Abstract

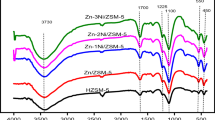

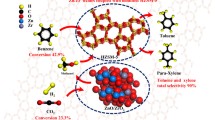

In this report, a catalytic enhanced-conventional process production background was employed to determine the most cost-effective and environmentally friendly techniques to improve the catalytic production of toluene and other aromatic compounds from propane aromatization. 2 wt% of zinc was co-impregnated with 1–3 wt% of cobalt on HZSM-5. Characterizations and analysis showed that catalysts are crystalline and microporous. Propane conversion was carried out at 540 °C, 1200 ml/g-h gas hourly space velocity and atmospheric pressure over Zn–Co/ZSM-5 bimetallic catalysts. Toluene selectivity in the aromatic products was greatly improved and sustained significantly together with other aromatic products. Catalytic conversion of propane and aromatic yield over Zn–Co/ZSM-5 was improved and stabilized due to metallic collaboration on HZSM-5. Aromatic yield averaged 46, 32, and 36%, respectively, for 1–3 wt% Co in Zn–Co/ZSM-5 bimetallic catalyst. Average toluene selectivity in the aromatic products for 12 h time on stream from 60, 50 and 51% for 1–3 wt% Co loading. The threshold loading of cobalt with zinc was 2% above which the general aromatic selectivity declined. A decrease in conversion from 73 to 15% was observed for flowrate increase from 6 to 35 ml min−1 and an increase in aromatic selectivity from 80 to 87%. An increase in temperature of 500–560 °C increased catalytic performance, 32–47% for propane conversion, and 79–86% aromatic selectivity.

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in this published article and are provided in the supplementary information files.

Abbreviations

- BET:

-

Brunauer–Emmett–Teller

- BTEX:

-

Benzene toluene ethylbenzene xylene

- FTIR:

-

Fourier transform infra-red

- H2-TPR:

-

Hydrogen-temperature programming reduction

- SEM:

-

Scanning slmctron microscopy

- TEM:

-

Transmission electron microscopy

- XPS:

-

X-ray photoelectron spectroscopy

- XRD:

-

X-ray diffraction

- XRF:

-

X-ray fluorescence

References

B. Liu, S. Lu, E. Liu, X. Hu, J. Fan, Korean J. Chem. Eng. 35(4), 867–874 (2018)

B.S. Kwak, W.M. Sachtler, Korean J. Chem. Eng. 13(4), 356–363 (1996)

Y.K. Park, D.H. Kim, S.I. Woo, Korean J. Chem. Eng. 14(4), 249–256

X. Chen, M. Dong, X. Niu. K. Wang, G. Chen, W. Fan, Z. Qin, Chin. J. Catal. 36(6), 880–888 (2015)

J. Park, W.Y. Lee, H.S. Hahm, Korean J. Chem. Eng. 19(3), 411–416 (2002)

T. Yang, L. Cheng, N. Li, D. Liu, Ind. Eng. Chem. Res. 56(41), 11763–11772 (2017)

D. Bhattacharya, S. Sivasanker, J. Catal. 153(2), 353–355 (1995)

Y. Xu, L. Liwu, Appl. Catal. A 188(1–2), 53–67 (1999)

I.D. Mall, Petrochemical Process Technology, 1st edn. (New Delhi, Macmillan India, 2007)

K. Frey, L.M. Lubango, M.S. Scurrell, L. Guczi, Reaction Kinetics, Mechanisms and Catalysis 104(2), 303–309 (2011)

C. Song, K. Liu, D. Zhang, S. Liu, X. Li, S. Xie, L. Xu, Appl. Catal. A 470, 15–23 (2014)

M. Miyamoto, K. Mabuchi, J. Kamada, Y. Hirota, Y. Oumi, N. Nishiyama, S. Uemiya, J. Porous Mater. 22(3), 769–778 (2015)

M.S. Pereira, M.S. Alexander, A. Marco, N. Chaer, J. Phys. Chem. C 115(20), 10104–10113 (2011)

S.M. Csicsery, Shape-selective Catalyst in Zeolite. Zeolite, Vol. 4, Issue 3, 202–213. 1984

