Abstract

The construction sector is a prominent resource-intensive industry on a global scale, contributing significantly to environmental challenges through material production and construction operations. Selecting sustainable and energy-efficient building materials is crucial, considering green sustainable construction. Over the past two decades, polyurethane (PU) technology has experienced remarkable progress and is emerging as a versatile alternative to traditional building materials, but concerns still arise due to the petrochemical origins of the PU feedstocks. This increasing demand for eco-friendly building materials has spurred significant advancements in the research, development, and utilization of bio-based polyurethane (BPU) within the construction industry. Responding to the global shift towards sustainable development, this study aims to systematically identify bio-based and sustainable sources of PU, analyse advancements in production processes, and evaluate their properties compared to conventional materials. The purpose of this study is addressed by conducting a literature review, wherein findings from a diverse range of current studies in the field are compiled and the specific application areas covered are PU foam, coating, sealants, concrete systems, adhesives and road construction. The results suggest that BPU present various possibilities, benefits, and challenges. The review underscores BPU as a sustainable alternative with comparable properties to traditional counterparts with insights into BPU market highlighting a promising future in construction. By highlighting potential challenges, this review emphasises avenues for new research. Providing a comprehensive analysis of BPU sources, performance, and applications in construction, it would serve as a valuable resource for researchers, aiding in identifying unexplored research areas, fostering industry collaborations, and recognizing the expanding scope of BPU in the field.

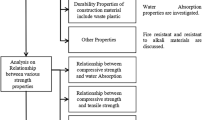

Graphical Abstract

Similar content being viewed by others

References

statista. Polyurethane global market volume 2030 (2023). https://www.statista.com/statistics/720341/global-polyurethane-market-size-forecast/

Szycher (2000) Szycher’s handbook of polyurethanes by Michael Szycher (Cardiotech International, Inc.). CRC Press, Boca Raton, FL. 1999. xviii + 673 pp. $129.95. ISBN 0-8493-0602-7. J Am Chem Soc 122:3983. https://doi.org/10.1021/ja004704k

Somarathna H, Raman S, Mohotti D, Mutalib A, Badri K (2018) The use of polyurethane for structural and infrastructural engineering applications: a state-of-the-art review. Constr Build Mater 190:995–1014

Das A, Mahanwar P (2020) A brief discussion on advances in polyurethane applications. Adv Ind Eng Polym Res 3:93–101

Li L, Yu T (2022) Curing comparison and performance investigation of polyurethane concrete with retarders. Constr Build Mater 326:126883

Horvath A (2004) Construction materials and the environment. Annu Rev Environ Resour 29:181–204

Petkar S (2014) Environmental impact of construction materials and practices. PhD Thesis, YCCE, Nagpur

Claisse PA (2016) Chapter 17 - Introduction to cement and concrete In: Claisse PA (ed) Civil engineering materials. Butterworth Heinemann, Boston, pp 155–162. https://www.sciencedirect.com/science/article/pii/B9780081002759000176

Ingham JP (2013) 5—Concrete. In: Ingham JP (ed) Geomaterials under the microscope. Academic Press, Boston, pp 75–120

Lim C et al (2020) Global trend of cement production and utilization of circular resources. J Energy Eng 29:57–63

Huang B et al (2020) A life cycle thinking framework to mitigate the environmental impact of building materials. One Earth 3:564–573

Garside M (2022) Cement production global 2021. https://www.statista.com/statistics/1087115/global-cement-production-volume/

Andrew RM (2018) Global CO2 emissions from cement production. Earth Syst Sci Data 10:195–217

Czarnecki L, Kaproń M, Van Gemert D (2013) Sustainable construction: challenges, contribution of polymers, research arena. Restor Build Monum 19:81–96

Lu G et al (2019) Development of a sustainable pervious pavement material using recycled ceramic aggregate and bio-based polyurethane binder. J Clean Prod 220:1052–1060

Ahmad W, Ahmad A, Ostrowski KA, Aslam F, Joyklad P (2021) A scientometric review of waste material utilization in concrete for sustainable construction. Case Stud Constr Mater 15:e00683

Report I (2020) Global energy-related CO2 emissions by sector, 2020—charts - data & statistics. https://www.iea.org/data-and-statistics/charts/global-energy-related-co2-emissions-by-sector-2020

2022 I (2022) Cement, IEA report, Paris. https://www.iea.org/reports/cement

Murtagh N, Scott L, Fan J (2020) Sustainable and resilient construction: current status and future challenges. J Clean Prod 268:122264

