee WA, Kotaki M, Liu Y, Lu X (2007) Polymer 48:512. doi:10.1016/j.polymer.2006.11.036

Chen Y, Kim H (2009) Appl Surf Sci 255(15):7073. doi:10.1016/j.apsusc.2009.03.043

Zheng Z, Gu Z, Huo R, Ye Y (2009) Appl Surf Sci 255(16):7263. doi:10.1016/j.apsusc.2009.03.084

Tsuji H, Nakano M, Hashimoto M, Takashima K, Katsura S, Mizuno A (2006) Biomacromolecules 7:3316. doi:10.1021/bm060786e

Jiang L, Wolcott MP, Zhang J (2006) Biomacromolecules 7:199. doi:10.1021/bm050581q

Inai R, Kotaki M, Ramakrishna S (2005) Nanotechnology 16:208. doi:10.1088/0957-4484/16/2/005

Nasir M, Matsumoto H, Danno T, Minagawa M, Irisawa T, Shioya H, Tanioka A (2006) J Polym Sci Polym Phys 44:779. doi:10.1002/polb.20737

Zeng J, Chen X, Liang Q, Xu X, Jing X (2004) Macromol Biosci 4:1118. doi:10.1002/mabi.200400092

Inai R, Kotaki M, Ramakrishna S (2005) J Polym Sci Polym Phys 43:3205. doi:10.1002/polb.20457

Shin YM, Hohman MM, Brenner MP, Rutledge GC (2001) Polymer 42:9955. doi:10.1016/S0032-3861(01)00540-7

Hooqsteen W, Postema AR, Penninqs AJ, Brinke G, Zuqenmaier P (1990) Macromolecules 23:634

Zhang G, Zhang J, Wang S, Shen D (2003) J Polym Sci Polym Phys 41:23. doi:10.1002/polb.10353

Li Y, Shimizu H (2007) Macromol Biosci 7:921. doi:10.1002/mabi.200700027

Sung HW, Chen CN, Huang RN, Hsu JC, Chang WH (2000) Biomaterials 21:1353. doi:10.1016/S0142-9612(00)00017-X

Li W, Laurencin CT, Cateson EJ, Tuan RS, Ko FK (2002) J Biomed Mater Res 60:613. doi:10.1002/jbm.10167

Chen M, Patra PK, Warner SB, Bhowmick S (2007) Tissue Eng 13(3):579. doi:10.1089/ten.2006.0205

Nagahama K, Nishimura Y, Ohya Y, Ouchi T (2007) Polymer 48(9):2649. doi:10.1016/j.polymer.2007.03.017

Park A, Cima LG (1996) J Biomed Mater Res 31:117. doi:10.1002/jbm.1996.820310102

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, HC., Tsai, CH. & Yang, MC. Mechanical properties and biocompatibility of electrospun polylactide/poly(vinylidene fluoride) mats. J Polym Res 18, 319–327 (2011). https://doi.org/10.1007/s10965-010-9421-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9421-5