Abstract

The (Bi1−x Pb x )2Sr 2Ca 2Cu 3 O y (x = 0.2, 0.4) films were obtained directly on silver substrates by the sedimentation process. The temperature dependencies of the AC susceptibility of the films and bulk materials were measured and analyzed. The critical temperatures of the grains T cg as well as the Josephson junctions T cJ of these films were obtained from the dispersion part of AC susceptibility and they are T cg = 106.5 K, T cJ = 100.2, T cg = 106.1 K, and T cJ = 97 K, respectively. The thickness of these films is of the order of a hundred micrometers. The critical currents were derived from the absorption part of AC susceptibility using the Bean’s critical state model. The temperature dependencies of the critical currents were analyzed using the Ginzburg–Landau strong coupling limit approach.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The high-temperature superconductor (HTS) films are very important for large-scale applications including electrical motors, generators, power transmission cables, transformers, magnets, superconducting magnetic energy storage devices, and others. Extensive investigations of the films have also been connected with optimization of the fabrication and processing techniques of HTS wires and tapes.

Silver is typically used as a substrate for superconducting material in superconducting tapes and wires of yttrium [1, 2], thallium [3, 4] and bismuth-based [5, 6] hightemperature superconductors. The direct deposition of superconducting films on silver substrates without any buffer layer is one of the promising and low-cost methods of production of the superconducting tapes [7]. Silver turns out to be the only metal on which superconducting materials can be deposited without buffer layers because it does not react with them and can fill the pores and empty spaces between the grains [8–10].

In this paper, the results of AC susceptibility measurements of the BSCCO bulk materials as well as the films deposited directly on silver substrates using the low-cost sedimentation process are presented. From the temperature dependencies of the absorption part of AC susceptibility the critical current densities were calculated using the Bean’s critical state model.

2 Experimental

Polycrystalline (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y and (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y samples were prepared by the standard powder solid-state reaction technique. Appropriate amounts of highly pure Bi 2 O 3, CaCO 3, CuO, PbO, and SrCO 3 powders were thoroughly ground up in the agate mortar and calcinated at 820 ∘C for 30 h, then reground and sintered at 850 ∘C for 160 h. The grounding and sintering steps were repeated twice. Before the last sintering, the samples were pressed with the pressure of 0.4 GPa into the shape of pellets. After, the thermal treatment the pellets were reground and the powder obtained was mixed with the isopropanol alcohol in a glass vessel and ultrasonicated. The polished silver substrates were placed at the bottom of the glass vessel. After evaporation of the alcohol the powder deposited on the silver substrates was pressed against the substrate with the pressure of 0.4 GPa. The films were put together into the furnace and sintered at 840 ∘C for 2 h and then cooled down slowly to the room temperature. The thickness of the films was measured using XRF spectrometer and they were found to be 137 μm for (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y and 195 μm for (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y . The thickness of the bulk (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y and (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y samples in the form of pellets was measured by the micrometer screw gauge and they are 1.80 and 1.74 mm, respectively. The x-ray diffraction (XRD) measurement of the powder sample was carried out with the Empyrean Panalytical diffractometer (CuK α radiation). The data were collected at 300 K in the angular range 2–100 ∘ (2 𝜃) with steps of 0.016 ∘. The diffractogram was analysed using FULLPROF computer program based on Rietveld method [11]. The analysis of the x-ray diffraction patterns revealed the presence of two superconducting phases: the dominant (79.4 %) superconducting 2223 phase and minor (11.7 %) 2212 phase as well as a non conducting Ca 2PbO 4 phase (8.9 %). The dispersion χ ′ and absorption χ ″ parts of AC susceptibility for the AC magnetic field amplitudes ranging from 0.048 to 10.9 Oe were measured as a function of temperature by a standard mutual inductance bridge operating at the frequency of 189 Hz. A Standford Research System SR830 DSP lock-in amplifier served both as a source for the AC current for the coil producing the AC magnetic field and as a voltmeter of the bridge. The temperature was monitored by the Lake Shore Model 330 autotuning temperature controller employing chromel-gold—0.07 % Fe thermocouple with the accuracy of 0.05 K for this experimental setup. The magnetic field was applied parallel to the surface of the films and to the surface plane of the rectangular prism cut from the pellets.