Alyousef R et al (2021) Potential use of recycled plastic and rubber aggregate in cementitious materials for sustainable construction: a review. J Clean Prod 329:129736

Viswanath P (2007) Development of polymer cement composites. PhD Thesis, CiteSeer

Kiruthika C, Prabha SL, Neelamegam M (2021) Different aspects of polyester polymer concrete for sustainable construction. Mater Today Proc 43:1622–1625

Irfan M (2012) Chemistry and technology of thermosetting polymers in construction applications. Springer Science & Business Media, Berlin

Sarde B, Patil Y (2019) Recent research status on polymer composite used in concrete—an overview. Mater Today Proc 18:3780–3790

WOC CTM (2023) Biobased polyurethane in construction. https://www.worldofchemicals.com/media/biobased-polyurethane-in-construction/330.html

Yadav M, Agarwal M (2021) Biobased building materials for sustainable future: an overview. Mater Today Proc 43:2895–2902

Research GV (2023) Bio-based polyurethane market size and share [2023 report]. https://www.grandviewresearch.com/industry-analysis/bio-based-polyurethane-industry

Peyrton J, Avérous L (2021) Structure-properties relationships of cellular materials from biobased polyurethane foams. Mater Sci Eng R Rep 145:100608

Pfister DP, Xia Y, Larock RC (2011) Recent advances in vegetable oil-based polyurethanes. ChemSusChem 4:703–717

Calderón V, Gutiérrez-González S, Gadea J, Ángel Rodríguez Junco C (2018) 10—construction applications of polyurethane foam wastes. In: Thomas S, Rane AV, Kanny K, Abitha VK, Thomas MG (eds) Recycling of polyurethane foams plastics design library. William Andrew Publishing, Oxford, pp 115–125

Akindoyo JO et al (2016) Polyurethane types, synthesis and applications—a review. RSC Adv 6:114453–114482

Gama NV, Ferreira A, Barros-Timmons A (2018) Polyurethane foams: past, present, and future. Materials 11:1841

Li X et al (2021) Recent applications and developments of polyurethane materials in pavement engineering. Constr Build Mater 304:124639

Krishnadevi K, Devaraju S, Sriharshitha S, Alagar M, Keerthi Priya Y (2020) Environmentally sustainable rice husk ash reinforced cardanol based polybenzoxazine bio-composites for insulation applications. Polym Bull 77:2501–2520

Chiacchiarelli L (2019) 8–sustainable, nanostructured, and bio-based polyurethanes for energy-efficient sandwich structures applied to the construction industry. In: Verma D, Fortunati E, Jain S, Zhang X (eds) Biomass, biopolymer-based materials, and bioenergy. Woodhead Publishing series in composites science and engineering. Woodhead Publishing, Sawston, pp 135–160

Miao S, Wang P, Su Z, Zhang S (2014) Vegetable-oil-based polymers as future polymeric biomaterials. Acta Biomater 10:1692–1704

Petrović ZS (2008) Polyurethanes from vegetable oils. Polym Rev 48:109–155

Zhang C, Madbouly SA, Kessler MR (2015) Biobased polyurethanes prepared from different vegetable oils. ACS Appl Mater Interfaces 7:1226–1233

Maisonneuve L, Chollet G, Grau E, Cramail H (2016) Vegetable oils: a source of polyols for polyurethane materials. OCL 23:D508

Moreno DC, Velasco MA, Malagon-Romero DH (2020) Production of polyurethanes from used vegetable oil-based polyols. Chem Eng Trans 79:337–342

Yang Y et al (2023) Valorization of lignin for renewable non-isocyanate polyurethanes: a state-of-the-art review. Mater Today Sustain 22:100367

Khatoon H, Iqbal S, Irfan M, Darda A, Rawat NK (2021) A review on the production, properties and applications of non-isocyanate polyurethane: a greener perspective. Prog Org Coat 154:106124

Ma Y et al (2022) Biomass based polyols and biomass based polyurethane materials as a route towards sustainability. React Funct Polym 175:105285

Desroches M, Escouvois M, Auvergne R, Caillol S, Boutevin B (2012) From vegetable oils to polyurethanes: synthetic routes to polyols and main industrial products. Polym Rev 52:38–79

Fridrihsone A, Romagnoli F, Kirsanovs V, Cabulis U (2020) Life cycle assessment of vegetable oil based polyols for polyurethane production. J Clean Prod 266:121403

Xia Y, Larock RC (2010) Vegetable oil-based polymeric materials: synthesis, properties, and applications. Green Chem 12:1893–1909

de Carvalho JPRG et al (2022) Methodological analysis of composites green polyurethane resin reinforced with jute fabric. Case Stud Constr Mater 17:e01512

