Abstract

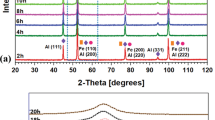

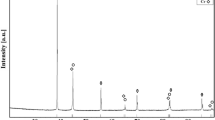

This study involves the synthesis of nanocrystalline Fe90Nb10 (wt.%) binary powders through the use of a high-energy planetary ball mill within an inert argon environment. The milling process was used to investigate changes in structure, morphology, and magnetic properties. This was accomplished through the utilization of techniques including employing the MAUD program for X-ray diffraction, utilizing the Rietveld method, employing scanning electron microscopy (SEM), utilizing energy dispersive X-ray (EDX) analysis, and employing vibrating sample magnetometry. From the X-ray diffraction (XRD) analysis, it was observed that a disordered solid solution of α-Fe(Nb) with a body-centered cubic (bcc) crystal structure formed after 12 h of milling. Interestingly, the analysis also indicated that the average crystallite size < D > within this α-Fe(Nb) solid solution was remarkably small, measuring a mere 13 nm. Furthermore, the ultimate lattice strain < σ2 > 1/2 was quantified at 1.08%. It is worth noting that the lattice parameter underwent a rapid and substantial increase from 0.2871 to 0.2879 nm after 36 h of milling. The SEM analyses revealed the development of diverse morphologies at different milling stages. The EDX experiments validating the outcomes observed through XRD revealed elemental maps of Fe and Nb. These results corroborated the evolution of alloy formation. The study also explored variations in saturation magnetization (Ms), coercive field (Hc), remanent magnetization (Mr), and squareness ratio (Mr/Ms) in connection with microstructural modifications during the milling process.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article.

References

Kang, I., Yang, J., Lee, W., Seo, E.Y., Lee, D.H.: Delineating development trends of nanotechnology in the semiconductor industry: focusing on the relationship between science and technology by employing structural topic model. Technol. Soc. 74, 102326 (2023). https://doi.org/10.1016/j.techsoc.2023.102326

Schummer, J.: Multidisciplinarity, interdisciplinarity, and patterns of research collaboration in nanoscience and nanotechnology. Scientometrics 59(3), 425–465 (2004). https://doi.org/10.1023/B:SCIE.0000018542.71314.38

Islam, N., Miyazaki, K.: Nanotechnology innovation system: understanding hidden dynamics of nanoscience fusion trajectories. Technol. Forecast. Soc. Change. 76(1), 128–140 (2009). https://doi.org/10.1016/j.techfore.2008.03.021

Wang, A.P., Hou, C.E., Hung, S.W.: Exploration of the evolution of nanotechnology from a patent co-classification perspective. Nanotechnol. 7(3), 233–245 (2018). https://doi.org/10.1515/ntrev-2018-0005

Zhanga, Y.H., Wuc, L.R., Maa, J., Cui, G.: Nanotechnology in solid state batteries, what’s next? Next Nanotechnology. 2, 100011 (2023). https://doi.org/10.1016/j.nxnano.2023.100011

Guemmoud, N., Hafs, A., Hafs, T.: Effect of milling time on the structural, microstructure, and magnetic properties of nanocrystalline Fe90Sb10 powders obtained by high-energy ball milling. Int. J. Adv. Manuf. Technol. 122, 2043–2058 (2022). https://doi.org/10.1007/s00170-022-10003-x

Behvandi, A., Shokrollahi, H., Chitsazan, B., Ghaffari, M.: Magnetic and structural studies of mechanically alloyed nanostructured Fe49Co49V2 powders. J. Magn. Magn. Mater. 322, 3932–3937 (2010). https://doi.org/10.1016/j.jmmm.2010.08.025

Hasnaouia, N., Hafs, A., Hafs, T., Bendjedaa, F.: Structural, microstructural characterisation and magnetic properties of nanocrystalline Fe-10 wt% Pb alloy powders synthesized by mechanical alloying process. J. Alloys Compd. 899, 163338 (2022). https://doi.org/10.1016/j.jallcom.2021.163338

