Abstract

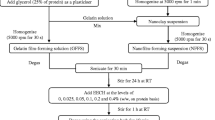

Laponite® (Lap) is a synthetic layered nanoclay that is considered a potential candidate for improving the physicochemical properties of gelatin films. However, there is limited information in the literature about the interaction between Lap platelets and gelatin chains and its impact on the physicochemical film properties. Therefore, the current research aimed to systematically study the mechanism of interaction and the effect of Lap on the physicochemical properties of gelatin films (moisture content, optical properties, water contact angle, surface energy, water adsorption, water solubility, water vapor permeability, and mechanical properties). Furthermore, gelatin films with Lap were applied as UV-barrier materials in grape juice. Gelatin films were produced by casting method containing 0, 3, 5, 10, and 15% of Lap (based on the weight of the biopolymer). The incorporation of Lap reduced the formation of the gelatin triple helix structure and consequently film crystallinity. Hydrogen bonds and electrostatic interactions could be the principal interactions between gelatin/glycerol/Lap. The incorporation of Lap increased the thickness and moisture content. Lap platelets were completely exfoliated and did not modify the color and opacity of the gelatin films. The UV-barrier capacity of the gelatin films was improved with the incorporation of Lap. Gelatin films with 15% Lap exhibited a transmittance decreases of 86% and 5% in ultraviolet (280 nm) and visible (470 nm) light, respectively. Furthermore, a reduction of 29% in film water solubility was observed with 15% Lap. Other properties such as water contact angle, surface free energy, water vapor permeability, and mechanical properties were not modified by the incorporation of Lap. Gelatin films containing Lap (15%) reduced the degradation of anthocyanins (50%) in grape juice exposed to UV light when compared with samples covered with gelatin films without Lap.

Similar content being viewed by others

References

Han JW, Ruiz-Garcia L, Qian JP, Yang XT (2018) Food packaging: a comprehensive review and future trends. Compr Rev Food Sci Food Saf 17:860–877. https://doi.org/10.1111/1541-4337.12343

Freitas EES, Dias ÊR, Albuquerque MMS et al (2023) Antioxidant films based on poly(lactic acid) incorporated with crude extract from Malpighia emarginata DC pomace for use in food packaging. Packag Technol Sci n/a. https://doi.org/10.1002/pts.2778

Chentir I, Aribi C, Tarchoun AF et al (2023) Development of functional active films from blend of gelatin with crude orange juice pomace pectin: test for packaging of virgin olive oil. Packag Technol Sci n/a. https://doi.org/10.1002/pts.2776

Perera KY, Jaiswal AK, Jaiswal S (2023) Biopolymer-based sustainable food packaging materials: challenges, solutions, and applications. Foods 12:2422

Juikar SK, Warkar SG (2023) Biopolymers for packaging applications: an overview. Packag Technol Sci 36:229–251. https://doi.org/10.1002/pts.2707

Vieira MGA, Silva MA, da Santos LO, Beppu MM (2011) Natural-based plasticizers and biopolymer films: a review. Eur Polym J 47:254–263. https://doi.org/10.1016/j.eurpolymj.2010.12.011

Flaker CHC, Lourenço RV, Bittante AMQB, Sobral PJA (2016) Montmorillonite dispersion in water affects some physical properties of gelatin-based nanocomposites films. Biointerface Res Appl Chem 6:1093–1098

Moeinpour F, Mohseni-Shahri FS (2023) Properties of Roselle and alizarin mixed loaded gelatin films as a pH-sensing indicator for shrimp freshness monitoring. Packag Technol Sci 36:483–493. https://doi.org/10.1002/pts.2724

Neira LM, Agustinelli SP, Ruseckaite RA, Martucci JF (2019) Shelf life extension of refrigerated breaded hake medallions packed into active edible fish gelatin films. Packag Technol Sci 32:471–480. https://doi.org/10.1002/pts.2450

Putsakum G, Lee DS, Suthiluk P, Rawdkuen S (2018) The properties of gelatin film-neem extract and its effectiveness for preserving minced beef. Packag Technol Sci 31:611–620. https://doi.org/10.1002/pts.2386

López-Angulo D, Bittante AMQB, Luciano CG et al (2020) Effect of Laponite® on the structure, thermal stability and barrier properties of nanocomposite gelatin films. Food Biosci 35:100596. https://doi.org/10.1016/j.fbio.2020.100596

Li X, Liu A, Ye R et al (2015) Fabrication of gelatin-laponite composite films: effect of the concentration of laponite on physical properties and the freshness ofmeat during storage. Food Hydrocoll 44:390–398. https://doi.org/10.1016/j.foodhyd.2014.10.014

Valencia GA, Lourenço RV, Bittante AMQB, Sobral PJA (2016) Physical and morphological properties of nanocomposite films based on gelatin and laponite. Appl Clay Sci 124–125:260–266. https://doi.org/10.1016/j.clay.2016.02.023

Nicolai T, Cocard S (2000) Light scattering study of the dispersion of laponite light scattering study of the dispersion of Laponite. 16. https://doi.org/10.1021/la9915623

da Silva MN, Fonseca J, de Feldhaus M HK, et al (2019) Physical and morphological properties of hydroxypropyl methylcellulose films with curcumin polymorphs. Food Hydrocoll 97:105217. https://doi.org/10.1016/j.foodhyd.2019.105217

