Abstract

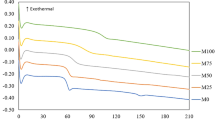

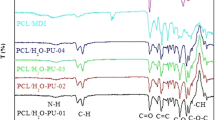

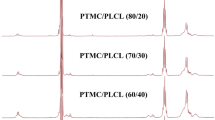

Currently, the preparation and application of bio-based thermoplastic polyurethane (TPU) are hot research topics in the field of polyurethane. In the present work, a series of polylactic acid (PLA)-based TPUs were synthesized using bio-based PLA and 4,4’-methylene diphenyl diisocyanate (MDI). The effects of three chain extenders, including 1,3-propanediol (PDO, PD), 1,4-butanediol (BDO, BD), and 1,6-hexanediol (HDO, HD), on the characteristics and properties of PLA-based TPUs were investigated. The successful synthesis of PLA-based TPUs was confirmed by the absence of isocyanate groups and the presence of characteristic peaks corresponding to urethane and other functional groups. The analyses revealed the potential for greater crystallization in the PLA-BD and PLA-HD series. Among the examined groups, the PLA-HD variant with a 55% hard segment content displayed the highest molecular weight and fracture stress, and an appropriate elongation value, indicating its suitability for specific applications. The study also investigated the stress relaxation rates and residual forces and found them to be within clinically acceptable ranges. These findings demonstrate the potential of these synthesized TPUs for orthodontic applications, with the ability to tailor mechanical properties by adjusting hard segment contents and modifying chain extenders.

Similar content being viewed by others

References

Lombardo L, Martines E, Mazzanti V, Arreghini A, Mollica F, Siciliani G (2016) Stress relaxation properties of four orthodontic aligner materials: a 24-hour in vitro study. Angle Orthod 87:11–18

Zhang N, Bai Y, Ding X, Zhang Y (2011) Preparation and characterization of thermoplastic materials for invisible orthodontics. Dent Mater J 30:954–959

Pazzini L, Cerroni L, Pasquantonio G, Pecora A, Mussi V, Rinaldi A, Mecheri B, Licoccia S, Maiolo L (2018) Mechanical properties of two generations of teeth aligners: change analysis during oral permanence. Dent Mater J 37:835–842

Lee SY, Kim H, Kim H-J, Chung CJ, Choi YJ, Kim S-J, Cha J-Y (2022) Thermo-mechanical properties of 3D printed photocurable shape memory resin for clear aligners. Sci Rep 12:6246

Fang D, Zhang N, Chen H, Bai Y (2013) Dynamic stress relaxation of orthodontic thermoplastic materials in a simulated oral environment. Dent Mater J 32:946–951

Kohda N, Iijima M, Muguruma T, Brantley WA, Ahluwalia KS, Mizoguchi I (2013) Effects of mechanical properties of thermoplastic materials on the initial force of thermoplastic appliances. Angle Orthod 83:476–483

Delebecq E, Pascault J-P, Boutevin B, Ganachaud F (2013) On the versatility of urethane/urea bonds: reversibility, blocked isocyanate, and non-isocyanate polyurethane. Chem Rev 113:80–118

Lin S, Hwang K, Tsay S, Cooper SL (1985) Segmental orientation studies of polyether polyurethane block copolymers with different hard segment lengths and distributions. Colloid Polym Sci 263:128–140

Yanping Y (2018) The development of polyurethane. Mater Science: Mater Rev, 1

Ziegler W, Guttmann P, Kopeinig S, Dietrich M, Amirosanloo S, Riess G, Kern W (2018) Influence of different polyol segments on the crystallisation behavior of polyurethane elastomers measured with DSC and DMA experiments. Polym Test 71:18–26

Oh J, Kim YK, Hwang S-H, Kim H-C, Jung J-H, Jeon C-H, Kim J, Lim SK (2022) Preparation of Side-By-Side Bicomponent Fibers Using Bio Polyol Based Thermoplastic Polyurethane (TPU) and TPU/Polylactic Acid Blends, Fibers, 10 95

Charlon M, Heinrich B, Matter Y, Couzigné E, Donnio B, Avérous L (2014) Synthesis, structure and properties of fully biobased thermoplastic polyurethanes, obtained from a diisocyanate based on modified dimer fatty acids, and different renewable diols. Eur Polymer J 61:197–205

Oh J, Kim YK, Hwang S-H, Kim H-C, Jung J-H, Jeon C-H, Kim J, Lim SK (2022) Synthesis of thermoplastic polyurethanes containing bio-based polyester polyol and their fiber property, Polymers, 14 2033

Zhang L, Huang M, Yu R, Huang J, Dong X, Zhang R, Zhu J (2014) Bio-based shape memory polyurethanes (Bio-SMPUs) with short side chains in the soft segment. J Mater Chem A 2:11490–11498

Kahraman Y, Özdemir B, Kılıç V, Goksu YA, Nofar M (2021) Super toughened and highly ductile PLA/TPU blend systems by in situ reactive interfacial compatibilization using multifunctional epoxy-based chain extender. J Appl Polym Sci 138:50457

