Abstract

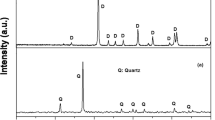

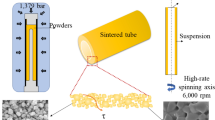

A low cost macroporous support for ceramic membranes was prepared by in situ reaction sintering from local natural mineral kaolin with dolomite as sintering inhibitor. The characterization focused on the phase evolution, microstructure, pore structure, mechanical strength and water permeability at various compositions and sintering temperatures. The sintering of kaolin was improved with 5 wt% dolomite, but clearly inhibited with ≥10 wt% dolomite. For the 20 wt% dolomite samples, the crystalline phases were mainly composed of mullite, cordierite and anorthite after sintering between 1,150 and 1,300 °C. Moreover, both mean pore size and mechanical strength increased with increasing sintering temperature from 1,100 to 1,300 °C, but the water permeability and porosity decreased. The 1,250 °C sintered macroporous support with 20 wt% dolomite exhibited good performances such as porosity 44.6%, mean pore size 4.7 μm, bending strength 47.6 MPa, water permeability 10.76 m3 m−2 h−1 bar−1, as well as good chemical resistance. This work provides opportunities to develop cost-effective ceramic supports with controllable pore size, porosity, and high strength for high performance membranes.

Similar content being viewed by others

References

L. Cot, A. Ayral, J. Durand, C. Guizard, N. Hovnanian, A. Julbe, A. Larbot, Solid State Sci. 2, 313 (2000). doi:10.1016/S1293-2558(00)00141-2

J.M. Benito, A. Conesa, F. Rubio, M.A. Rodŕguez, J. Eur. Ceram. Soc. 25, 1895 (2005). doi:10.1016/j.jeurceramsoc.2004.06.016

S. Khemakhem, A. Larbot, L. Cot, in Proceedings of the 8th International Conference on Inorganic Membranes (ICIM8) (Cicinnati, OH, USA, 2004), p. 249

M.R. Weir, E. Rutinduka, C. Detellier, C.Y. Feng, Q. Wang, T. Matsuura, R. Le VanMao, J. Membr. Sci. 182, 41 (2001). doi:10.1016/S0376-7388(00)00547-0

R. Le Van Mao, E. Rutinduka, C. Detellier, P. Gougay, V. Hascoet, S. Tavakoliyan, S.V. Hoa, T. Matsuura, J. Mater. Chem. 9, 783 (1999). doi:10.1039/a806624h

Y. Dong, S. Chen, X. Zhang, J. Yang, X. Liu, G. Meng, J. Membr. Sci. 281, 592 (2006). doi:10.1016/j.memsci.2006.04.029

Y. Dong, J. Diwu, X. Feng, X. Liu, G. Meng, J. Alloys Comp. 460, 651 (2008)

B.F. Jones, E. Galan, in Reviews in Mineralogy, Hydrous Phyllosilicates 19, ed. by S.W. Bailey (Mineralogical Society of America, Washington, 1988), pp. 631–674

J.L. Peŕez-Rodriguez, E. Ga, Therm. Anal. 42, 131 (1994). doi:10.1007/BF02546996

R. Cool, A. Clearfiled, V. Mariagnanam, L.J.M. Ellistrem, R.M. Crooks, E.F. Vansant, J. Mater. Chem. 7, 443 (1997). doi:10.1039/a606129j

S. Khemakhem, A. Larbot, R. Ben Amar, Ceram. Int. (2008). doi:10.1016/j.ceramint.2007.09.117

S. Khemakhem, A. Larbot, R. Ben Amar, Desalination 200, 307 (2006). doi:10.1016/j.desal.2006.03.327

S. Vercauteren, M. Vayer, H. Van Damme, J. Luyten, R. Leysen, E.F. Vansant, Colloids Surf. A Physicochem. Eng. Asp. 138, 367 (1998). doi:10.1016/S0927-7757(97)00143-X

T. Mohammadi, A. Pak, Separ. Purif. Tech. 30, 241 (2003). doi:10.1016/S1383-5866(02)00146-6

A. Belouatek, N. Benderdouche, A. Addou, A. Ouagued, N. Bettahar, Microporous Mesoporous Mater. 85, 163 (2005). doi:10.1016/j.micromeso.2005.06.007

B.K. Nandi, R. Uppaluri, M.K. Purkait, Appl. Clay. Sci. 42, 102 (2008). doi:10.1016/j.clay.2007.12.001

A. Harabi, A. Mecif, A. Achour, S.E. Barama, in Ninth CIMTEC Proceedings, Ceramics: Getting into the 2000’s, Part B, ed. by P. Vincenzini (Materials Research Society, Pittsburg, 1999), pp. 871–878

A. Harabi, A. Achour, J. Mater. Sci. Lett. 18, 955 (1999). doi:10.1023/A:1006698704468

F. Bouzerara, A. Harabi, S. Achour, A. Larbot, J. Eur. Ceram. Soc. 26, 1663 (2006). doi:10.1016/j.jeurceramsoc.2005.03.244

S. Chandrasekhar, S. Ramaswamy, Appl. Clay Sci. 21, 133 (2002). doi:10.1016/S0169-1317(01)00083-7

Y. Chen, M. Wang, M. Hon, J. Afr. Earth Sci. 46, 245 (2006). doi:10.1016/j.jafrearsci.2006.06.002

A. Yamuna, S. Devanarayanan, M. Lalithambika, J. Am. Ceram. Soc. 85, 1409 (2002)

R.S. Roth, T. Negas, L.P. Cook, Phase Diagrams for Ceramists (The American Ceramic Society, New York, 1981), pp. 212–217

Q. Zhang, Y. Luo, China Ceram. 34, 39 (1998)

Y. Dong, X. Feng, D. Dong, S. Wang, J. Yang, J. Gaoa, X. Liu, G. Meng, J. Membr. Sci. 304, 65 (2007). doi:10.1016/j.memsci.2007.06.058

S. Masmoudi, A. Larbot, H. El Feki, R. Ben Amar, Ceram. Int. 33, 337 (2007). doi:10.1016/j.ceramint.2005.10.001

N. Moudden, A. Elghazouali, S. Rakib, M. Sghyar, M. Rafiq, A. Larbot, L. Cot, Ann. Chim. Sci. Mater. 26, 5 (2001). doi:10.1016/S0151-9107(01)80041-6

A.J. Burggraaf, L. Cot, Fundamentals of Inorganic Membrane Science and Technology (Elsevier, Amsterdam, 1996), p. 185

Acknowledgment

This work was financially supported by the Ministry of Science and Technology of China based on the Sino-France International Science and Technology Cooperation Program (Project No. 2005DFA50450), the Natural Science Foundation of Jiangxi Province (Project No. 2007GZC0799), and the Jiangxi Provincial Department of Education (Project No. [2006]309), China. The editor and reviewers are gratefully acknowledged for their good advice.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, J., Zhang, X., Wang, Y. et al. Elaboration and characterization of tubular macroporous ceramic support for membranes from kaolin and dolomite. J Porous Mater 17, 1–9 (2010). https://doi.org/10.1007/s10934-008-9258-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-008-9258-z