Abstract

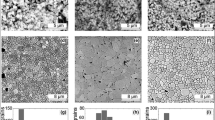

Aiming at ceramic materials of low thermal radiation emittance titania yttrium oxide ceramics have been prepared by sintering in air at 1,100 and 1,400 °C, respectively, and characterised. Due to its high infrared refractive index, average pore sizes up to 1 μm for optimal Mie scattering cross sections and over 35% porosity the material is a promising candidate for elevated temperature insulations. The essentially in large pore growth is achieved by graphitic nano and micro particle additives. The microstructure parameters of porosity, specific surface area, median and average pore sizes are determined by mercury intrusion porosimetry. Beyond this classical technique supplementary measurements by X-ray absorption and X-ray refractometry reveal considerably larger average pore sizes due to closed pores not accessible for mercury. An additional advantage of the X-ray techniques is their non-destructive application, which allows other treatments afterwards. The combined application of both methods provides additional information and reliability in case of complex ceramic microstructures and may serve for improved developments of porous ceramics with optimised thermal scattering for energy savings in high temperature applications.

Similar content being viewed by others

References

U. Schulz, B. Saint-Ramond, O. Lavigne, P. Moretto, A. van Lieshout, A. Börger, Low thermal conductivity ceramics for turbine blade thermal barrier coating application. Ceram. Eng. Sci. Process. 25(4), 375–380 (2004)

O. Rozenbaum, D. De Sousa Meneses, P. Echegut, Texture and porosity effects on the thermal radiative behavior of alumina ceramics. Int. J. Thermophys. 30(2), 580–590 (2002)

J. Manara, M. Reidinger, S. Korder, M. Arduini-Schuster, J. Fricke, Development and characterization of low-emitting ceramics. Int. J. Thermophys. 28(5), 1628–1645 (2007)

Keller, M.H., Manara, J., Tzschichholz, G., Steinborn, G.: Porous ceramics with optimized infrared-optical properties. Conference contribution at Eurotherm, Eindhoven (2008)

H. Salmang, H. Scholze, in Keramik, 7th edn, ed. by R. Telle (Springer, Berlin, 2007), p.174, ISBN 3-540-63273-5

Klobes, P., Meyer, K., Munro, R.G.: Porosity and specific surface area measurements for solid materials. NIST Recommended Practice Guided, Special Publication 960-17, (2006)

Klobes, P., Röhl-Kuhn, B.: Einsatz der Quecksilberporosimetrie zur Grünkörpercharakterisierung—Aussagemöglichkeiten, Grenzen und Perspektiven. DKG-Handbuch d. Technischen Keramischen Werkstoffe. In: Kriegesmann, J. (ed.) Chap. 3.4.1.3, pp.1–14, 71. Ergänzungslieferung, (2002)

K.W. Harbich, P. Klobes, M.P. Hentschel, Microstructural characterization of porous materials by two-dimensional X-ray refraction topography. Colloids Surf. A Physicochem. Eng. Asp. 241(1–3), 225–229 (2004)

N. Mizutani, Y. Tajima, M. Kato, Phase relations in the system TiO2-Y2O3. J. Am. Ceram. Soc. 59(3–4), 168 (1976)

ISO 15901-1:2005, Pore size distribution and porosity of solid materials by mercury porosimetry and gas adsorption—Part 1: Mercury porosimetry

H. Giesche, Mercury porosimetry a general practical overview. Part. Part. Syst. Charact. 23(1), 9–19 (2006)

D. Hoffmann, K. Rübner, Characterization of mineral building materials by mercury porosimetry. Part. Part. Syst. Charact. 23(1), 20–28 (2006)

F.E. Fensch-Kleemann, K.W. Harbich, M.P. Hentschel, Microstructural characterization of porous ceramics by X-ray refraction topography. cfi/Ber. DFG 79(11), E35–E38 (2002)

L. Ratke, P.W. Voorhees, Growth and Coarsening—Ostwald Ripening in Material Processing (Springer, Berlin, Heidelberg, New York, 2002). ISBN 3-540-42563-2

R. Siegel, J.R. Howell, Thermal Radiation-Heat Transfer (McGraw-Hill, Washington, 1981)

Acknowledgments

The precise performance of numerous MIP measurements by A. Zimathies at the Division of Structure and Polymer Analysis is thankfully acknowledged. Many thanks also to B. Strauss at the Division of Surface Technologies for carrying out the SEM-micrographs. This work has benefitted from several discussions with M. H. Keller, M. Arduini-Schuster and J. Manara from the Bavarian Centre for Applied Energy Research (ZAE Bayern), Wuerzburg, Germany. Financial support of the Deutsche Forschungsgemeinschaft (DFG) under contract number STE 1120/3-2 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tzschichholz, G., Steinborn, G., Hentschel, M.P. et al. Characterisation of porous titania yttrium oxide compounds by mercury intrusion porosimetry and X-ray refractometry. J Porous Mater 18, 83–88 (2011). https://doi.org/10.1007/s10934-010-9358-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-010-9358-4