Suderman N, Isa MIN, Sarbon NM (2018) Characterization on the mechanical and physical properties of chicken skin gelatin films in comparison to mammalian gelatin films. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/440/1/012033

Ahammed S, Liu F, Khin MN et al (2020) Improvement of the water resistance and ductility of gelatin film by zein. Food Hydrocoll 105:105804. https://doi.org/10.1016/j.foodhyd.2020.105804

Etxabide A, Yang Y, Maté JI et al (2022) Developing active and intelligent films through the incorporation of grape skin and seed tannin extracts into gelatin. Food Packag Shelf Life 33:100896. https://doi.org/10.1016/j.fpsl.2022.100896

Luchese CL, Sperotto N, Spada JC, Tessaro IC (2017) Effect of blueberry agro-industrial waste addition to corn starch-based films for the production of a pH-indicator film. Int J Biol Macromol 104:11–18. https://doi.org/10.1016/j.ijbiomac.2017.05.149

Barbosa ML, Oliveira LMd, Paiva R et al (2023) Evaluation the potential of onion/laponite composites films for sustainable food packaging with enhanced uv protection and antioxidant capacity. Molecules. https://doi.org/10.3390/molecules28196829

Liu Q, Li Y, Xing S et al (2022) Genipin-crosslinked amphiphilic chitosan films for the preservation of strawberry. Int J Biol Macromol 213:804–813. https://doi.org/10.1016/j.ijbiomac.2022.06.037

Ortega F, Giannuzzi L, Arce VB, García MA (2017) Active composite starch films containing green synthetized silver nanoparticles. Food Hydrocoll 70:152–162. https://doi.org/10.1016/j.foodhyd.2017.03.036

Pulla-Huillca PV, Gomes A, Quinta Barbosa Bittante AM et al (2021) Wettability of gelatin-based films: the effects of hydrophilic or hydrophobic plasticizers and nanoparticle loads. J Food Eng 297:110480. https://doi.org/10.1016/j.jfoodeng.2021.110480

Guettler BE, Moresoli C, Simon LC (2013) Contact angle and surface energy analysis of soy materials subjected to potassium permanganate and autoclave treatment. Ind Crops Prod 50:219–226. https://doi.org/10.1016/j.indcrop.2013.06.035

Karbowiak T, Debeaufort F, Voilley A (2006) Importance of surface tension characterization for food, pharmaceutical and packaging products: a review. Crit Rev Food Sci Nutr 46:391–407. https://doi.org/10.1080/10408390591000884

DIVERSIFIED Enterprises (2023) Accu Dyne test. https://www.accudynetest.com/surface_tension_table.html?sortby=sort_st_disp

Bialopiotrowicz T, Jańczuk B (2002) Surface properties of gelatin films. Langmuir 18:9462–9468. https://doi.org/10.1021/la0201624

Wan S, Liu Q, Yang D et al (2023) Characterization of high amylose corn starch-cinnamaldehyde inclusion films for food packaging. Food Chem 403:134219. https://doi.org/10.1016/j.foodchem.2022.134219

Wang K, Wang W, Ye R et al (2017) Mechanical and barrier properties of maize starch–gelatin composite films: effects of amylose content. J Sci Food Agric 97:3613–3622. https://doi.org/10.1002/jsfa.8220

Fonseca J, de Pabón M, Nandi NYL et al (2021) Gelatin-TiO2-coated expanded polyethylene foam nets as ethylene scavengers for fruit postharvest application. Postharvest Biol Technol 180:111602. https://doi.org/10.1016/j.postharvbio.2021.111602

Karaoglan HA, Keklik NM, Develi Isıklı N (2019) Degradation kinetics of anthocyanin and physicochemical changes in fermented turnip juice exposed to pulsed UV light. J Food Sci Technol 56:30–39. https://doi.org/10.1007/s13197-018-3434-1

Merz B, Capello C, Leandro GC et al (2020) A novel colorimetric indicator film based on chitosan, polyvinyl alcohol and anthocyanins from jambolan (Syzygium cumini) fruit for monitoring shrimp freshness. Int J Biol Macromol 153:625–632. https://doi.org/10.1016/j.ijbiomac.2020.03.048

Ruiz-Martínez IG, Rodrigue D, Arenas-Ocampo ML et al (2022) Production and characterization of gelatin biomaterials based on agave microfibers and bentonite as reinforcements. Foods 11:1–23. https://doi.org/10.3390/foods11111573

Chen Y, Lu W, Guo Y et al (2018) Superhydrophobic coatings on gelatin-based films: fabrication, characterization and cytotoxicity studies. RSC Adv 8:23712–23719. https://doi.org/10.1039/c8ra04066d

Zeraatpishe L, Mohebali A, Abdouss M (2019) Fabrication and characterization of biocompatible pH responsive halloysite nanotubes grafted with sodium alginate for sustained release of phenytoin sodium. New J Chem 43:10523–10530. https://doi.org/10.1039/c9nj00976k

