Abstract

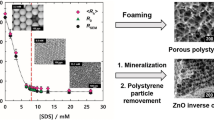

Here we fabricated porous polystyrene (PS) plates via a two-step process: swelling process and freezing process. An aqueous solution containing tetrahydrofuran (THF) was used in the swelling process and liquid nitrogen for the freezing process. Two types of the structures as sponge structure and pore structure were found by adjusting THF content in the solution, swelling time and freezing time, respectively. The pore size was mainly in the range of 1–4 μm with narrow size distribution. The surface hydrophilicity changed slightly with THF content and the swelling time. However, the absorption properties of PS plates in either water or oil increased with THF content in the solution from 70 to 80 wt%, the swelling time from 5 to 10 min, and the freezing time from 1 to 1.5 h.

Similar content being viewed by others

References

M.S. Park, J.K. Kim, Breath figure patterns prepared by spin coating in a dry environment. Langmuir 20, 5347–5352 (2004)

K.H. Wong, M. Hernandez-Guerrero, A.M. Granville, T.P. Davis, C. Barner-Kowollik, M.H. Stenzel, Water-assisted formation of honeycomb structured porous films. J. Porous Mater. 13, 213–223 (2006)

M.M. Tao, F. Liu, L.X. Xue, Poly(vinylidene fluoride) membranes by an ultrasound assisted phase inversion method. Ultrason. Sonochem. 20, 232–238 (2013)

T.-I. Yang, T.-L. Su, P.-L. Lin, I.-H. Tseng, C.-H. Chang, H.-W. Fang, Fabrication of porous polylactic acid films assisted by dip-coating and template leaching techniques. J. Appl. Polym. Sci. 124(3), 2333–2339 (2012)

J. Peng, Y. Han, Y. Yang, B. Li, The influencing factors on the macroporous formation in polymer films by water droplet templating. Polymer 45, 447–452 (2004)

J.H. Bang, K.S. Suslick, Applications of ultrasound to the synthesis of nanostructured materials. Adv. Mater. 22, 1039–1059 (2010)

M. Srinivasarao, D. Collings, A. Philips, S. Patel, Three-dimensionally ordered array of air bubbles in a polymer film. Science 292(6), 79–83 (2010)

H. Liua, K. Nakagawab, D. Chaudharya, Y. Asakumac, M.O. Tadé, Freeze-dried macroporous foam prepared from chitosan/xanthan gum/montmorillonite nanocomposites. Chem. Eng. Res. Des. 8(9), 2356–2364 (2011)

R. Okaji, S. Sakashita, K. Tazumi, K. Taki, S. Nagamine, M. Ohshima, Interconnected pores on the walls of a polymeric honeycomb monolith structure created by the unidirectional freezing of a binary polymer solution. J. Mater. Sci. 48, 2038–2045 (2013)

M. Shibuya, J.F. Despres, Gradient microstructure of titanium nitride fabricated by combustion synthesis with liquid nitrogen. J. Eur. Ceram. Soc. 25(16), 3657–3662 (2005)

S.H. Im, U. Jeong, Y. Xia, Polymer hollow particles with controllable holes in their surfaces. Nat. Mater. 4(9), 671–675 (2005)

S.H. Im, O.O. Park, Fabrication of polymeric hollow spheres having macropores by a quenching and sublimation process. Macromol. Res. 11, 518–522 (2003)

J.-W. Kim, K. Tazumi, R. Okaji, M. Ohshima, Honeycomb monolith-structured silica with highly ordered, three-dimensionally interconnected macroporous walls. Chem. Mater. Commun. 21, 3476–3478 (2009)

V.M. Gun’ko, R. Leboda, J. Skubiszewska-Zieba, B. Gawdzik, B. Charmas, Structural characteristics of porous polymers treated by freezing with water or acetone. Appl. Surf. Sci. 252, 612–618 (2005)

N. Tang, J. Liu, J. Ma, Present situation and development of membrane materials for membrane distillation. Chem. Ind. Eng. Prog. 22(8), 808–812 (2003)

P.T.C.M. Tanev, T.J. Pinnavaia, Nature 368, 321–323 (1994)

X. Wang, W. Li, V. Kumar, A method for solvent-free fabrication of porous polymer using solid-state foaming and ultrasound for tissue engineering applications. Biomaterials 27, 1924–1929 (2006)

H. Yabu, M. Shimomura, Simple fabrication of microlens arrays. Langmuir 21, 1709–1711 (2005)

J.-K. Kim, K. Taki, M. Ohshima, Preparation of a unique microporous structure via two step phase separation in the course of drying a ternary polymer solution. Langmuir 23, 12397–12405 (2007)

H. Zhang, A.I. Cooper, Aligned porous structures by directional freezing. Adv. Mater. 19, 1529–1533 (2007)

L.-S. Wan, B.-B. Ke, J. Zhang, Z.-K. Xu, Pore shape of honeycomb-patterned films: modulation and interfacial behavior. J. Phys. Chem. B 116, 40–47 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, S., Li, G., Zhang, J. et al. Structuring of polystyrene surface via swelling–freezing drying in a binary solvent solution. J Porous Mater 22, 859–865 (2015). https://doi.org/10.1007/s10934-015-9959-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-015-9959-z