Abstract

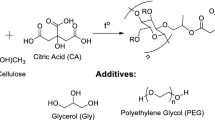

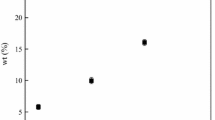

Hydroxypropyl methyl cellulose (HPMC) with controllable viscosity average molecular mass (Mη) and degree of substitution had been successfully synthesized in this article. α-cellulose was firstly methylated to be methyl cellulose (MC) by dimethyl sulphate (DMS). Then MC was hydroxypropylated to be HPMC by propylene oxide (PO). In this way, the end capping structure that methoxy group connected to terminal hydroxyl group of hydroxypropyl had been avoided. FT-IR,1H NMR and 13C NMR showed the successful synthesis of products with expected structure. The dilute hydrochloric acid was used to degrade HPMC to obtain a range of products with different Mη measured by ubbelohde viscometer. The rheological properties of HPMC solution with different molecular mass and concentrations were studied, including flow behavior index, thixotropy, entanglement concentration (C**), gelation temperature (Tgel), degelation temperature (Tsol). The results showed that the flow behavior index of HPMC solutions decreased with the increase of molecular mass and concentration, and gradually changed from Newtonian fluid to pseudoplastic fluid. In this article, Tgel and Tsol of HPMC both increased with the increase of molecular mass. When wt = 14%, Mη = 140 kDa, the maximum Tgel and Tsol was separately up to 70.18 °C and 46.81 °C. The effect of concentration on Tgel and Tsol was not noticeable. Tgel changed within 60 ± 2 °C and Tsol decreased from 40.56 °C to 35.72 °C as the concentration increased from 14 to 20%. These rheological studies are expected to provide data for subsequent processing and molding of HPMC capsules.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available on request from the corresponding author upon reasonable request.

References

Nurilmala M et al (2021) Pangasius fish skin and swim bladder as gelatin sources for hard capsule material. Int J Biomater 2021:6658002

Ding Y et al (2020) An alternative hard capsule prepared with the high molecular weight pullulan and gellan processing, characterization, and in vitro drug release. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2020.116172

He S et al (2023) Reversible cross-linking of gelatin by a disulphide-containing bis-succinimide for tunable degradation and release. Food Chemistry: X 18:100699

Mariia K et al (2022) Preparation of novel hard capsule using water-soluble polysaccharides and cellulose nanocrystals for drug delivery. J Pharmaceut Innov. https://doi.org/10.1007/s12247-022-09671-9

Zhu F (2018) Relationships between amylopectin internal molecular structure and physicochemical properties of starch. Trends Food Sci Technol 78:234–242

Ramli NA et al (2023) Evaluation of mechanical and thermal properties of carrageenan/hydroxypropyl methyl cellulose hard capsule. Can J Chem Eng 101(3):1219–1234

Arca HC et al (2018) Pharmaceutical applications of cellulose ethers and cellulose ether esters. Biomacromol 19(7):2351–2376

Ioelovich M (2023) Application of thermochemical method to determine the crystallinity degree of cellulose materials. Appl Sci-Basel. https://doi.org/10.3390/app13042387

Wang YF et al (2022) Hydroxypropyl methylcellulose hydrocolloid systems: effect of hydroxypropy group content on the phase structure, rheological properties and film characteristics. Food Chem 379:132075

You J et al (2022) Mild, rapid and efficient etherification of cellulose. Cellulose 29(18):9583–9596

Bilal M et al (2023) A comparative study of gelatin/HPMC/HA and Gel/HPMC/TCP nanocomposites for bone tissue regeneration. J Polym Environ 31(8):3381–3392

Bizymis A-P et al (2023) Contribution of hydroxypropyl methylcellulose to the composite edible films and coatings properties. Food Bioprocess Technol 16(7):1488–1501

Nigmatullin R et al (2019) Thermosensitive supramolecular and colloidal hydrogels via self-assembly modulated by hydrophobized cellulose nanocrystals. Cellulose 26(1):529–542