Gutiérrez TJ, Valencia GA (2021) Reactive extrusion-processed native and phosphated starch-based food packaging films governed by the hierarchical structure. Int J Biol Macromol 172:439–451. https://doi.org/10.1016/j.ijbiomac.2021.01.048

Esmonde-White K (2014) Raman spectroscopy of soft musculoskeletal tissues. Appl Spectrosc 68:1203–1218. https://doi.org/10.1366/14-07592

Valencia GA, Luciano CG, Lourenço RV et al (2019) Morphological and physical properties of nano-biocomposite films based on collagen loaded with laponite®. Food Packag Shelf Life 19:24–30. https://doi.org/10.1016/j.fpsl.2018.11.013

Valencia GA, Djabourov M, Carn F, Sobral PJA (2018) Novel insights on swelling and dehydration of laponite. Colloids Interface Sci Commun 23:1–5. https://doi.org/10.1016/j.colcom.2018.01.001

Chacon WDC, Lima KT, Valencia S, Henao GA (2020) Physicochemical properties of potato starch nanoparticles produced by anti-solvent precipitation. Starch/Stärke. https://doi.org/10.1002/star.202000086.This

Sobral PJA, Menegalli FC, Hubinger MD, Roques MA (2001) Mechanical, water vapor barrier and thermal properties of gelatin-based edible films. Food Hydrocoll 15:423–432

Andretta R, Luchese CL, Tessaro IC, Spada JC (2019) Development and characterization of pH-indicator films based on cassava starch and blueberry residue by thermocompression. Food Hydrocoll 93:317–324. https://doi.org/10.1016/j.foodhyd.2019.02.019

Wittaya T (2012) Protein-based edible films: characteristics and improvement of properties. In: Eissa AA (ed) Structure and function of food engineering. IntechOpen, Rijeka

Ezati P, Khan A, Priyadarshi R et al (2023) Biopolymer-based UV protection functional films for food packaging. Food Hydrocoll 142:108771. https://doi.org/10.1016/j.foodhyd.2023.108771

Bonilla J, Poloni T, Lourenço RV, Sobral PJA (2018) Antioxidant potential of eugenol and ginger essential oils with gelatin/chitosan films. Food Biosci 23:107–114. https://doi.org/10.1016/j.fbio.2018.03.007

Guzman-Puyol S, Benítez JJ, Heredia-Guerrero JA (2022) Transparency of polymeric food packaging materials. Food Res Int. https://doi.org/10.1016/j.foodres.2022.111792

Prochon M, Dzeikala O (2021) Biopolymer composites as an alternative to materials for the production of ecological packaging. Polymers (Basel) 13:1–19. https://doi.org/10.3390/polym13040592

Cerqueira MA, Lima ÁM, Teixeira JA et al (2009) Suitability of novel galactomannans as edible coatings for tropical fruits. J Food Eng 94:372–378. https://doi.org/10.1016/j.jfoodeng.2009.04.003

Moncayo D, Buitrago G, Algecira N (2013) The surface properties of biopolymer-coated fruit: a review. Ing E Investig 33:11–16

Rawdkuen S, Sai-Ut S, Benjakul S (2010) Properties of gelatin films from giant catfish skin and bovine bone: a comparative study. Eur Food Res Technol 231:907–916. https://doi.org/10.1007/s00217-010-1340-5

Farahnaky A, Dadfar SMM, Shahbazi M (2014) Physical and mechanical properties of gelatin-clay nanocomposite. J Food Eng 122:78–83. https://doi.org/10.1016/j.jfoodeng.2013.06.016

Monteiro Fritz AR, de Matos Fonseca J, Trevisol TC, Fagundes C, Valencia GA (2019) Active, eco-friendly and edible coatings in the post-harvest–a critical discussion. In: Gutiérrez T (eds) Polymers for agri-food applications. Springer, Cham. https://doi.org/10.1007/978-3-030-19416-1_22

Acknowledgements

W.D.C. Chacon gratefully acknowledges the Fundação de Amparo à Pesquisa e Inovação do Estado de Santa Catarina (FAPESC) for the PhD fellowship (3003/2021). E.D.S. Araujo gratefully acknowledges the CAPES (Coordination for the Improvement of Higher Education Personnel) for the PhD fellowship. G. A. Valencia would like to thank the National Council for Scientific and Technological Development (CNPq) (grant 302434/2022-4) for financial support. The authors gratefully acknowledge the Federal University of Santa Catarina.

Funding

This work was supported by the National Council for Scientific and Technological Development (CNPq) (Grant 302434/2022-4).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception, design, and methodology definition. WDCC and EDA conducted the formal analysis, and curated and investigated the data. JMF and ARM Reviewed and edited the manuscript. GAV wrote the main manuscript text, and reviewed/edited the final version of this manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chacon, W.D.C., dos Santos Araujo, E., de Matos Fonseca, J. et al. Understanding the Interaction Between Gelatin and a Layered Silicate and Its Impact on the Physicochemical Properties of Films Produced by Casting. J Polym Environ (2024). https://doi.org/10.1007/s10924-024-03193-w

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-024-03193-w