Ibn Gharsallah, H., Azabou, M., Escoda, L., Suñol, J.J., Lopez, I., Llorca-Isern, N., Khitouni, M.: The magnetic and structural properties of nanostructured (Fe75Al25)100-xBx alloys prepared by mechanical alloying. J Alloys Compd. 729, 776–786 (2017). https://doi.org/10.1016/j.jallcom.2017.09.229

Wederni, A., Lachheb, R., Suñol, J.J., Saurina, J., Escoda, L., Khitouni, M.: Structural, microstructural and thermal properties of nanostructured Fe60Al35Sn5 alloy synthesized by mechanical alloying. Mater Charact 148, 272–279 (2019). https://doi.org/10.1016/j.matchar.2019.01.001

Khelfa, T., Mhadhbi, M., Khitouni, N., Bachagha, T., Suñol, J.J., Khitouni, M.: Effect of high-energy ball milling on the structural and magnetic behavior of Fe60Al40 alloy. J. Mater. Eng. Perform. (2023). https://doi.org/10.1007/s11665-023-08438-8

Suñol, J.J., Escoda, L., Fort, J., Pérez, J., Pujol, T.: Structural and magnetic properties of a nanocrystalline Fe75Nb10Si5B10 alloy produced by mechanical alloying. Mater. Lett. 62, 1673–1676 (2008). https://doi.org/10.1016/j.matlet.2007.09.057

Lachheb, R., Bachaga, T., Khitouni, M., Makhlouf, T.: Transformations de phase et propriétés microstructurales du Fe nanocristallin75Si10B10Nb5 Alloy Synthesized by Mechanical Alloying. Adv. Powder Technol. 26, 1563–1569 (2015). https://doi.org/10.1016/j.apt.2015.08.010

Aththanayaka, S., Thiripuranathar, G., Ekanayake, S.: Emerging advances in biomimetic synthesis of nanocomposites and potential applications. Materials Today Sustainability 20, 100206 (2022). https://doi.org/10.1016/j.mtsust.2022.100206

Khan, N., Ali, S., Latif, S., Mehmood, A.: Biological synthesis of nanoparticles and their applications in sustainable agriculture production. Nat. Sci. 14, 226–234 (2022). https://www.scirp.org/journal/ns

Saleh, H.M., Hassan, A.I.: Synthesis and characterization of nanomaterials for application in cost-effective electrochemical devices. Sustainability. 15(14), 10891 (2023). https://doi.org/10.3390/su151410891

Ibn Gharsallah, H., Makhlouf, T., Saurina, J., Escoda, L., Suñol, J.J., Llorca-Isern, N., Khitouni, M.: Effect of boron addition on structural and magnetic properties of nanostructured Fe75Al25 alloy prepared by high energy ball milling. Mater. Lett. 181, 21–24 (2016). https://doi.org/10.1016/j.matlet.2016.05.190

Pradeep, N.B., Rajath Hegde, M.M., Rajendrachari, S., Surendranathan, A.O.: Investigation of microstructure and mechanical properties of microwave consolidated TiMgSr alloy prepared by high energy ball milling. Powder Technology. 408,(2022). https://doi.org/10.1016/j.powtec.2022.117715

Prathap, S., Madhuri, W., Meena, S.S.: Multiferroic properties and Mössbauer study of M-type hexaferrite PbFe12O19 synthesized by the high energy ball milling. Mater Charact 177, 111168 (2021). https://doi.org/10.1016/j.matchar.2021.111168

Suryanarayana, C.: Mechanical alloying and milling. Prog. Mater. Sci. 46(1–2), 1–184 (2001). https://doi.org/10.1016/S0079-6425(99)00010-9

Kushwaha, A.K., John, M., Misra, M., Menezes, P.L.: Nanocrystalline materials: synthesis, characterization, properties, and applications. Crystals 11, 1317 (2021). https://doi.org/10.3390/cryst11111317

Bhoi, B., Srinivas, V., Singh, V.: Evolution of microstructure and magnetic properties of nanocrystalline Fe70-xCuxCo30 alloy prepared by mechanical alloying. J. Alloys Compd. 496(1–2), 423–428 (2010). https://doi.org/10.1016/j.jallcom.2010.01.155