H. Jiang, M.S. Tzou, W.M.H. Sachtler, Appl. Catal. 39, 255–265 (1988)

M. Guisnet, N.S. Gnep, D. Aittaleb, Y.J. Doyemet, Appl. Catal. A 87(2), 255–270 (1992)

N. Viswanadham, G. Muralidhar, T.S.R.P. Rao, J. Mol. Catal. A 223, 269–274 (2004)

S. Phatanasri, P. Praserthdam, A. Sripusitto, Korean J. Chem. Eng. 17(4), 409–413 (2000)

B. Xu, M. Tan, X. Wu, H. Geng, S. Zhao, J. Yao, et al., Propane aromatization tuned by tailoring Cr Modified Ga/ZSM-5 catalysts. ChemCatChem 13(16), 3601–3610 (2021)

H. Fan, X. Nie, C. Song, X. Guo, Mechanistic Insight into the Promotional Effect of CO2 on Propane Aromatization over Zn/ZSM-5 (Industrial & Engineering Chemistry Research, 2022)

T. Pan, S. Ge, M. Yu, Y. Ju, R. Zhang, P. Wu, … Z. Wu, Synthesis and consequence of Zn modified ZSM-5 zeolite supported Ni catalyst for catalytic aromatization of olefin/paraffin. Fuel 311, 122629 (2022)

C.W. Chang, J.T. Miller, Catalytic process development strategies for conversion of propane to liquid hydrocarbons. Appl. Catal. A 643, 118753 (2022)

S. Song, T. Li, Y. Ju, Y. Li, Z. Lv, P. Zheng, et al., Lanthanum/gallium-modified Zn/ZSM-5 zeolite for efficient isomerization/aromatization of FCC light gasoline. Ind. Eng. Chem. Res. 61(27), 9667–9677 (2022)

S. Hajimirzaee, S. Mehr, A., & E. Kianfar (2020). Modified ZSM-5 zeolite for conversion of LPG to aromatics. Polycyclic Arom. Compd. 1–14

I.B. Dauda, M. Yusuf, S. Gbadamasi, M. Bello, A.Y. Atta, B.O. Aderemi, B.Y. Jibril, ACS Omega (2020)

G.G. Oseke, A.Y. Atta, M. Bello, J.B. Yakubu, B.O. Aderemi, Appl. Petrochem. Res. 10(2), 55–65 (2020)

G.G. Oseke, A.Y. Atta, M. Bello, J.B. Yakubu, B.O. Aderemi. J. King Saud Univ. Eng. Sci. 33, 531–538 (2021)

G.G. Oseke, A.Y. Atta, M. Bello, J.B. Yakubu, B.O. Aderemi, NSChE J. 35(1), 17 (2020)

G.G. Oseke, A.Y. Atta, M. Bello, J.B. Yakubu, B.O. Aderemi. J. Porous Mater. https://doi.org/10.1007/s10934-022-01294-2 (2022)

J. Liu, G. Jiang, Y. Liu, J. Di, Y. Wang, Z. Zhao, J. Liu, Sci. Rep. 4, 7276 (2014)

R. Sabarish, G. Unnikrishnan, SN Appl. Sci. 1(9), 989 (2019)

B. Liu, S. Lu, E. Liu, X. Hu, Fan, J. Korean J. Chem. Eng. 35(4), 867–874 (2018)

J. Park, W.Y. Lee, H.S. Hahm, Korean J. Chem. Eng. 19(3), 411–416 (2000)

Y. Jia, J. Wang, K. Zhang, W. Feng, S. Liu, C. Ding, P. Liu, Microporous Mesoporous Mater. 247, 103–115 (2017)

V. Ramasubramanian, D.J. Lienhard, H.G.L. Ramsurn, G.L. Price, Catal. Lett. 149(4), 950–964 (2019)

W. Zhou, J. Liu, J. Wang, L. Lin, X. Zhang, N. He, H. Guo, Catal. Lett. 149(8), 2064–2077 (2019)

Y. Xin, P. Qi, X. Duan, H. Lin, Y. Yuan, Catal. Lett. 143(8), 798–806 (2013)

B.K. Van der, V.V. Galvita, G.B. Marin, Appl. Catal. A 492, 117–126 (2015)

