Abstract

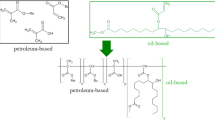

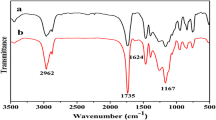

The current work was developed focusing on the synthesis of new polymeric latexes through the in reactor oxidative polymerisation of chia oil alkyd resins using the miniemulsion process. These latexes have potential applications, primarily in coating applications. Initially, an oil length mixture was obtained from chia oil through saponification and acidification reactions. The resulting mixture was characterized by 1H-NMR and 13C-NMR, confirming the presence of unsaturation and the characteristic functional groups associated with this compound. Phthalic anhydride and glycerol (esterification reaction) were used in the synthesis of alkyd resin. Alkyd resins were obtained by varying the oil length content in its composition: 30% wt% oil length alkyd resin is called short alkyd resin, 43% wt% oil length is medium resin and 64% wt% is the long alkyd resin. The 1H NMR spectra of alkyd resins showed peaks indicative of the presence of groups coming from phthalic anhydride and glycerol, as well as unsaturations that varied in intensity according to the size of the resin (short, medium or long). The miniemulsions were obtained from alkyd resins demonstrating colloidal stability over 90 days and with stable miniemulsions the oxidative polymerisation of the alkyd resins was carried out in a high-pressure reactor with temperature and pressure control and in the presence of the radicalinitiator benzoyl peroxide (BPO) and oxygen. Based on 1H-NMR analysis, polymers are formed through the oxidative polymerisation of alkyd resins from chia oil using the miniemulsion process. These polymers can be used as a paint base with a low solvent fraction or no solvent, depending on the application, and without using heavy metals-based catalysts.

Similar content being viewed by others

References

Thanamongkollit N (2008) Modification of Tung oil for bio-based coating. University of Akron

Silva CG, Zanette VAS (2016) Chia (Salvia hispanica L.) oil extraction using different organic solvents: oil yield, fatty acids profile and technological analysis of defatted meal. Int Food Res J 23(3):998–1004

Segura-Campos MR, Ciau-Solís N, Rosado-Rubio G, Chel-Guerrero L, Betancur-Ancona D (2014) Chemical and Functional properties of Chia seed (Salvia hispanica L.) Gum. Int J Food Sci, : p. 1–5

Alam M et al (2014) Vegetable oil based eco-friendly coating materials: a review article. Arab J Chem 7(4):469–479

Hofland A (2012) Alkyd resins: from down and out to alive and kicking. Prog Org Coat 73:274–282

Rehman K, Waheed FF, Akash I (2018) Prevalence of exposure of heavy metals and their impact on health consequences. J Cell Biochem 119(1):157–184

Burghardt TE, Pashkevich A (2018) Emissions of volatile Organic compounds from road marking paints. Atmos Environ 193:153–157

Pandey P (2020) Degradation of paints and its microbial effect on health and environment. J Crit Reviews 7(19):4879–4884

Sorokin AEB, Gorbachev SN (2019) Environmental impact of paints in high-tech production. Russ Eng Res 39(9):816–819

Dai H et al (2017) VOC characteristics and inhalation health risks in newly renovated residences in Shanghai, China. Sci Total Environ 577:73–83

Burghardt TE, Pashkevich A, Żakowska L (2016) Influence of volatile organic compounds emissions from road marking paints on ground-level ozone formation: case study of Kraków, Poland. Transp Res Procedia 14:714–723

Ifijen IH, Odi HD, Maliki M et al (2021) Correlative Stud Prop Rubber seed Soybean oil-based Alkyd Resins Their Blends 18:459–467

Mutar AL, Hassan NMA (2017) Synthesis and characterization of New Alkyd resins (short, medium and Long) 3 based on Sunflower Oil and linoleic acid as Binder for paints. Int J Chem Petrochemical Technol 7(1):1–16

Yong MY et al (2023) Utilization of liquid epoxidized natural rubber as prepolymer and crosslinker in development of UV-curable palm oil-based alkyd coating. Reactive Funct Polym 191:105658

Villada Y et al (2023) Alkyd-urethane resins based on castor oil: synthesis, characterization and coating properties. Prog Org Coat 180:107556

Kartaloğlu N et al (2023) Waterborne hybrid (alkyd/styrene acrylic) emulsion polymers and exterior paint applications. J Coat Technol Res 20(5):1621–1637

Hadzich A et al (2023) NMR and GPC Analysis of Alkyd Resins: influence of synthesis method, Vegetable Oil and Polyol Content. Polymers 15. https://doi.org/10.3390/polym15091993

Das P et al (2021) Synthesis and characterization of neem (Azadirachta indica) seed oil-based alkyd resins for efficient anticorrosive coating application. Polym Bull 78(1):457–479

Ong HR et al (2018) Formation of CuO Nanoparticle in Glycerol and Its Catalytic Activity for Alkyd Resin Synthesis Materials Today: Proceedings, 5(1, Part 3): p. 3165–3175