Suryanarayana, C.: Structure and properties of nanocrystalline materials. Bull. Mater. Sci. 17(4), 307–346 (1994). https://doi.org/10.1007/BF02745220

Kransnowski, M., Kulik, T.: Bulk amorphous and nanocrystalline Al83Fe17 alloys prepared by consolidation of mechanically alloyed amorphous powder. J. Alloys Compd. 495, 382–385 (2010). https://doi.org/10.1016/j.jallcom.2009.10.177

Azabou, M., Khitouni, M., Kolsi, A.: Characterization of nanocrystalline Al-based alloy produced by mechanical milling followed by cold-pressing consolidation. Mater Charact 60, 499–505 (2009). https://doi.org/10.1016/j.matchar.2008.12.016

Ji, G., Goran, D., Bernard, F., Grosdidier, T., Gaffet, E., Munir, Z.A.: Structure and composition heterogeneity of a FeAl alloy prepared by one-step synthesis and consolidation processing and their influence on grain size characterization. J. Alloys Compd. 420, 158–164 (2006). https://doi.org/10.1016/j.jallcom.2005.10.058

Ibrahim, I.D., Sadiku, E.R., Jamiru, T., Hamam, Y., Alayli, Y., Eze, A.A.: Prospects of nanostructured composite materials for energy harvesting and storage. J. King. Saud. Univ. Sci. 32(1), 758–764 (2020). https://doi.org/10.1016/j.jksus.2019.01.006

Jartych, E., Oleszak, D., Żurawicz, J.K.: Hyperfine interactions in amorphous Fe–Nb alloys prepared by mechanical alloying. Hyperfine Interact. 136, 25–33 (2001). https://doi.org/10.1023/A:1015550913839

Schanzer, M., Mehrer, H.: Amorphization of Nb-Tm SysteM_s by mechanical alloying of the pure metals. J. Phys. (Paris) Colloq. 51, 87–93 (1990). https://doi.org/10.1051/jphyscol:1990410

Yang, J.Y., Zhang, T.J., Cui, K., Li, X.G., Zhang, J.: Amorphization of Fe-Nb by mechanical alloying. J. Alloys Compd. 242, 153–156 (1996). https://doi.org/10.1016/0925-8388(96)02320-1

Bortolotti, M., Lutterotti, L., Pepponi, G.: Combining XRD and XRF analysis in one rietveld-like fitting. Powder Diffr. 32(S1), S225–S230 (2017). https://doi.org/10.1017/S0885715617000276

Young, R.A., Wiles, D.B.: Profile shape functions in Rietveld refinements. J. Appl. Cryst. 15, 430–438 (1982). https://doi.org/10.1107/S002188988201231X

Avar, B., Gogebakan, M., Ozcan, S., Kerli, S.: Structural, mechanical and magnetic properties of Fe—40-at % Al powders during mechanical alloying. J. Kor. Phys. Soc. 65, 664–670 (2014). https://doi.org/10.3938/jkps.65.664

Hadef, F., Ans, M.: X-ray analysis and Rietveld refinement of ball milled Fe50Al35Ni15 powder. Surf. Interfaces. 26, 101303 (2021). https://doi.org/10.1016/j.surfin.2021.101303

Williamson, G.K., Smallman, R.E.: Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag: J. Theor. Exp. Appl. Phys. 1(1), 34–46 (1956). https://doi.org/10.1080/14786435608238074

Smallman, R.E., Westmacott, K.H.: Stacking faults in face-centered cubic metals and alloys, The Philosophical Magazine: A Journal of Theoretical Experimental and Applied. Physics 2(17), 669–683 (1957). https://doi.org/10.1080/14786435708242709

Freeman, L.C., Romney, A.K., Freeman, S.C.: Cognitive structure and informant accuracy. Am. Anthropol. 89(2), 310–325 (1987). https://www.jstor.org/stable/677757