W. Wannapakdee, D. Suttipat, P. Dugkhuntod, T. Yutthalekha, A. Thivasasith, P. Kidkhunthod, C. Wattanakit, Fuel 236, 1243–1253 (2019)

S.H. Zhang, Z.X. Gao, S.J. Qing, S.Y. Liu, Y. Qiao, Chem. Pap. 68(9), 1187–1193 (2014)

X. Niu, J. Gao, Q. Miao, M. Dong, M.G. Wang, W. Fan, J. Wang, Microporous Mesoporous Mater. 197, 252–261 (2014)

X. Wang, J. Zhang, T. Zhang, H. Xiao, F. Song, Y. Han, Y. Tan, RSC Adv. 6(28), 23428–23437 (2016)

E. Mannei, F. Ayari, E. Asedegbega-Nieto, M. Mhamdi, G. Delahay, Z. Ksibi, A. Ghorbel, Chem. Pap. 73(3), 619–633 (2019)

A.K. Mageed, A.D. Radiah, A. Salmiaton, S. Izhar, M.A. Razak, J. King Saud Univ. Sci. 31(4), 878–885 (2019)

W.W. Fang, M.M. Mu, J. Tian, L.G. Chen, Y. Li, Chem. Pap. 70(4), 430–435 (2016)

T.K.T. Dao, C.L. Luu, Nanosci. Nanatechnol. 6(3), 035014 (2015)

Y.C. Yang, H.S. Weng, J. Mol. Catal. A 304(1–2), 65–70 (2009)

J. Jarvis, P. He, A. Wang, H. Song, Fuel 236, 1301–1310 (2019)

J. Jarvis, A. Wong, P. He, Q. Li, H. Song, Fuel 223, 211–221 (2018)

M. Roy, G. Sourav, K.N. Milan, Mater. Chem. Phys. 159, 101–106 (2015)

S.H. Zhang, Z.X. Gao, S.J. Qing, S.Y. Liu, Y. Qiao, Chem. Pap. 68(9), 1187–1193

M.S. Scurrell, Appl. Catal. 41, 89–98 (1988)

T.E. Tshabalala, M.S. Scurrell, Catal Commun. 72, 49–52 (2015)

Y. Xu, S. Yoshizo, Z. Zhan-Guo, Appl. Catal. A 452, 105 (2013)

X. Zhu, H. Wang, G. Wang, Y. Hou, J. Zhang, C. Li, C. Yang, J. Porous Mater. 28(4), 1059–1067 (2021)

E.E. Peter, A.Y. Atta, B. Mukhtar, B.O. Aderemi, B.J. El-Yakub, J. King Saud Univ. Eng. Sci. 33(7), 447–458 (2021)

Acknowledgements

A deep appreciation from the authors goes to the Petroleum Technology Development Fund (PTDF), Abuja, Nigeria for providing support and funding for this research.

Funding

This research was funded by Petroleum Technology Development Fund, PTDF, Ministry of Petroleum Resources, Abuja-Nigeria.

Author information

Authors and Affiliations

Contributions

All authors were involved in the manuscript proofreading but below are the unique contributions of an individual with the corresponding author, Dr. Oseke Godwin Gbenga carried out the research in the laboratory and prepared the manuscript. Professor AAY was deeply involved in catalyst synthesis and effective operations of the fixed bed reactor. Professor MB and Professor EYBJ contributed to catalyst performance tests in relation to characterization. Professor ABO contributed to catalyst characterization, understanding the reaction mechanism in relation to performance tests, and general organization of the research. EEP contributed to understanding the reaction mechanism, temperature effect on product distribution, and metal catalyst interactions.

Corresponding author

Ethics declarations

Conflict of interest

The authors of this paper declare that we have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Oseke, G.G., Peter, E.E., Atta, A.Y. et al. Improved aromatic yield and toluene selectivity in propane aromatization over Zn–Co/ZSM-5: effect of metal composition and process conditions. J Porous Mater 30, 999–1010 (2023). https://doi.org/10.1007/s10934-022-01397-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-022-01397-w