Perez-Robles S et al (2022) Effect on the thermo-gelation process of the degree and molar substitution of HPMC polymer hydrogels. Macromol Symp 405(1):2100277

Fettaka M et al (2011) Thermo sensitive behavior of cellulose derivatives in dilute aqueous solutions: from macroscopic to mesoscopic scale. J Colloid Interface Sci 357(2):372–378

Bizmark N et al (2022) Hysteresis in the thermally induced phase transition of cellulose ethers. Soft Matter 18(33):6254–6263

Barham AS et al (2015) Moisture diffusion and permeability characteristics of hydroxypropylmethylcellulose and hard gelatin capsules. Int J Pharm 478(2):796–803

Almeida N et al (2018) The effect of kappa carrageenan and salt on thermoreversible gelation of methylcellulose. Polym Bull 75(9):4227–4243

Yang N et al (2020) Moisture sorption and desorption properties of gelatin, HPMC and pullulan hard capsules. Int J Biol Macromol 159:659–666

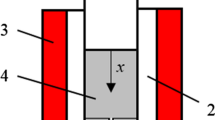

He C et al (2023) Drying process of HPMC-based hard capsules: visual experiment and mathematical modeling. Gels. https://doi.org/10.3390/gels9060463

Ding H et al (2021) Effect of formula factors on the properties of HPMC plant hollow capsule film. Drug Dev Ind Pharm 47(7):1052–1063

Szczgielska A et al (2002) Cellulose ethers-preparation, application and market situation. Przem Chem 81(11):704–707

Seddiqi H et al (2021) Cellulose and its derivatives: towards biomedical applications. Cellulose 28(4):1893–1931

Tian L et al (2021) Development and properties of zein/Tremella fuciformis polysaccharides blend as a hard capsule material. J Appl Polym Sci 138(46):51379

Mansour OY et al (1994) Variables affecting the methylation reactions of cellulose. J Appl Polym Sci 54:519–524

Abdel-Halim ES, Al-Deyab SS (2011) Utilization of hydroxypropyl cellulose for green and efficient synthesis of silver nanoparticles. Carbohyd Polym 86(4):1615–1622

Goodwin DJ et al (2011) Ultrasonic degradation for molecular weight reduction of pharmaceutical cellulose ethers. Carbohyd Polym 83(2):843–851

Akinosho H et al (2013) Hydroxypropyl methylcellulose substituent analysis and rheological properties. Carbohyd Polym 98(1):276–281

Zhou JP et al (2004) Synthesis and characterization of cellulose derivatives prepared in NaOH/urea aqueous solutions. J Polym Sci Part a-Polym Chem 42(23):5911–5920

Viriden A et al (2010) The effect of substitution pattern of HPMC on polymer release from matrix tablets. Int J Pharm 389(1–2):147–156

Oliveira RL et al (2015) Synthesis and characterization of methylcellulose produced from bacterial cellulose under heterogeneous condition. J Braz Chem Soc 26(9):1861–1870

Viera RGP et al (2007) Synthesis and characterization of methylcellulose from sugar cane bagasse cellulose. Carbohyd Polym 67(2):182–189

Vieira JG et al (2012) Synthesis and characterization of methylcellulose from cellulose extracted from mango seeds for use as a mortar additive. Polimeros-Ciencia E Tecnologia 22(1):80–87

George M et al (2016) Surface and thermal enhancement of the cellulosic component of thermo mechanical pulp using a rapid method: Iodomethane modification. Carbohyd Polym 142:300–308

Nakagawa A et al (2012) 2-O-Methyl- and 3,6-Di-O-methyl-cellulose from natural cellulose: synthesis and structure characterization. Biomacromol 13(9):2760–2768

Zhang Y et al (2017) Homogeneous alkalization of cellulose in N-methylmorpholine-N-oxide/water solution. Cellulose 24(3):1235–1245

Joshi G et al (2019) Chemical modification of waste paper: an optimization towards hydroxypropyl cellulose synthesis. Carbohyd Polym 223:115082