Sardon H, Mecerreyes D, Basterretxea A, Averous L, Jehanno C (2021) From lab to market: current strategies for the production of biobased polyols. ACS Sustain Chem Eng 9:10664–10677

Morales-Cerrada R, Tavernier R, Caillol S (2021) Fully bio-based thermosetting polyurethanes from bio-based polyols and isocyanates. Polymers 13:1255

Phung Hai TA et al (2021) Renewable polyurethanes from sustainable biological precursors. Biomacromolecules 22:1770–1794

Simón D, Borreguero A, De Lucas A, Rodríguez J (2018) Recycling of polyurethanes from laboratory to industry, a journey towards the sustainability. Waste Manag 76:147–171

Kemona A, Piotrowska M (2020) Polyurethane recycling and disposal: methods and prospects. Polymers 12:1752

Fonseca LP et al (2023) Reducing the carbon footprint of polyurethanes by chemical and biological depolymerization: fact or fiction? Curr Opin Green Sustain Chem 41:100802

Suttie E et al (2017) 9–environmental assessment of bio-based building materials. In: Jones D, Brischke C (eds) Performance of bio-based building materials. Woodhead Publishing, Sawston, pp 547–591

Wray HE, Luzzi S, D’Arrigo P, Griffini G (2023) Life cycle environmental impact considerations in the design of novel biobased polyurethane coatings. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.3c00619

Final report summary—BIOPURFIL (bio-based polyurethane composites with natural fillers) (2023). https://cordis.europa.eu/project/id/318996/reporting/fr

BIOMAT TB (2023). https://www.biomat-testbed.eu/biomat-open-innovation-test-bed

Territorial circular ecosystems for end-of-life foam (circular foam) circularise (2023). https://www.circularise.com/resource/systemic-expansion-of-territorial-circular-ecosystems-for-end-of-life-foam-circular-foam

Covestro home (2023). https://www.covestro.com/en

WeylChem | fine chemical products & services | fine chemical company - WeylChem - WeylChem (2023). https://www.weylchem.com/

BASF - INDIA (2023). https://www.basf.com/in/en.html

Dow home (2023). https://www.dow.com/en-us.html

Andersons J, Kirpluks M, Cabulis P, Kalnins K, Cabulis U (2020) Bio-based rigid high-density polyurethane foams as a structural thermal break material. Constr Build Mater 260:120471

Manalo A (2013) Structural behaviour of a prefabricated composite wall system made from rigid polyurethane foam and magnesium oxide board. Constr Build Mater 41:642–653

Sharafi P, Nemati S, Samali B, Ghodrat M (2018) Development of an innovative modular foam-filled panelized system for rapidly assembled postdisaster housing. Buildings 8:97

Germán-Ayuso L, Cuevas JM, Cobos R, Marcos-Fernández A, Vilas-Vilela JL (2022) Functional properties of coatings based on novel waterborne polyurethane dispersions with green cosolvents. Prog Org Coat 173:107218

Raychura AJ, Jauhari S, Prajapati VS, Dholakiya BZ (2018) Synthesis and performance evaluation of vegetable oil based wood finish polyurethane coating. Bioresour Technol Rep 3:88–94

Godinho B, Gama N, Barros-Timmons A, Ferreira A (2021) Recycling of different types of polyurethane foam wastes via acidolysis to produce polyurethane coatings. Sustain Mater Technol 29:e00330

Patil CK et al (2021) Chemical transformation of renewable algae oil to polyetheramide polyols for polyurethane coatings. Prog Org Coat 151:106084

Mahajan MS, Gite VV (2022) Self-healing polyurethane coatings of eugenol-based polyol incorporated with linseed oil encapsulated cardanol-formaldehyde microcapsules: a sustainable approach. Prog Org Coat 162:106534

Zhou M et al (2022) Castor oil-based transparent and omniphobic polyurethane coatings with high hardness, anti-smudge and anti-corrosive properties. Prog Org Coat 172:107120

Chen B, Liao M, Sun J, Shi S (2023) A novel biomass polyurethane-based composite coating with superior radiative cooling, anti-corrosion and recyclability for surface protection. Prog Org Coat 174:107250

Somarathna H, Raman S, Mohotti D, Mutalib A, Badri K (2021) Behaviour of concrete specimens retrofitted with bio-based polyurethane coatings under dynamic loads. Constr Build Mater 270:121860

Ding H, Wang J, Wang C, Chu F (2016) Synthesis of a novel phosphorus and nitrogen-containing bio-based polyols and its application in flame retardant polyurethane sealant. Polym Degrad Stab 124:43–50