Hofland A (2012) Alkyd resins: from down and out to alive and kicking. Prog Org Coat 73(4):274–282

Neto WS et al (2020) Experimental evaluation of the Miniemulsion polymerization of Vinyl Pivalate: the role of the main process variables. Macromol React Eng, 15(2)

Thickett SC, Gilbert RG (2007) Emulsion polymerization: state of the art in kinetics and mechanisms. Polymer 48(24):6965–6991

Yilmazoglu M, Erciyes AT (2018) Styrenation of air blown linseed oil via RAFT–mediated miniemulsion polymerization. Prog Org Coat 114:1–8

Meneghetti SM et al (1998) Substitution of lead catalysts by zirconium in the oxidative polymerization of linseed oil. Prog Org Coat 33(3–4):219–224

Hare CH (1994) Protective coatings: fundamentals of chemistry and composition, vol 1. Society of Protective Coatings, p 514

Payne HF (1954) Organic coating technology, vol 120. Wiley, p 422

Wicks ZW et al (2007) Binders based on polyisocyanates: polyurethanes Organic Coatings: Science and Technology, Third Edition, : p. 231–270

Glenn AF et al (2023) Exploiting the Use ofSalvia Hispanica L. (Chia) Oil as a renewable raw material to produce Air-Drying Alkyd resins: a comparative study. Macro Reaction Engineering

Glenn A, Jensen AT, Machado F Salvia hispanica L. (Chia) Oil as a potential renewable raw material for the production of Air-Dry Alkyd resins. Appl Polym Mater, 2021(3): p. 6186–6197

Anthony F, Glenn GFSB, Resende G, Jaques LL, Barroso RaíssaGMR (2023) Thainá Araruna, and Fabricio Machado, exploiting the Use ofSalvia Hispanica L. (Chia) Oil as a renewable raw material to produce Air-Drying Alkyd resins: a comparative study. Macro Reaction Engineering

Anthony Glenn ATJ, Machado F Salvia hispanica L. (Chia) Oil as a potential renewable raw material for the production of Air-Dry Alkyd resins. Appl Polym Mater, 2021(3): p. 6186–6197

Chen L-J et al (1997) Critical micelle concentration of mixed surfactant SDS/NP (EO) 40 and its role in emulsion polymerization. Colloids Surf a 122(1–3):161–168

Gooch JW (2002) Emulsification and polymerization of alkyd resins, vol 1. Springer Science & Business Media, p 223

Minatti E, Zanette D (1996) Salt effects on the interaction of poly (ethylene oxide) and sodium dodecyl sulfate measured by conductivity. Colloids Surf a 113(3):237–246

ASTM D 1639–90, Standard Method for Acid Value of Organic Materials Annual book of American society for testing and material standards, 1994. 6: p. 260-1

Ayerza R (1995) Oil content and fatty acid composition of Chia (Salvia hispanica L.) from five northwestern locations in Argentina. J Am Oil Chemists’ Soc 72:1079–1081

Imran M et al (2016) Fatty acids characterization, oxidative perspectives and consumer acceptability of oil extracted from pre-treated Chia (Salvia hispanica L.) seeds. Lipids Health Dis 15(1):162

Ixtaina VY et al (2011) Characterization of Chia seed oils obtained by pressing and solvent extraction. J Food Compos Anal 24(2):166–174

Coates W (1996) Production potential of Chia in northwestern Argentina. Ind Crops Prod 5(3):229–233

Junior P et al (2015) Development of methodology for the synthesis of poly (lactic acid-co-glycolic acid) for use in the production of radioactive sources. Polímeros 25(3):317–325

Badin C (2015) Síntese e caracterização de polímero híbrido acrílico-alquídico produzido por polimerização em miniemulsão. Universidade de São Paulo, p 123

Acknowledgements

This work was partially supported by Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) – Process 310829/2021-6, Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) – Finance Code 001, and Financiadora de Estudos e Projetos (FINEP) – grant nº 01.13.0315.02. The authors thank Fundação de Apoio à Pesquisa do Distrito Federal (FAPDF), Embrapa Agroenergia and DendePalm, for providing scholarships and research support. All authors kindly thank Jessé V. Santana for the help given during the DLS and NMR measurements.

Author information

Authors and Affiliations

Contributions

The manuscript was written through the contributions of all authors. S.B.G. and F.M. conceived and designed the experiments. T.M.G.F. carried out the experiments. R.T.A. wrote the main manuscript text. T.M.G.F., G.F.S.B., G.R., R.G.M.R.B., T.A., S.B.G. and F.M. analysed the data and reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Florindo, T.M.G., Brito, G.F.S., Resende, G. et al. Valorisation of Salvia Hispanica L. (Chia) Oil into Air-Drying Alkyd Resins: Towards Solvent-Free Nanodispersion Formulations and Their Oxidative Miniemulsion Polymerisation. J Polym Environ (2024). https://doi.org/10.1007/s10924-024-03206-8

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-024-03206-8