Tripathi N, Misra M, Mohanty AK (2021) Durable polylactic acid (PLA)-based sustainable engineered blends and biocomposites: recent developments, challenges, and opportunities. ACS Eng Au 1:7–38

Jašo V, Cvetinov M, Rakić S, Petrović ZS (2014) Bio-plastics and elastomers from polylactic acid/thermoplastic polyurethane blends. J Appl Polym Sci, 131

Wang W, Ping P, Chen X, Jing X (2006) Polylactide-based polyurethane and its shape-memory behavior. Eur Polymer J 42:1240–1249

Swetha TA, Bora A, Mohanrasu K, Balaji P, Raja R, Ponnuchamy K, Muthusamy G, Arun A (2023) A comprehensive review on polylactic acid (PLA)–Synthesis, processing and application in food packaging. Int J Biol Macromol, 123715

Cui B, Wu Q-Y, Gu L, Shen L (2016) -b. Yu, high performance bio-based polyurethane elastomers: Effect of different soft and hard segments. Chin J Polym Sci 34:901–909

Liu W-K, Zhao Y, Wang R, Luo F, Li J-S, Li J-H, Tan H (2018) Effect of chain extender on hydrogen bond and microphase structure of biodegradable thermoplastic polyurethanes. Chin J Polym Sci 36:514–520

Wang W, Ping P, Chen X, Jing X (2007) Shape memory effect of poly (L-lactide)‐based polyurethanes with different hard segments. Polym Int 56:840–846

Gu L, Cui B, Wu Q-Y, Yu H (2016) Bio-based polyurethanes with shape memory behavior at body temperature: Effect of different chain extenders. RSC Adv 6:17888–17895

Albilali AT, Baras BH, Aldosari MA (2023) Evaluation of Mechanical properties of different thermoplastic Orthodontic Retainer materials after Thermoforming and Thermocycling. Polymers 15:1610

I. ISO, 20795-1: 2013 Dentistry—Base Polymers—Part 1: Denture Base Polymers, ISO: Geneva, Switzerland, (2013)

Hariharan K, Majidi O, Kim C, Lee M, Barlat F (2013) Stress relaxation and its effect on tensile deformation of steels. Mater Des (1980–2015) 52:284–288

Oh J, Kim YK, Hwang S-H, Kim H-C, Jung J-H, Jeon C-H, Kim J, Lim SK (2022) Preparation of Side-By-Side Bicomponent Fibers Using Bio Polyol Based Thermoplastic Polyurethane (TPU) and TPU/Polylactic Acid Blends, Fibers, 10 95

Yilgor I, Yilgor E, Guler IG, Ward TC, Wilkes GL (2006) FTIR investigation of the influence of diisocyanate symmetry on the morphology development in model segmented polyurethanes. Polymer 47(11):4105–4114

Gang H et al (2017) Development of high performance polyurethane elastomers using vanillin-based green polyol chain extender originating from lignocellulosic biomass. ACS Sustain Chem Eng 5(6):4582–4588

Zhao X, Shou T, Liang R, Hu S, Yu P, Zhang L (2020) Bio-based thermoplastic polyurethane derived from polylactic acid with high-damping performance. Ind Crops Prod 154:112619

Ti Y, Wen Q, Chen D (2016) Characterization of the hydrogen bond in polyurethane/attapulgite nanocomposites. J Appl Polym Sci, 133, (9),

Brunette CM, Hsu SL, MacKnight WJ (1982) Hydrogen-bonding properties of hard-segment model compounds in polyurethane block copolymers. Macromolecules 15(1):71–77

VAN GORP JUDITHJ, Desalvo JOSEPHW, Miller ROBERT (2010) Susterra® propanediol-renewability, sustainability and differentiating performance in urethane applications. EI du Pont de Nemours and Company Experimental Station in Wilmington and DuPont Tate & Lyle Bio Products Company, LLC in London

Pourmohammadi-Mahunaki M et al (2022) Effect of chain extender length and molecular architecture on phase separation and rheological properties of ether-based polyurethanes. Polym Bull : 1–16

Acknowledgements

This research received funding from the University System of Taipei Joint Research Program, Taiwan, under grant number USTP-NTUT-TMU-112-07.

Author information

Authors and Affiliations

Contributions

Conceptualization, P.-W. P., Y.-H. L., W.-F. L. and Y.-Y. C.; methodology, P.-W. P., Y.-H. L., W.-F. L. and Y.-Y. C; data curation, L.-Y. W., Y.-W. Z. and Z.-Y. C.; validation, P.-W. P., Y.-H. L., W.-F. L. and Y.-Y. C., writing-original draft preparation, P.-W. P.; writing-review and editing, P.-W. P., Y.-H. L., L.-Y. Wang and Y.-Y. C.; visualization, L.-Y. W. and Y.-W. Z.; supervision, P.-W. P., Y.-H. L., W.-F. L. and Y.-Y. C.; funding acquisition, P.-W. P. and Y.-Y. C. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Peng, PW., Lee, YH., Wang, LY. et al. Tuning the Properties of Bio-based Thermoplastic Polyurethane Derived from Polylactic Acid by Varying Chain Extenders and Hard Segment Contents. J Polym Environ (2024). https://doi.org/10.1007/s10924-023-03183-4

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-023-03183-4