Abstract

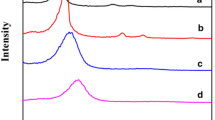

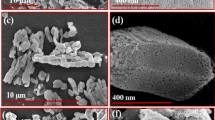

Mesoporous Santa Barbara Amorphous-15 is known to possess a small fraction of micropores, in the walls of mesopores. The ratio of micropore to mesopore area can have a profound influence on the application of this highly ordered material in various fields. The present work aims to investigate the influence of dicarboxylic acids as organic structure interrupting agents on the micropore to mesopore ratio. The physiochemical characterization of the synthesized samples including electron microscopy, nitrogen adsorption–desorption isotherms, MAS 29Si-NMR, FT-IR demonstrate a distinct change in the morphology and micropore area due to the different dicarboxylic acids used during synthesis. Our results show that the decrease in chain length of the dicarboxylic acid has a direct relation to the increase in micropore area which has a significant role in the adsorption properties of mesoporous silica. Thus the dicarboxylic acid mediated tuning of the micropores area of mesoporous silica can be used for various applications.

Similar content being viewed by others

References

F. Qu, G. Zhu, S. Huang, S. Li, S. Qiu, ChemPhysChem 7, 400 (2006)

C. Charnay, S. Bégu, C. Tourné-Péteilh, L. Nicole, D.A. Lerner, J.M. Devoisselle, Eur. J. Pharm. Biopharm. 57, 533 (2004)

S.W. Song, K. Hidajat, S. Kawi, Langmuir 21, 9568 (2005)

D.H. Hwang, D. Lee, H. Lee, D. Choe, S.H. Lee, K. Lee, Korean J. Chem. Eng. 27, 1087 (2010)

J.M. Rosenholm, M. Lindén, J. Control Release 128, 157 (2008)

L. Li, C. Liu, A. Geng, C. Jiang, Y. Guo, C. Hu, Mater. Res. Bull. 41, 319 (2006)

T. Kimura, K. Kuroda, Adv. Funct. Mater. 19, 511 (2009)

Z. Li, L. Yu, B. Dong, F. Geng, L. Zheng, G. Li, J. Dispers. Sci. Technol. 29, 1066 (2008)

C.Y. Won, S. Andreas, Chem. Mater. 23, 1761 (2011)

E.C.P. Anders, Science 8, 145 (2003)

R. Roger, M. Louis, Chem. Mater. 13, 2999 (2001)

Y. Li, N. Li, J. Tu, X. Li, B. Wang, Y. Chi, D. Liu, D. Yang, Mater. Res. Bull. 46, 2317 (2011)

F. Kleitz, U. Wilczok, F. Schüth, F. Marlow, Phys. Chem. Chem. Phys. 3, 3486 (2001)

Q. Shi, Y. Yan, F. Zhang, S. Xie, B. Tu, D. Zhao, Adv. Funct. Mater. 15, 1377 (2005)

J. Tu, R. Wang, W. Geng, X. Lai, T. Zhang, N. Li, N. Yue, X. Li, Sens. Actuators B 136, 392 (2009)

L. Huang, S. Kawi, K. Hidajat, S.C. Ng, Micropor. Mesopor. Mater. 88, 254 (2006)

Y. Zhang, Z. Zhi, T. Jiang, J. Zhang, Z. Wang, S. Wang, J. Control Release 145, 257 (2010)

P.N. Sajo, S. Igor, Micropor. Mesopor. Mater. 116, 581 (2008)

Z. Wang, S. Zong, J. Yang, J. Li, Y. Cui, Biosens. Bioelectron. 26, 2883 (2011)

G.B. Martín, E.R. Alberto, J.A.A.S. Galo, ACS Appl. Mater. Interfaces 2, 360 (2010)

Y. Zhu, J. Shi, H. Chen, W. Shen, X. Dong, Micropor. Mesopor. Mater. 84, 218 (2005)

Q. Huo, D. Zhao, J. Feng, K. Weston, S.K. Buratto, G.D. Stucky, Adv. Mater. 9, 974 (1997)

J. Wang, C.K. Tsung, R.C. Hayward, Y. Wu, G.D. Stucky, Angew. Chem. Int. Ed. 44, 332 (2005)

D. Zhao, J. Sun, Q. Li, G.D. Stucky, Chem. Mater. 12, 275 (2000)

S.P. Naik, M. Ogura, T. Okubo, Ind. Eng. Chem. Res. 44, 4156 (2005)

Y. Lu, R. Ganguli, C.A. Drewlen, M.T. Anderson, C.J. Brinker, W. Gong, Y. Guo, H. Soyez, B. Dunn, M.H. Huang, J.I. Zink, Nature 389, 364 (1997)

H. Miyata, T. Suzuki, A. Fukuoka, T. Sawada, M. Watanabe, T. Noma, K. Takada, T. Mukaide, K. Kuroda, Nat. Mater. 3, 651 (2004)

S. Schacht, Q. Huo, I.G. VoigtMartin, G.D. Stucky, F. Schüth, Science 273, 768 (1996)

M.C. Chao, D.S. Wang, H.P. Lin, C.Y. Mou, Mater. Chem. 13, 2853 (2003)

C. Yu, B. Tian, J. Fan, G.D. Stucky, D. Zhao, J. Am. Chem. Soc. 124, 4556 (2002)

A. Sayari, Angew. Chem. Int. Ed. 39, 2920 (2000)

D. Yan, X.J. Meng, S.G. Li, F.S. Xiao, Micropor. Mesopor. Mater. 82, 121 (2005)

J.B. Pang, K.Y. Qiu, Y. Wei, J. Non Cryst. Solids 283, 101 (2001)

L. Hong-Ping, M. Chung-Yuan, Acc. Chem. Res. 35, 927 (2002)

M.K. Naskar, M. Eswaramoorthy, J. Chem. Sci. 120, 181 (2008)

C. Cooper, R. Burch, Water Res. 33, 3689 (1999)

D. Zhu, H. Zhang, Q. Tao, Z. Xu, S. Zheng, Environ. Toxicol. Chem. 28, 1400 (2009)

V. Meynen, P. Cool, E.F. Vansant, Micropor. Mesopor. Mater. 125, 170 (2009)

G. Cavallaro, P. Pierro, F.S. Palumbo, F. Testa, L. Pasqua, R. Aiello, Drug Deliv. 11, 41 (2004)

M.K. Arouaa, S.P.P. Leonga, L.Y. Teoa, C.Y. Yin, W.M.A.W. Daud, Bioresour. Technol. 99, 5786 (2008)

B.H. Hameed, A.L. Ahmad, K.N.A. Latiff, Dyes Pigm. 75, 143 (2007)

A.M. Peers, J. Catal. 4, 499 (1965)

Acknowledgments

The authors wish to acknowledge Nano Mission Council, DST and SASTRA University for infrastructural and financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gandhi, S., Sethuraman, S. & Krishnan, U.M. In-situ generation of large microporous skeleton in mesoporous silica framework using different dicarboxylic acids. J Porous Mater 21, 53–62 (2014). https://doi.org/10.1007/s10934-013-9746-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-013-9746-7