3 Results

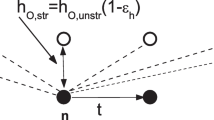

The AC susceptibility measurements of the bulk superconductors (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y and (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y that were used to prepare the films are shown in Figs. 1 and 2, respectively. The AC susceptibility measurements of (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y and (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y films deposited on the silver substrates are shown in Figs. 3 and 4. For the bulk and the thin film samples, one can notice that the intra-grain as well as inter-grain (Josephson junctions) features are visible. From the dispersion part of the AC susceptibility, the critical temperatures of the grains T cg as well as the critical temperatures of the Josephson junctions (weak links) T cJ [12] have been obtained. The critical temperatures of the grains T cg were defined as the temperatures in which the diamagnetic signal appears (see inset of Fig. 5). The critical temperatures of the Josephson junctions (weak links) T cJ were taken as the temperatures of the crossing of the zero-level diamagnetic signal and the line fitted to the dispersion part of the AC susceptibility near the superconducting transition (see Fig. 5). These critical temperatures are as follows: T cg = 106.4 K, T cJ = 104.1 K for the bulk (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y and T cg = 107.3 K, T cJ = 103.9 K for the bulk (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y , T cg = 106.5 K, T cJ = 100.2 K for the (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y film and T cg = 106.1 K and T cJ = 97 K for the (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y film, respectively. The critical temperatures of the grains for the superconducting films are comparable with those of bulk samples while the critical temperatures of the Josephson junctions are a few degrees smaller.

For all the samples, the temperature dependence of the dispersion parts of the AC susceptibility does not depend on the AC magnetic field amplitude in the vicinity of the grain critical temperature. The AC susceptibility curves diverge from the zero signal at the temperature about 103.3 and 102.8 K for (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y and for (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y bulk samples, respectively, and about 99.3 and 97.2 K for (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y and for (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y films, respectively. The absorption part of the AC susceptibility exhibits two peaks for the bulk samples concerning to the energy losses connected with the magnetic field penetration into the intra and inter-granular regions (Figs. 1b and 2b) and only one peak for the films which is related to the energy losses in the inter-granular regions (Figs. 3b and 4b). The absorption peaks move to the lower temperatures when the amplitude of the applied magnetic field increases.

The temperature dependencies of the absorption part of AC susceptibility at different magnetic field H AC amplitudes were measured to obtain the critical current density values of the samples. They were derived from the peak position of the absorption part of the susceptibility within the Bean critical state model using the formula [13, 14]:

where H AC is the AC magnetic field amplitude and d is the sample thickness in the direction perpendicular to the AC field. The results of inter-grain critical current density calculations for the bulk and the thin film samples are presented in Fig. 6. The critical current flows through the inter-grain links which may be treated as the Josephson junctions (weak links). The critical current is limited by the weakest junctions on the percolation path of the current. According to the Ginzburg-Landau strong coupling limit approach, the critical current varies with temperature as shown in the following equation [15]:

where T cJ is the critical temperature and J c0 is the critical current at 0 K. Originally, the exponent n was determined to be 1.5 [16, 17] but it may vary within a wide range [18]. If the exponent n is greater than unity, there is strong pinning and a vortex glass structure exists. In this case, the function expressed by (2) has an upward curvature which is typical for HTS. If the exponent n is less than unity, the pinning force is weak and limits the critical current. Then, the function expressed by (2) has a downward curvature, typical for low-temperature superconductors.

The temperature dependencies of the critical current densities of all the samples were fitted using (2) with the two fit parameters: J c0 and n. The values of T cJ, were taken from the experiment. Fits of (2) to the experimental data are shown in Fig. 6 (solid lines) and the values of fit parameters are collected in Table 1.

The highest value of critical currents in the liquid nitrogen temperature J c = 0.39 kAcm −2 (77 K) among all the investigated samples has (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y film, although it is significantly smaller in comparison with the critical currents for YBa 2Cu 3 O x films on silver substrates J c = 2.1 kAcm −2 (77 K) [19, 20], thallium-based (Tl 0.5Pb 0.5)(Sr 0.85Ba 0.15)2Ca 2Cu 3 O x film on silver substrate J c = 11.4 kAcm −2 (77 K) [4] and bismuth 1G superconducting tape J c = 17.5 kAcm −2 (77 K) [21]. All the samples have values of exponent n higher than unity and they are linked to the strong pinning force. The highest value of the exponent n = 2.42 ±0.22 was found for the (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y film.

