Abstract

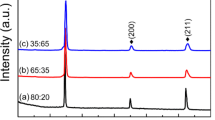

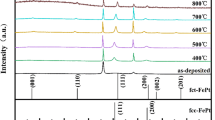

The fully amorphous Fe nanoparticles with controllable size ranging from 80 to 120 nm have been fabricated by direct reduction reactions of Fe2+ ions with NaBH4 as reducing agent. The morphologies and surface structures of these amorphous samples can be modified by varying the addition rate of NaBH4 solution during the reaction process. The uniform nanosized amorphous Fe particles with an average size of about 90 nm can be obtained at suitable reaction addition. The B element is observed to accumulate in the surface of the amorphous samples, which promotes their good thermal and air stability. The surface B concentration can be decreased with increasing the NaBH4 addition rate. Slight surface oxidation varying from FeO to Fe3O4 in the amorphous samples may lead to their different saturation magnetization of 126–140 A ⋅ m2/kg. This simple method, good stability, and high saturation magnetization for these nanosized amorphous Fe particles promise their potential applications in high-frequency and high-temperature soft magnetic devices.

Similar content being viewed by others

References

Sun, S.H., Murray, C.B., Weller, D., Folks, L., Moser, A.: Science 287, 1989 (2000)

Huber, D.L.: Small 1, 482 (2005)

Cheng, X.F., Wu, B.S., Yang, Y., Xiang, H.W., Li, Y.W.: J. Mol. Catal. A: Chem. 329, 103 (2010)

Zeng, Q., Baker, I., Loudis, J.A., Liao, Y., Hoopes, P.J., Weaver, J.B.: Appl. Phys. Lett. 90, 233112 (2007)

Suryanarayana, C., Inoue, A.: Int. Mater. Rev. 58, 131 (2013)

González, J.M., Pérez Alcázar, G.A., Zamora, L.E., Tabares, J.A., Bohórquez, A., Gancedo, J.R.: J. Magn. Magn. Mater. 261, 337 (2003)

Kong, F.L., Chang, C.T., Inoue, A., Shalaan, E., Al-Marzouki, F.: J. Alloy. Compd. 615, 163 (2014)

Stoesser, A., Ghafari, M., Kilmametov, A., Gleiter, H., Sakurai, Y., Itou, M., Kohara, S., Hahn, H., Kamali, S.: J. Appl. Phys. 116, 134305 (2014)

Peng, S., Wang, C., Xie, J., Sun, S.H.: J. Am. Chem. Soc. 128, 10676 (2006)

Cheng, X.F., Wu, B.S., Yang, Y., Li, Y.W.: Catal. Commun. 12, 431 (2011)

Lu, L.R., Ai, Z.H., Li, J.P., Zheng, Z., Li, Q., Zhang, L.Z.: Cryst. Growth Des. 7, 459 (2007)

Ni, X.M., Su, X.B., Zheng, H.G., Zhang, D.G., Yang, D.H., Zhao, Q.B.: J. Cryst. Growth 275, 548 (2005)

Joseyphus, R.J., Shinoda, K., Kodama, D., Jeyadevan, B.: Mater. Chem. Phy. 123, 487 (2010)

Nunes, E.S., Viali, W.R., Silva, S.W., Coaquira, J.A.H., Garg, V.K., Oliveira, A.C., Morais, P.C., Júnior, M.J.: Appl. Surf. Sci. 315, 337 (2014)

Wang, W., Jin, Z.H., Li, T.L., Zhang, H., Gao, S.: Chemosphere 65, 1396 (2006)

Wang, Q.L., Kanel, S.R., Park, H., Ryu, A., Choi, H.: J. Nanopart. Res. 11, 749 (2009)

Zeng, Q., Baker, I., Loudis, J.A., Liao, Y.F., Hoopes, P.J.: Proc. SPIE 6440, 64400H (2007)

Li, X.Q., Zhang, W.X.: Langmuir 22, 4638 (2006)

Crisan, O., von Haeften, K., Ellis, A.M., Binns, C.: J. Nanopart. Res. 10, 193 (2008)

Yang, B., Cao, Y., Zhang, L., Li, R.F., Yang, X.Y., Yu, R.H.: J. Alloy. Compd. 615, 322 (2014)

Cao, Y., Yang, B., Yang, X.Y., Zhang, L., Li, R.F., Yu, R.H.: J. Supercond. Nov. Magn. (2015). doi:10.1007/s10948-013-2132-5

Liaw, B.J., Chiang, S.J., Tsai, C.H., Chen, Y.Z.: Appl. Catal. A: Gen. 284, 239 (2005)

Grinstaff, M.W., Salamon, M.B., Suslick, K.S.: Phy. Rev. B 48, 269 (1993)

Park, J.W., Chae, E.H., Kim, S.H., Lee, J.H., Kim, J.W., Yoon, S.M., Choi, J.Y.: Mater. Chem. Phy. 97, 371 (2006)

Wu, Z.G., Munoz, M., Montero, O.: Adv. Powder Technol. 21, 165 (2010)

Yamashita, T., Hayes, P.: Appl. Surf. Sci. 254, 2441 (2008)

Gota, S, Guiot, E, Henriot, M., Gautier-Soyer, M.: Phys. Rev. B 60, 14387 (1999)

Acknowledgments

This work was supported by Beijing Natural Science Foundation under Grant No. 2132039, the National Nature Science Foundation of China under Grant No. 51101007, and the National Basic Research Program of China (973 Program) under Grant No. 2010CB934602.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, B., Yang, X.Y., Li, X.P. et al. Surface Modification and Enhanced Performance of Chemically Synthesized Nanosized Amorphous Fe Particles. J Supercond Nov Magn 28, 2177–2182 (2015). https://doi.org/10.1007/s10948-015-3021-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-015-3021-x