Abstract

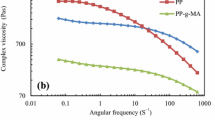

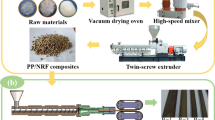

Microfibrillar-reinforced composites based on two dispersed phases, liquid crystalline polymer (LCP) and recycled poly(ethylene terephthalate) (rPET), and polystyrene (PS) were prepared using extrusion process. The rheological behavior, morphology, and thermal stability of LCP/PS and rPET/PS blends containing various dispersed phase contents were investigated. All blends and LCP exhibited shear thinning behavior, whereas Newtonian fluid behavior was observed for rPET. The incorporation of both LCP and rPET into PS significantly improved the processability. The potential of rPET as a processing lubricant by bringing down the melt viscosity of the blend system was as good as LCP. The elongated LCP domains were clearly observed in as-extruded strand. Although the viscosity ratio of rPET/PS system was lower than that of LCP/PS system, most rPET domains appeared as small droplets. An addition of LCP and rPET into PS matrix improved the thermal resistance in air significantly. The obtained results suggested the high potential of rPET as a processing aid and thermally stable reinforcing-material similar to LCP. The mechanical properties of the LCP-containing blends were mostly higher than those of the corresponding rPET-containing blends when compared at the same blend composition.

Similar content being viewed by others

References

Kiss G (1987) Polym Eng Sci 27:410

Tjong S (2003) Mater Sci Eng R41:1

Dutta D, Fruitwala H, Kohli A, Weiss RA (1990) Polym Eng Sci 30:1005

Pawlikowski GT, Dutta D, Weiss RA (1991) Annu Rev Mater Sci 21:159

Friedrich K, Evstatiev M, Farikov S, Evstatiev O, Ishii M, Harrass M (2005) Compos Sci Technol 65:107 doi:10.1016/j.compscitech.2004.06.008

Kalfoglou NK, Skafidas DS, Sotiropoulou DD (1994) Polymer (Guildf) 35:3624 10.1016/0032–3861(94)90538-X

Aglietto M, Coltelli MB, Savi S, Lochiatto F, Ciardelli F, Giani M (2004) J Mater Cycles Waste Manag 6:13

Taepaiboon P, Junkasem J, Dungtungee R, Amornsakchai T, Supaphol P (2006) J Appl Polym Sci 120:1173 doi:10.1002/app.24402

Fuchs C, Bhattacharyya D, Fakirov S (2006) Compos Sci Technol 66:3161 doi:10.1016/j.compscitech.2005.02.023

Santos P, Pezzin SH (2003) J Mater Process Technol 143–144:517 doi:10.1016/S0924-0136(03)00391-1

Evstatiev M, Fakirov S, Krasteva B, Friedrich K, Covas JA, Cunha AM (2002) Polym Eng Sci 42:826

Pawlak A, Morawiec J, Pazzagli F, Pracella M, Galeski A (2002) J Appl Polym Sci 86:1473 doi:10.1002/app.11307

Ávila AF, Duarte MV (2003) Polym Degrad Stabil 80:373 10.1016/S0141–3910(03)00025–9

Zhang H, Guo W, Yu Y, Li B, Wu C (2007) Eur Polym J 43:3662 doi:10.1016/j.eurpolymj.2007.05.001

Evstatiev M, Fakirov S (1992) Polymer (Guildf) 33:877 doi:10.1016/0032-3861(92)90354-Y

Ju MY, Chang FC (2000) Polymer (Guildf) 41:1719 doi:10.1016/S0032-3861(99)00355-9

Maa CT, Chang FC (1993) J Appl Polym Sci 49:913 doi:10.1002/app.1993.070490517

Hsieh TT, Tiu C, Hsieh KH, Simon GP (2000) J Appl Polym Sci 77:2319 doi:10.1002/1097-4628(20000906)77:10<2319::AID-APP26>3.0.CO;2-#

Isayev AI, Modic M (1987) Polym Compos 8:158 doi:10.1002/pc.750080305

Blizard KG, Baird DG (1987) Polym Eng Sci 27:653

Mehta A, Isayev AI (1991) Polym Eng Sci 3:963

Verhoogt H, Willems CRJ, Van Dam J, De Boer AP (1993) Polym Eng Sci 33:754

Saikrasun S, Bualek-Limcharoen S, Kohjiya S, Urayama K (2003) J Appl Polym Sci 89:2676 doi:10.1002/app.12385

Saikrasun S, Amornsakchai T (2006) J Appl Polym Sci 101:1610 doi:10.1002/app.23564

Seo Y, Kim KU (1998) Polym Eng Sci 38:596

Postema AR, Fenis PJ (1997) Polymer (Guildf) 38:5557 doi:10.1016/S0032-3861(97)00099-2

Chan CK, Whitehouse C, Gao P, Chai CK (1997) Polymer (Guildf) 42:7847 doi:10.1016/S0032–3861(01)00265–8

Jang BN, Wilkie CA (2005) Polymer (Guildf) 46:2933 doi:10.1016/j.polymer.2005.01.098

Peterson JD, Vyazovkin S, Wight AA (2001) Macromol Chem Phys 202:775 doi:10.1002/1521-3935(20010301)202:6<775::AID-MACP775>3.0.CO;2-G

Saikrasun S, Wongkalasin O (2005) Polym Degrad Stabil 88:300 doi:10.1016/j.polymdegradstab.2004.11.004

Sato H, Kikuchi T, Koide N, Furuya K (1996) J Appl Pyrolysis 37:173 doi:10.1016/0165-2370(96)00944-8

Saikrasun S, Amornsakchai T (2008) J Appl Polym Sci 107:2375 doi:10.1002/app.27092

Girija BG, Sailaja RRN, Madras G (2005) Polym Degrad Stabil 90:147 doi:10.1016/j.polymdegradstab.2005.03.003

Villain P, Coudane J, Vert M (1995) Polym Degrad Stabil 49:393 doi:10.1016/0141-3910(95)00121-2

Dzieciol M, Trzeszczynski JJ (1998) Appl Polym Sci 69:2377 doi:10.1002/(SICI)1097-4628(19980919)69:12<2377::AID-APP9>3.0.CO;2–5

Li XG, Huang MR, Guan GH, Sun T (1998) Polym Int 46:289 doi:10.1002/(SICI)1097-0126(199808)46:4<289::AID-PI993>3.0.CO;2-O

Acknowledgements

The authors gratefully acknowledge the financial support by the Office of Commission on Higher Education and Thailand Research Fund (contract grant number, MRG5080415). Financial support from Center of Excellence for Innovation in Chemistry is also gratefully acknowledged. Finally, the authors would like to thank Professor Sauvarop Bualek-Limcharoen for the gift of Rodrun LC3000 liquid crystalline polymer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saikrasun, S., Limpisawasdi, P. & Amornsakchai, T. Comparative study on phase and properties between rPET/PS and LCP/PS in situ microfibrillar-reinforced composites. J Polym Res 16, 443–454 (2009). https://doi.org/10.1007/s10965-008-9247-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-008-9247-6