4 Summary

The (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y and (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y films were obtained directly on silver substrates using the sedimentation process. The thickness of the films (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y and (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y is 195 and 137 μm and the intra- and inter-grain critical temperatures are 106.5 and 106.1, and 100.2 and 97 K, respectively. The critical currents were obtained from the absorption part of the AC susceptibility within the Bean critical state model. The highest value of the critical current J c (77 K) = 386 Acm −2 was found for the (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y film. The critical currents at the liquid nitrogen temperature J c (77 K) of (Bi 0.8Pb 0.2)2Sr 2Ca 2Cu 3 O y and (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y bulk and film samples are considerably smaller than the critical currents for the YBa 2Cu 3 O x films on silver substrates [19, 20] and bismuth 1G superconducting tape [21]. All the samples have the value of the exponent greater than unity, which suggest a strong pinning forces. The highest value of the exponent n = 2.42 ± 0.22 was found for the (Bi 0.6Pb 0.4)2Sr 2Ca 2Cu 3 O y film.

References

Wen, X., Qu, D., Tent, B.A., Shi, D., Tomsic, M., Cowey, L., White, M.: IEEE Trans. Applied Supercond. 9, 1506 (1999)

Liu, D., Zhou, M., Wang, X., Suo, H., Zuo, T., Schindl, M., Flukiger, R.: Supercond. Sci. Technol. 14, 806 (2001)

Deinhofer, C., Gritzner, G.: Supercond. Sci. Technol. 17, 1196 (2004)

Woch, W.M., Tokarz, W., Zalecki, R., Kołodziejczyk, A., Deinhofer, C., Gritzner, G.: Supercond. Sci. Technol. 23, 025004 (2010)

Malozemoff, A.P.: IEEE Spectrum. 30, 26 (1993)

Ullmann, B., Gabler, A., Quilitz, M., Goldacker, W.: IEEE Trans. Applied Supercond. 7, 2042 (1997)

Ma, Y., Watanabe, K., Awaji, S., Motokawa, M.: Physica C 337, 357–360 (2001)

Woch, W.M., Chmist, J., Przewoźnik, J., Niewolski, J., Zalecki, R., Kołodziejczyk A.: Mol. Phys. Reports 34/1, 175 (2001)

Koike, Y., Yamada, Y., Hirabayashi, I., Akata, H., Higashiyama, K: In: Koshizuka N. et al. (eds.) Advances in Superconductivity XI, vol. 741. Springer, Tokyo (1999)

Zang, C., Kulpa, A., Chaklader A.C.D.: Physica C 252, 67 (1995)

Rietveld, H.M.: J. Appl. Crystallogr. 2, 65 (1969)

Woch, W.M., Zalecki, R., Kołodziejczyk, A., Sudra, H., Gritzner, G.: Mater. Sci. (Poland) 26, 1091 (2008)

Bean, C.P.: Phys. Rev. Lett. 8, 250 (1962)

Clem, J.R.: Physica C 50, 153–155 (1988)

Clem, J.R., Bumble, B., Raider, S.I., Gallagher, W.J., Shih, Y.C.: Phys. Rev. B 35, 6637 (1987)

Müller, K.A., Takashige, M., Bednorz, J.: Phys. Rev. Lett. 58, 1143 (1987)

Yeshurun, Y., Malozemoff, A.P.: Phys. Rev. Lett. 60, 2202 (1988)

Woch, W.M., Zalecki, R., Kołodziejczyk, A., Sudra, H., Gritzner, G.: Supercond. Sci. Technol. 21, 085002 (2008)

Zalecki, R., Woch, W.M., Chrobak, M., Kołodziejczyk A.: Acta Phys. Pol. A 121, 850 (2012)

Zalecki, R., Woch, W.M., Chrobak, M., Kołodziejczyk, A.: Acta Phys. Pol. A 126, A-13 (2014)

Woch, W.M., Zalecki, R., Chrobak, M., Kołodziejczyk, A.: Acta Phys. Pol. A 127, 315 (2015)

Acknowledgments

This work was supported by the Polish Ministry of Science and Higher Education and its grants for Scientific Research.

The authors would like to thank prof. Cz. Kapusta for useful comments on the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kowalik, M., Zalecki, R., Woch, W.M. et al. Critical Currents of (Bi1−x Pb x )2Sr2Ca2Cu3O y (x = 0.2 and 0.4) Films Deposited on Silver Substrate by Sedimentation. J Supercond Nov Magn 30, 2387–2391 (2017). https://doi.org/10.1007/s10948-017-4047-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-017-4047-z