Pękała, M., Pękała, K., Szydłowsk, J., Drozd, V.: Magnetic field induced evolution of highly resistant Griffiths phase in fine grain manganite La0.75Ca0.25MnO3. J. Magn. Magn. Mater 475, 189–194 (2019). https://doi.org/10.1016/j.jmmm.2018.11.069

Hamzaoui, R., Elkedim, O., Fenineche, N., Gaffet, E., Craven, J.: Structure and magnetic properties of nanocrystalline mechanically alloyed Fe–10% Ni and Fe–20% Ni. Mater. Sci. Eng. A 360, 299–305 (2003). https://doi.org/10.1016/S0921-5093(03)00460-X

Zeng, Q., Baker, I., McCreary, V., Yan, Z.: Soft ferromagnetism in nanostructured mechanical alloying FeCo-based powders. J. Magn. Magn. Mater. 318, 28–38 (2007). https://doi.org/10.1016/j.jmmm.2007.04.037

Herzer, G.: Nanocrystalline soft magnetic materials. Phys. Scr. 49, 307 (1993). https://doi.org/10.1088/0031-8949/1993/T49A/054

Taghvaei, A.H., Stoica, M., Khoshkhoo, M.S., Thomas, J., Vaughan, G., Ghaffari, M., Janghorban, K., Eckert, J.: Microstructure and magnetic properties of amorphous/nanocrystalline Co40Fe22Ta8B30 alloy produced by mechanical alloying. Mater. Chem. Phys. 134, 1214–1224 (2012). https://doi.org/10.1016/j.matchemphys.2012.04.031

Loudjani, N., Bensebaa, N., Dekhil, L., Alleg, S., Sunol, J.J.: Structural and magnetic properties of Co50Ni50 powder mixtures. J. Magn. Magn. Mater. 323, 3063–3070 (2011). https://doi.org/10.1016/j.jmmm.2011.06.059

Azzaza, S., Alleg, S., Moumeni, H., Nemamcha, A.R., Rehspringer, J.L., Greneche, J.M.: Phase transformation in the ball milled Fe31Co31Nb8B30 powders. J. Phys. Condens. Matter. 18, 7257–7272 (2006). https://doi.org/10.4236/ampc.2013.31A011

Bensebaa, N., Loudjani, N., Alleg, S., Dekhil, L., Sunol, J.J., Al Sae, M., Bououdina, M.: XRD analysis and magnetic properties of nanocrystalline Ni20Co80 alloys. J. Magn. Magn. Mater. 349, 51–56 (2014). https://doi.org/10.1016/j.jmmm.2013.08.045

Avar, B., Ozcan, S.: Characterization and amorphous phase formation of mechanically alloyed Co60Fe5Ni5Ti25B5 powders. J. Alloy. Compd. 650, 53–58 (2015). https://doi.org/10.1016/j.jallcom.2015.07.268

Loudjani, N., Gouasmia, T., Bououdina, M., Bobet, J.L.: Phase formation and magnetic properties of nanocrytalline Ni70Co30 alloy prepared by mechanical alloying. J. Alloy. Compd. 846, 156392 (2020). https://doi.org/10.1016/j.jallcom.2020.156392

Acknowledgements

The authors warmly thank the members of group L3M-Annaba, Dr. S. Leboub, M. Mittri, and H. Zedouri, for making SEM and EDX studies. This work was supported by the Algerian Directorate for Scientific Research and Technological Development (DGRSDT).

Author information

Authors and Affiliations

Contributions

AH: synthesis and characterizations, validation, investigation, resources, writing—original draft, writing—review and editing, visualization. TH: conception, methodology, resources, review and editing, visualization, supervision, validation. DB: XRD measurements and database, interpretation of results, manuscript preparation, visualization. LY: validation, writing—review and editing, visualization. NH: XRD refinement, visualization.

Corresponding author

Ethics declarations

Competing Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hafs, A., Hafs, T., Berdjane, D. et al. Magnetic Properties, Phase Evolution, and Microstructure of Fe90Nb10 Powder Mixtures. J Supercond Nov Magn (2024). https://doi.org/10.1007/s10948-024-06740-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10948-024-06740-7