Abstract

With the increasing dominance of monoclonal antibodies (mAbs) in the biopharmaceutical industry and smaller antibody fragments bringing notable advantages over full-length antibodies, it is of considerable significance to choose the most suitable production system. Although mammalian expression system has been the preferred choice in recent years for mAbs production, E. coli could be the favorable host for non-glycosylated small antibody fragments due to the emergence of new engineered E. coli strains capable of forming disulfide-bonds in their cytoplasm.

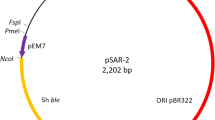

In this study, non-glycosylated anti-TNF-α Fab’ moiety of Certolizumab pegol, produced by periplasmic expression in E. coli in previous studies, was produced in the cytoplasm of E. coli SHuffle strain. The results indicated that it is biologically functional by testing the antigen-binding activity via indirect ELISA and inhibition of TNF-α induced cytotoxicity using MTT test. Major factors affecting protein production and, optimized culture conditions were examined by analyzing growth characteristics and patterns of expression in 24 h of post-induction cultivation and, optimization of culture conditions by response surface methodology considering temperature, time of induction and concentration of inducer in small (tube) and shake-flask scale. Based on the results, temperature had the most significant influence on functional protein yield while exerting different impacts in small and shake-flask scales, which indicated that cultivation volume is also an important factor that should be taken into account in optimization process. Furthermore, richness of medium and slower cellular growth rate improved specific cellular yield of functional protein by having a positive effect on the solubility of Fab' antibody.

Similar content being viewed by others

Data Availability

The datasets generated and analyzed during the current study are available from the corresponding authors on reasonable request.

References

Hua Q et al (2004) Analysis of gene expression in Escherichia coli in response to changes of growth-limiting nutrient in chemostat cultures. Appl Environ Microbiol 70(4):2354–2366

Graumann K, Premstaller A (2006) Manufacturing of recombinant therapeutic proteins in microbial systems. Biotechnol J Healthcare Nutr Technol 1(2):164–186

Georgiou G, Valax P (1996) Expression of correctly folded proteins in Escherichia coli. Curr Opin Biotechnol 7(2):190–197

Graham L, Beveridge T, Nanninga N (1991) Periplasmic space and the concept of the periplasm. Trends Biochem Sci 16(9):328–329

Stock JB, Rauch B, Roseman S (1977) Periplasmic space in Salmonella typhimurium and Escherichia coli. J Biol Chem 252(21):7850–7861

Wang YY et al (2011) Enhancement of excretory production of an exoglucanase from Escherichia coli with phage shock protein A (PspA) overexpression. J Microbiol Biotechnol 21(6):637–645

Lobstein J et al (2012) SHuffle, a novel Escherichia coli protein expression strain capable of correctly folding disulfide bonded proteins in its cytoplasm. Microb Cell Fact 11(1):753

Röthlisberger D, Honegger A, Plückthun A (2005) Domain interactions in the Fab fragment: a comparative evaluation of the single-chain Fv and Fab format engineered with variable domains of different stability. J Mol Biol 347(4):773–789

Antibody molecules having specificity for human necrosis factor alpha, and use thereof. WO 01/94585A1

Haaland, P.D., Experimental design in biotechnology. Vol. 105. 1989: CRC press.

Box GE, Wilson KB (1951) On the experimental attainment of optimum conditions. J Roy Stat Soc: Ser B (Methodol) 13(1):1–38

Myers RH et al (2004) Response surface methodology: a retrospective and literature survey. J Qual Technol 36(1):53–77

Yee L, Blanch H (1992) Recombinant protein expression in high cell density fed-batch cultures of Escherichia coli. Bio/Technology 10(12):1550–1556

Kram KE, Finkel SE (2015) Rich medium composition affects Escherichia coli survival, glycation, and mutation frequency during long-term batch culture. Appl Environ Microbiol 81(13):4442–4450

Marisch K et al (2013) Evaluation of three industrial Escherichia coli strains in fed-batch cultivations during high-level SOD protein production. Microb Cell Fact 12(1):58

Winter J et al (2000) Increased production of human proinsulin in the periplasmic space of Escherichia coli by fusion to DsbA. J Biotechnol 84(2):175–185

Moore JT et al (1993) Overcoming inclusion body formation in a high-level expression system. Protein Expr Purif 4(2):160–163

Hoffmann F et al (2004) Minimizing inclusion body formation during recombinant protein production in Escherichia coli at bench and pilot plant scale. Enzyme Microb Technol 34(3–4):235–241

Iafolla MA et al (2008) Dark proteins: effect of inclusion body formation on quantification of protein expression. Proteins Structure Function Bioinformatics 72(4):1233–1242

Siller E et al (2010) Slowing bacterial translation speed enhances eukaryotic protein folding efficiency. J Mol Biol 396(5):1310–1318

Yoon SK, Kang WK, Park TH (1994) Fed-batch operation of recombinant Escherichia coli containing trp promoter with controlled specific growth rate. Biotechnol Bioeng 43(10):995–999

Rezaie F et al (2017) Cytosolic expression of functional Fab fragments in Escherichia coli using a novel combination of dual SUMO expression cassette and EnBase® cultivation mode. J Appl Microbiol 123(1):134–144

Jhamb K, Sahoo DK (2012) Production of soluble recombinant proteins in Escherichia coli: effects of process conditions and chaperone co-expression on cell growth and production of xylanase. Biores Technol 123:135–143

Chen Y et al (2003) DnaK and DnaJ facilitated the folding process and reduced inclusion body formation of magnesium transporter CorA overexpressed in Escherichia coli. Protein Expr Purif 32(2):221–231

Mazaheri S et al (2020) Improvement of Certolizumab Fab′ properties by PASylation technology. Sci Rep 10(1):1–13

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

This study was based on the master’s thesis of A.T. which was conducted under the supervision of her mentors, L. N. and Y. T. who conceived the project and were in charge of overall direction and planning. A.T. was responsible for the major experimental work, preparation of the manuscript and design and analysis of the optimization process. S. M. contributed to construct design and ELISA setup. E. B. assisted in protein expression and purification. M. S. and S. D. contributed to the cellular assay and TNF-α supply, respectively. F. M. and B. B. provided critical feedback and assisted in revision of manuscript.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Ethical Approval

This article does not contain any studies with human participants or animals by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Talaei, A., Mazaheri, S., Bayat, E. et al. Production of Soluble and Functional Anti-TNF-α Fab' Fragment in Cytoplasm of E. coli: Investigating the Effect of Process Conditions on Cellular Biomass and Protein Yield Using Response Surface Methodology. Protein J 40, 786–798 (2021). https://doi.org/10.1007/s10930-021-09996-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10930-021-09996-3