Rabello LG, da Conceição Ribeiro RC (2021) A novel vermiculite/vegetable polyurethane resin-composite for thermal insulation eco-brick production. Composites B 221:109035

Rabello LG, da Conceição Ribeiro RC (2022) Bio-based polyurethane resin: an ecological binder for a novel class of building materials-composites. Mater Lett 311:131566

Gamit N, Sarde B, Patil YD, Dholakiya BZ (2023) A novel approach towards the use of an agro-industrial waste-based polymer composite delineated from palm oil fuel ash and red mud for sustainable construction applications. Asian J Civ Eng. https://doi.org/10.1007/s42107-023-00642-0

Mounanga P, Gbongbon W, Poullain P, Turcry P (2008) Proportioning and characterization of lightweight concrete mixtures made with rigid polyurethane foam wastes. Cement Concr Compos 30:806–814

Arroyo R, Horgnies M, Junco C, Rodríguez A, Calderón V (2019) Lightweight structural eco-mortars made with polyurethane wastes and non-ionic surfactants. Constr Build Mater 197:157–163

Junco C, Gadea J, Rodríguez A, Gutiérrez-González S, Calderón V (2012) Durability of lightweight masonry mortars made with white recycled polyurethane foam. Cement Concr Compos 34:1174–1179

Jiang W et al (2021) Effect of crumb rubber powder on mechanical properties and pore structure of polyurethane-based polymer mortar for repair. Constr Build Mater 309:125169

Meng Y et al (2022) Research on modification mechanism and performance of an innovative bio-based polyurethane modified asphalt: a sustainable way to reducing dependence on petroleum asphalt. Constr Build Mater 350:128830

Xia L, Cao D, Zhang H, Guo Y (2016) Study on the classical and rheological properties of castor oil-polyurethane pre polymer (C-PU) modified asphalt. Constr Build Mater 112:949–955

Liu J, Lv S, Peng X, Yang S (2021) Improvements on performance of bio-asphalt modified by castor oil-based polyurethane: an efficient approach for bio-oil utilization. Constr Build Mater 305:124784

Kök BV, Aydoğmuş E, Yilmaz M, Akpolat M (2021) Investigation on the properties of new palm-oil-based polyurethane modified bitumen. Constr Build Mater 289:123152

Gama N, Ferreira A, Barros-Timmons A (2019) Cure and performance of castor oil polyurethane adhesive. Int J Adhes Adhes 95:102413

Beran R, Zárybnická L, Machová D, Večeřa M, Kalenda P (2021) Wood adhesives from waste-free recycling depolymerisation of flexible polyurethane foams. J Clean Prod 305:127142

Alsuhaibani AM et al (2023) Green buildings model: impact of rigid polyurethane foam on indoor environment and sustainable development in energy sector. Heliyon 9:e14451

Zhu M et al (2021) Recent advances in fire-retardant rigid polyurethane foam. J Mater Sci Technol 112:315–328

Visakh P, Semkin A, Rezaev I, Fateev A (2019) Review on soft polyurethane flame retardant. Constr Build Mater 227:116673

Alinejad M et al (2019) Lignin-based polyurethanes: opportunities for bio-based foams, elastomers, coatings and adhesives. Polymers 11:1202

Kuranchie C, Yaya A, Bensah YD (2021) The effect of natural fibre reinforcement on polyurethane composite foams—a review. Sci Afr 11:e00722

Deroubaix A et al (2021) Large uncertainties in trends of energy demand for heating and cooling under climate change. Nat Commun 12:5197

Technology S (2021) Polyurethane durability and building durability. https://blog.synthesia.com/en/polyurethane-durability-buildings

Garrido M, Correia JR, Keller T (2016) Effect of service temperature on the shear creep response of rigid polyurethane foam used in composite sandwich floor panels. Constr Build Mater 118:235–244

Oliveira PR, May M, Panzera TH, Hiermaier S (2022) Bio-based/green sandwich structures: a review. Thin-Walled Struct 177:109426

Murmu SB (2022) Alternatives derived from renewable natural fibre to replace conventional polyurethane rigid foam insulation. Clean Eng Technol 8:100513

Paraskar PM, Prabhudesai MS, Hatkar VM, Kulkarni RD (2021) Vegetable oil based polyurethane coatings—a sustainable approach: a review. Prog Org Coat 156:106267

Wang H et al (2020) A comparative study on UV degradation of organic coatings for concrete: structure, adhesion, and protection performance. Prog Org Coat 149:105892

