Abstract

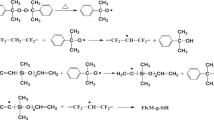

Foamed silicone rubber was prepared by mixing 45% vinyl silicone oil (Base), Karstedt platinum catalyst (Cata), and hydrogenated silicone oil (SiH) and the resulting material was subjected to secondary vulcanization, which led to its performance requirements. Vinyl silicone oil and hydrogenated silicone oil underwent an addition reaction under the action of a platinum catalyst to form an elastomer with a cross-linked network structure. The results showed that by increasing the content of hydrogenated silicone oil in the formulation, the elongation at break of the foamed silicone gel material decreased but the tensile strength increased. When the content of hydrogenated silicone oil in the formulation decreased, the elongation at break of the foamed silicone material increased. When the content of Karstedt catalyst in the formulation increased, the formation time of the reaction gel was greatly shortened, and the cell structure tended to be dense but delicate. When the proportion of vinyl silicone oil in the formulation increased, the elongation at break of the foamed, molded silicone rubber increased. However, the elastic modulus decreased, and the thermal stability improved. Finally, a more suitable formulation of VBase:VCata:VSiH = 32:1:2 was obtained, which showed a tear resistance of 5.52 KN/m, ductility of 133%, and limiting oxygen index of 26 with a stability temperature of 346.8 °C when the thermal mass loss reached 95%.

Similar content being viewed by others

References

Q. Zhang, J.G. Deng, L.X. Ji et al., Preparation and properties of liquid silicone rubber microporous materials. Silicone Mater. 5, 277–280 (2008)

Liu, K., Gong, S.K., Chen, B., et al.: Composition analysis of an aviation rubber sealing material. Chem. Anal. Metrol. (2010).

X.L. Ding, Z.Z. Zhen, Clinical application of foam silicone rubber ball modification of movable eye seat. J. Pract. Med. 7, 491–4929 (1996)

Y.M. Zhang, K. Wang, D.L. Fan, Research progress on biocompatibility modification of medical silicone rubber. Chongqing Med. J. 35(3), 274–276 (2006)

S.P. Li, B. Li, Application of foamed silicone rubber on battery housing sealing ring. Auto Parts 119(5), 86–88 (2018)

W.W. Chen, W.L. Liao, B. Luo et al., Preparation and performance test of new food-grade room-temperature vulcanized silicone rubber. J. Zhong kai College Agri. Eng. 33(4), 36–39 (2020)

G. Li, Preparation and Properties of High Temperature Vulcanized Silicone Rubber Foam (Qing dao University of Science and Technology, Qingdao, 2016)

G. Chen, M.T. Sun, H.A. Chen, Preparation process of hot air vulcanized silicone rubber sponge. Silicone Mater. 5, 5–7 (1997)

Shi, Y.G., Lei W.H., Zhang, C.S., et al.: Preparation technology and properties of hot silicon sulfide foam. Proceedings of the 2006 National Symposium on Polymer Materials Science and Engineering (2006).

Q. Zhao, W.H. Lei, Z.Y. Gu et al., Structure and properties of silicone rubber/EPDM foam alloy materials. Rubber Ind. 48(5), 277–281 (2001)

J.H. Liang, Preparation and Properties of RTV-2 Liquid Foamed Silicone Rubber with Additive Molding (South China University of Technology, Guangzhou, 2018)

Liu, D.L., Liu, P.B., Xu, W.: Preparation and mechanical properties of open-cell foam silicone rubber materials. Plastics Industry, 98–99 (2006).

F. Bruce, Organosilicon elastomer. Rubber World 205(5), 16–18 (1992)

Y. Li, G.C. Zhang, H.C. Li et al., Preparation and properties of silicone foam materials. Aerosp. Mater. Technol. 36(3), 4–9 (2006)

Bauman, T.M., Therese, M., Dietlein, J.E., et al.: Water-blown silicone foam: US, 4599367 (1986)

Yaginuma, A., Silicone rubber sponge composition and silicone rubber sponge obtained therefrom: US, US6387971 B1 (2002)

Yoshida, T., Takahashi, M.: Foamable silicone rubber composition: US5019295 (A) (1991)

B.L. Lv, D.X. Liu, Practical Rubber Manual (Chemical Industry Press, Beijing, 2010)

C.W. Nemeth, Overview of silicone foam chemistry and product performance. J. Appl. Polym. Sci. 72(6), 145–167 (1980)

Y. Hu, G.P. Yao, Preparation of ductile foam silicone rubber with physical foaming agent. Silicone Mater. 14(1), 11–14 (2000)

G.P. Yao, Y. Hu, Compression chemical stress relaxation of ductile silicone rubber foam rubber. Polym. Mater. Sci. Eng. 6, 68–71 (1998)

Y. Xin, Y.Z. Ma, W. Yao, A new method for preparing open-cell silicone rubber foam. Spec. Rubber Prod. 2(3), 32–33 (2001)

S. Susumu, G.Y. Wang, Liquid silicone rubber woven with open hole structure. World Rubber Ind. 31(11), 13–16 (2004)

Smith, R.L.: Room temperature vulcanizing silicone rubber foam: US, US3516951(A) (1970).

D.Z. Chen, S.P. Yi, P.F. Fang et al., Synthesis and characterization of novel room temperature valcunized (RTV) silicone rubber using octal [(trimethyoxysily) ethyl] poss as crosslinker. React. Funct. Polym. 71, 502–511 (2011)

D.Z. Chen, S.P. Yi, W.B. Wu et al., Synthesis and of novel room temperature vulcanized (RTV) silicone rubber using vinyl-poss derivatives as cross linking agent. Polymer 51, 3867–3878 (2010)

D.Z. Chen, Y. Liu, C. Huang, Synergistic effect between POSS and fumed silicone on thermal stabilities and mechanical properties of room temperature vulcanized (RTV) silicone rubbers. Polym. Degrad. Stab. 97, 308–315 (2012)

H.J. You, C.D. Han, Development of a mathematical model of foam devolatilization. Polym. Proc. Eng. 2, 129 (1984)

M. Amon, C.D. Denson, A study of the dynamics of foam growth: analysis of the growth of closely spaced spherical bubbles. Polym. Eng. Sci. 24(13), 1026–1034 (1984)

C.L. Sun, W.E.I. Gang, Research progress of silicone rubber foam materials in China. Elastomer 19(5), 55–58 (2009)

K.Z. Wang, Development and application of plastic additives. Plastics Sci. Technol. 117(1), 45–54 (1997)

Acknowledgements

National Natural Science Foundation of China (22271025, 22301022), a Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions, Postgraduate Research & Practice Innovation Program Project of Jiangsu Province (No. KYCX2_3050) supported this work and all the above support is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Jingjing Yang and Zhichen Zhu were synthesized the formed silicone rubber and characterized the properties. Wenyan Huang was designed the synthesitical method and instructed the experiment. Wenyan Huang and Jingjing Yang were writing the paper. Xiang Jin gave the instruction of the experiment. Lijiang,Hongjun Yang, Qimin Jiang, Xiaoqiang Xue and Bibiao Jiang were reviewed the paper and modified the manuscript

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, J., Zhu, Z., Jiang, L. et al. A facile method for the synthesis of foamed silicone rubber. J Porous Mater 31, 1143–1153 (2024). https://doi.org/10.1007/s10934-024-01605-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-024-01605-9