Abstract

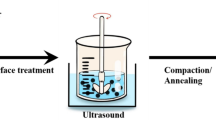

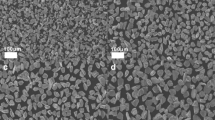

Fe-6.5wt%Si soft magnetic powder cores were prepared by using an improved bluing insulation method. A high-quality oxide insulation layer with good temperature stability was found to distribute continuously in the intervals between the Fe–Si particles. The effects of the annealing temperature and the compaction pressure on the core’s magnetic properties were investigated in detail. It was found that high temperature and low compaction pressure are beneficial to decrease the core’s inner stress and high compaction pressure is helpful to reduce the air gap. All the variations of the magnetic performance for the powder cores discussed in this paper were explained reasonably by considering these two factors. From the point of view of low loss, 760 °C and 2090 MPa were confirmed to be the relatively best annealing temperature and compaction pressure, respectively. The μ e , the % μ e at 100 Oe, and the loss at 50 kHz/1000 Gs for the core prepared under these two conditions are 63.57, 72.82%, and 547.66 mW/cm3, respectively.

Similar content being viewed by others

References

Ding, W., Jiang, L., Liao, Y., Song, J., Li, B., Wu, G.: J. Magn. Magn. Mater. 378, 232–238 (2015)

Wu, Z.Y., Fan, X.A., Wang, J., Li, G.Q., Gan, Z.H., Zhang, Z.: J. Alloys Comput. 617, 21–28 (2014)

Fan, X.A., Wang, J., Wu, Z.Y., Li, G.Q.: Mater. Sci. Eng. B 201, 79–86 (2015)

Sunday, K.J., Hanejko, F.G., Taheri, M.L.: J. Magn. Magn. Mater. 423, 164–170 (2017)

Huang, M.Q., Wu, C., Jiang, Y.Z., Yan, M.: J. Alloys Comput. 644, 124–130 (2015)

Dong, S.J., Song, B., Zhang, X.F., Deng, C., Fenineche, N., Hansz, B., Liao, H., Coddet, C.: J. Alloys Comput. 584, 254–260 (2014)

Lu, X.G., Liang, G.Y., Sun, Q.J., Yang, C.H.: J. Alloys Comput. 509, 5079–5083 (2011)

Strečková, M., Medvecký, L’., Füzer, J., Kollár, P., Bureš, R., Fáberová, M.: Mater. Lett. 101, 37–40 (2013)

Xie, D.Z., Lin, K.H., Lin, S.T.: J. Magn. Magn. Mater. 353, 34–40 (2014)

Li, Z.C., Dong, Y.Q., Pauly, S., Chang, C.T., Wei, R., Li, F.S., Wang, X.M.: J. Alloys Comput. 706, 1–6 (2017)

Zhao, G.L., Wu, C., Yan, M.: J. Alloys Comput. 685, 231–236 (2016)

Peng, Y.D., Yi, Y., Li, L.Y., Yi, J.H., Nie, J.W., Bao, C.X.: Mater. Des. 109, 390–395 (2016)

Olekšáková, D., Füzer, J., Kollár, P., Roth, S.: J. Magn. Magn. Mater. 333, 18–21 (2013)

Peng, Y.D., Yi, Y., Li, L.Y., Ai, G., Wang, X.X., Chen, L.L.: J. Magn. Magn. Mater. 428, 148–153 (2017)

Schwindt, V.C., Ardenghi, J.S., Bechithold, P., Juan, A., Batic, B.S., Jenko, M., Gonzalez, E.A., Jasen, P.V.: Appl. Surf. Sci. 354, 401–407 (2015)

Wang, X.Y., Lu, C.W., Guo, F., Lu, Z.C., Li, D., Zhou, S.X.: J. Magn. Magn. Mater. 324, 2727–2730 (2012)

Yang, B., Wu, Z.B., Zhou, Z.Y., Yu, R.H.: J. Phys. D: Appl. Phys. 43, 365003–365008 (2010)

Kim, Y.W., Choi, KC, Chung, Y.S., Choi, E., Nam, T.H.: J. Alloys Comput. 577S, S227–S231 (2013)

Liu, H.J., Su, H.L., Geng, W.B., Sun, Z.G., Song, T.T., Tong, X.C., Zou, Z.Q., Wu, Y.C., Du, Y.W.: J. Supercond. Nov. Magn. 29, 463–468 (2016)

Funding

This work was supported by the Fundamental Research Funds for the Central Universities (No. JZ2016YYPY0055) and State Grid Jiangsu Power Company Science and Technology Project (No. J2017048).

Author information

Authors and Affiliations

Corresponding author

Additional information

Z. Zhang and P. Wu contributed equally to this work.

Rights and permissions

About this article

Cite this article

Zhang, Z., Wu, P., Han, S.J. et al. Effects of Annealing Temperature and Compaction Pressure on Magnetic Properties of Fe–Si Powder Cores Fabricated by an Improved Bluing Method. J Supercond Nov Magn 31, 1507–1513 (2018). https://doi.org/10.1007/s10948-017-4358-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-017-4358-0