Shen D et al (2018) Development of shape memory polyurethane based sealant for concrete pavement. Constr Build Mater 174:474–483

Hameed AM, Hamza MT (2019) Characteristics of polymer concrete produced from wasted construction materials. Energy Procedia 157:43–50

Fan G et al (2022) Research on working performance of waterborne aliphatic polyurethane modified concrete. J Build Eng 51:104262

Al-kahtani M, Zhu H, Ibrahim YE, Haruna S (2022) Experimental study on the strength and durability-related properties of ordinary Portland and rapid hardening Portland cement mortar containing polyurethane binder. Case Stud Constr Mater 17:e01530

Haruna SI, Zhu H, Jiang W, Shao J (2021) Evaluation of impact resistance properties of polyurethane-based polymer concrete for the repair of runway subjected to repeated drop-weight impact test. Constr Build Mater 309:125152

Tang J, Liu J, Yu C, Wang R (2017) Influence of cationic polyurethane on mechanical properties of cement based materials and its hydration mechanism. Constr Build Mater 137:494–504

Hussain HK, Liu GW, Yong YW (2014) Experimental study to investigate mechanical properties of new material polyurethane-cement composite (PUC). Constr Build Mater 50:200–208

Yew MK et al (2022) Performance of surface modification on bio-based aggregate for high strength lightweight concrete. Case Stud Constr Mater 16:e00910

Wu F, Yu Q, Liu C (2022) Creep characteristics and constitutive model of bio-based concrete in aqueous environment. Constr Build Mater 320:126213

Gadea J, Rodríguez A, Campos P, Garabito J, Calderón V (2010) Lightweight mortar made with recycled polyurethane foam. Cement Concr Compos 32:672–677

Zhao Y, Gong X, Liu Q (2023) Research on rheological properties and modification mechanism of waterborne polyurethane modified bitumen. Constr Build Mater 371:130775

Huang G, Yang T, He Z, Yu L, Xiao H (2022) Polyurethane as a modifier for road asphalt: a literature review. Constr Build Mater 356:129058

Sizirici B, Fseha Y, Cho C-S, Yildiz I, Byon Y-J (2021) A review of carbon footprint reduction in construction industry, from design to operation. Materials 14:6094

Marson A, Masiero M, Modesti M, Scipioni A, Manzardo A (2021) Life cycle assessment of polyurethane foams from polyols obtained through chemical recycling. ACS Omega 6:1718–1724

Manzardo A et al (2019) Life cycle assessment framework to support the design of biobased rigid polyurethane foams. ACS Omega 4:14114–14123

Noreen A, Zia KM, Zuber M, Tabasum S, Zahoor AF (2016) Bio-based polyurethane: an efficient and environment friendly coating systems: a review. Prog Org Coat 91:25–32

Salzano de Luna M (2022) Recent trends in waterborne and bio-based polyurethane coatings for corrosion protection. Adv Mater Interfaces 9:2101775

Islam S, Walport E, Hart T, Firth R (2021) Circular biobased construction in the North East and Yorkshire (United Kingdom). https://www.ynylep.com/Portals/0/adam/Stories/dZPBWh5Fz0mcAqqNaH1neA/Body/211021_MC2105_NEY_REPORT_FINAL_ISSUE_SPREADS_COMPRESSED.pdf

Rosenboom J-G, Langer R, Traverso G (2022) Bioplastics for a circular economy. Nat Rev Mater 7:117–137

Eggum RA, Gjerde IE, Lundwall LO (2020) Bio-based materials for sustainable concrete. PhD Thesis

Mitsui chemicals (2023). https://www.mitsuichemicals.com/index.htm

Innovative partnership of Selena group and Covestro (2023). https://selena.com/en/innovative-partnership-of-selena-group-and-covestro/

Fruit stone powders—biopowder (2023). https://www.bio-powder.com/en/

Kaur R, Singh P, Tanwar S, Varshney G, Yadav S (2022) Assessment of bio-based polyurethanes: perspective on applications and bio-degradation. Macromol 2:284–314

Keena N et al (2022) A life-cycle approach to investigate the potential of novel biobased construction materials toward a circular built environment. Energies 15:7239

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

MM: conceptualization, structuring, literature search, review writing and editing. VP: structuring, editing and grammar check, guidance and support. BZD: conceptualization, structuring, editing and grammar check, guidance and support.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mistry, M., Prajapati, V. & Dholakiya, B.Z. Redefining Construction: An In-Depth Review of Sustainable Polyurethane Applications. J Polym Environ (2024). https://doi.org/10.1007/s10924-023-03161-w

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-023-03161-w