Nguyen HSH et al (2020) Evolution of the molar mass distribution of oat β-glucan during acid catalyzed hydrolysis in aqueous solution. Chem Eng J 382:122863

Huang Y-B, Fu Y (2013) Hydrolysis of cellulose to glucose by solid acid catalysts. Green Chem 15(5):1095–1111

Chen X et al (2009) Rheology of concentrated cellulose solutions in 1-butyl-3-methylimidazolium chloride. J Polym Environ 17(4):273–279

Zhao L et al (2021) Using viscosity modifying admixture to reduce diffusion in cement-based materials: effect of molecular mass. Construct Building Mater. https://doi.org/10.1016/j.conbuildmat.2021.123207

Purnomo EH et al (2023) Determination of viscosity and critical concentrations of commercial low methoxyl pectin. Int J Food Eng 19(10):467–477

Ferrarezi MMF et al (2013) Investigation of cellulose acetate viscoelastic properties in different solvents and microstructure. Eur Polym J 49(9):2730–2737

Su R et al (2021) A study of rheological properties of cellulose diacetate in acetone solution at low and high shear rates. Polym Eng Sci 61(11):2910–2917

Hasheminya S-M, Dehghannya J (2023) Physicochemical, thermal and rheological characterization of novel biopolymer gum exudate from Astragalus sarcocolla. J Polym Environ 31(3):965–975

Smith JA et al (2014) Shear dependent viscosity of poly(ethylene oxide) in two protic ionic liquids. J Colloid Interface Sci 430:56–60

Martin-Gomez A et al (2018) Active brownian filamentous polymers under shear flow. Polymers. https://doi.org/10.3390/polym10080837

Schmidt J et al (2003) Rheological and rheo-optical investigation of cellulose ethers in aqueous solution. Cellulose 10(1):13–26

Benchabane A, Bekkour K (2008) Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid Polym Sci 286(10):1173–1180

Lundqvist R (2005) Universal suspension hydrodynamics: molecular characterization of hydroxypropyl methylcellulose. Int J Polym Anal Charact 10(5–6):259–292

Heckl MP et al (2023) Relation between deformation and relaxation of hydrocolloids-starch based bio-inks and 3D printing accuracy. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2022.108326

Dolz-Planas M et al (1991) Thixotropy of different concentrations of microcrystalline cellulose: sodium carboxymethyl cellulose gels. J Pharm Sci 80(1):75–79

Zhang L et al (2021) Effect of curdlan on the rheological properties of hydroxypropyl methylcellulose. Foods. https://doi.org/10.3390/foods10010034

Rudraraju VS, Wyandt CM (2005) Rheology of microcrystalline cellulose and sodiumcarboxymethyl cellulose hydrogels using a controlled stress rheometer: part II. Int J Pharm 292(1–2):63–73

Talasaz AHH et al (2008) In situ gel forming systems of poloxamer 407 and hydroxypropyl cellulose or hydroxypropyl methyl cellulose mixtures for controlled delivery of vancomycin. J Appl Polym Sci 109(4):2369–2374

Coughlin ML et al (2021) Methyl cellulose solutions and gels: fibril formation and gelation properties. Prog Polym Sci. https://doi.org/10.1016/j.progpolymsci.2020.101324

Viriden A et al (2009) Influence of substitution pattern on solution behavior of hydroxypropyl methylcellulose. Biomacromol 10(3):522–529

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

KY: wrote the main manuscript text, designed and performed the experiments. YTZ and MJL: reviewed and edited the text. QZH: edited pictures of writing-original draft. DL: Writing—review & editing, supervision, methodology, validation. HZ: Resources, review, project administration, funding acquisition. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no confict of interest.

Additional information

Publisher's Note

Springer nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuan, K., Zhao, Y., Hu, Q. et al. Controllable Synthesis and Rheological Characterization of Hydroxypropyl Methyl Cellulose. J Polym Environ (2024). https://doi.org/10.1007/s10924-024-03293-7

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-024-03293-7